Characterization of textured anisotropic ferrites using

advertisement

MTEX Workshop 26.02.2016

Characterisation of texture of

strontium hexaferrite with EBSD

and XRD

Timmy Reimann, Arne Bochmann, Jörg Töpfer

Timmy Reimann

0. Outline

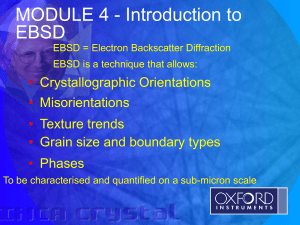

1. Introduction

2. EBSD results

3. XRD results

4. Evaluation with MTEX

5. Summary

6. Outlook

2 / 28

1. Introduction – field of interest

Functional ceramics

Soft ferrites

o Mn-Zn ferrites for multilayer inductors

o M-, Y-, Z-type hexaferrites

H. Bartsch

Hard ferrites

o Sr hexaferrites for permanent magnets

Dia- and Piezoelectrics

o CaCu3Ti4O12

o PZT (PbZrO3)

o Pb free BNBT (Bi0.5Na0.5)TiO3 – BaTiO3

and KNN (K0.5Na0.5NbO3)

multi layer round coil

Thermoelectrics

o CCO (Ca3Co4O9); CaMnO3

Low temperature ceramic cofiring (LTCC)

devices sintered at 900°C

3 / 28

multi layer capacitor

1. Introduction - Hexaferrite

3+ 2−

𝑆𝑟 2+ 𝐹𝑒12

𝑂19

M-Type hexagonal ferrites (Ba/Sr)Fe12O19:

most important material group for permant

magnets

market share:

Sinter Ferrite (47%)

S-Block

Compound-Ferrite (21%)

Sinter-NdFeB (19%)

R-Block

Compound-NdFeB (6%)

Sinter-SECo (6%)

Compound-SECo (1%)

SG: 6/mmm

a = b = 5.8836 Å

c = 23.0376 Å

4 / 28

1. Introduction - Tridelta Maniperm® 882

Data sheet

Maniperm 882 :

1,0

flux density B

remanence:

magnetic field H

coercivity:

HCB = 270-240 kA/m

energy product:

(BH)max = 32 kJ/m2

5 / 28

0,5

B (T)

BR = 405-415 mT

Tridelta Maniperm 882

EAH Jena Permagraph

sample 70A

0,0

-0,5

𝐵 = 𝐽 + 𝜇0 𝐻

𝐽 … 𝑚𝑎𝑔𝑛𝑒𝑡𝑐 𝑝𝑜𝑙𝑎𝑟𝑖𝑠𝑎𝑡𝑖𝑜𝑛

𝜇0 … 𝑚𝑎𝑔𝑛𝑒𝑡𝑖𝑐 𝑓𝑖𝑒𝑙𝑑 𝑐𝑜𝑛𝑠𝑡𝑎𝑛𝑡

-1,0

-600

-400

-200

0

H (kA/m)

200

400

600

1. Introduction – sample preparation

uniaxial pressing with

applied magnetic field

𝐻=𝐼

𝑁

𝑙2 + 𝐷2

𝐼 … 𝑐𝑢𝑟𝑟𝑒𝑛𝑡

𝑁 … 𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑤𝑖𝑛𝑑𝑖𝑛𝑔𝑠

𝑙 … 𝑙𝑒𝑛𝑔𝑡ℎ

𝐷 … 𝑐𝑜𝑖𝑙 𝑑𝑖𝑎𝑚𝑒𝑡𝑒𝑟

sample

current variation:

0 A; 20 A; 40 A; 60 A; 70 A

6 / 28

1. Introduction - sample preparation

uniaxial pressing with

applied magnetic field

H field in z direction

orientation of c axis in powder

particles of slurry in z direction

due to uniaxial magnetocrystalline anistropy of

SrFe12O19

goal:

increase of remanence in z

direction

7 / 28

1. Introduction – magnetic properties

2. quadrant of H – J plot

increase of remanence

with increasing H field in

pressing process

observed

0,40

0,32

task:

characterisation of

texture

J (T)

0,24

0,16

70 A

20 A

0A

0,08

0,00

-350

-300

-250

-200

-150

-100

-50

H (kA/m)

𝐵 = 𝐽 + 𝜇0 𝐻

8 / 28

0

1. Introduction – goals

Characterisation of texture

measurement of texture with EBSD and XRD and evaluation of both data sets

with same procedure

computing ODF

tetermine vector of main orientation

calculating amount of fibre texture

derivation around main orientation and calculating Br according to the ODF

9 / 28

2. EBSD results – 0 A sample

IPFX Map

112 x 84 µm

10 / 28

2. EBSD results – 0 A sample

11 / 28

2. EBSD results – 20 A sample

IPFX Map

12 / 28

2. EBSD results – 20 A sample

13 / 28

2. EBSD results – 70 A sample

IPFX Map

14 / 28

2. EBSD results – 70 A sample

15 / 28

2. EBSD results – ODF (MTEX)

To calculate the ODFs given in the pole figures below a kernel function with a

halfwidth of 5 ° was used.

0A

70 A

16 / 28

20 A

(10-10)

(10-11)

15,0

17,5

17 / 28

20,0

22,5

25,0

27,5

2 (°)

30,0

32,5

35,0

(11-26)

(20-23)

(11-24)

(10-17)

SrFe12O19

(20-20)

(20-21)

(10-18)

(20-22)

(0008)

(11-22)

(11-20)

Hexaferrit 60 A pellet

c-axis in x direction

(10-16)

(10-15)

(0006)

(10-13)

(10-12)

(0004)

intensity (a. u.)

3. XRD results

37,5

3. XRD results – Bruker Multex

Polfigures

(1010)

Calculated polfigure for fibre texture

18 / 28

(1017)

(1124)

3. XRD results – Bruker Multex

phases

rotation axis f

rotation axis

halfwidth: 30°

f.polar = 82,32°

f.azimuth = 177,49°

19 / 28

4. Evaluation with MTEX

Polfigures plotted with MTEX (halfwidth = 5°)

Calculation of ODF

Plot of polfigures

20 / 28

4. Evaluation with MTEX

polefigure of ODF

Multex Fit

fibre: 72 % , halfwidth: 30 %

MTEX Fit

ODF_mea = x*ODF_Fibe + (1-x)*ODF_Uni*

fibre:69 %, halfwidth: 17 %

uniform: 31%

21 / 28

*matlab script at the end

4. Evaluation with MTEX

Anteilfibre = [];

i = 1;

for theta = 5 : 5 : 90

theta_array(i) = theta;

Anteilfibre(i) = fibreVolume(odf_measured, Miller(0,0,1,cs), o_min_vector,…

theta*degree) * 100;

i = i+1;

end

16

60 A

14

80

volume fraction (%)

cumulative sum

fibre amount (vol.%)

100

60

40

20

12

10

8

6

4

2

0

0

0

20

40

halfwidth (°)

22 / 28

60

80

20

40

60

halfwidth (°)

80

4. Evaluation with MTEX

Br (theo.) = 0.437 T

in c direction

𝐵𝑅𝑖 = 𝐵𝑅𝑡ℎ𝑒𝑜 cos 𝜑𝑖

𝑁90°

𝐵𝑅𝑔𝑒𝑠 =

𝐵𝑅𝑡ℎ𝑒𝑜 cos(Δ𝜑 ∗ 𝑖)

𝑖

𝐵𝑅𝑔𝑒𝑠 = 0.413 𝑇;

𝐵𝑅𝑔𝑒𝑠

𝐵𝑅𝑡ℎ𝑒𝑜

0,07

0,40

0,06

0,35

60 A

0,05

0,30

0,25

0,04

0,20

0,03

0,15

0,02

0,10

0,01

0,05

0,00

0,00

0

20

40

60

halfwidth (°)

23 / 28

80

cmulative sum Brges (T)

Anteil an Brges - Bri (T)

𝜑

100 = 95 %

5. Summary – 60 A sample

EBSD polefigure of ODF

XRD polefigure of ODF

MTEX Fit

fibre: 75 %, halfwidth = 20,5°

uniform: 25 %

fibre:69 %, halfwidth: 17°

uniform: 31%

24 / 28

5. Summary – 60 A sample

17,5

100

Hexaferrit 60 A

XRD

EBSD

volume fraction (%)

cumulative sum

fibre (vol.%)

80

Hexaferrit 60 A

XRD

EBSD

15,0

60

40

20

12,5

10,0

7,5

5,0

2,5

0

0

10

20

30

40

50

60

70

80

90

0,0

0

halfwidth (°)

20

40

60

halfwidth (°)

cumulative sum Br (T)

0,4

Br (XRD) = 0.413 T

Br (EBSD) = 0.416 T

0,3

Measured Br:

Br (Robograph) = 0.405 T

0,2

Hexaferrit 60 A

XRD

EBSD

0,1

0,0

0

10

20

30

40

50

halfwidth (°)

25 / 28

60

70

80

90

80

6. outlook

XRD Pole figures of 70 A sample

measuring of a sample with c in z direction with XRD and EBSD

use of Co-radiation instead of Cu-radiation

preparation of an isotrop SrFe12O19 sample for calibration of XRD polefigures

26 / 28

6. outlook

Characterisation of screen printed thick

film hexaferrites for circulators

Characterisation of KNN piezoelectics

15 mm

27 / 28

Thanks!

28 / 28

Script for MTEX Fit

%% Fitten Fibre

Miller_c_Achse = Miller (0 ,0 , 1 ,cs);

fibrevector = odf_max_orientation*Miller_c_Achse;

odf_fibre = fibreODF(Miller(0,0,1,cs),fibrevector,'halfwidth',20*degree);

% definition Anfangsvektor, x(1): Amplituden; x(2), x(3), x(4): Eulerwinkel (°), x(5): Halfwidth unimodale ODF

[h1, h2, h3] = Euler(odf_max_orientation,'Bunge');

x0 = [0 h1/degree h2/degree h3/degree 10];

% Definition Nebenbedingungen: 0<= x(1) <= 1; 0<= x(5) <= 45;

A = [-1 0 0 0 0; ...

1 0 0 0 0; ...

0 0 0 0 -1; ...

0 0 0 0 1];

b = [0;1;0;45];

min_func = @(x)calc_ODF_Error(x,odf_measured, ss,cs);

[x,fval,exitflag,output] = fmincon(min_func,x0,A,b,[],[],[],[],[],optimset('Algorithm','interior-point','Display','iterdetailed'));

o_min = orientation('Euler',x(2)*degree,x(3)*degree,x(4)*degree,cs,ss);

o_min_vector = o_min*Miller_c_Achse;

ampl_min = x(1);

halfwidth_min = x(5);

odf_min = ampl_min*fibreODF(Miller(0,0,1,cs), o_min_vector,'halfwidth',halfwidth_min*degree) + (1ampl_min)*uniformODF(cs,ss);

29 / 28

30 / 28

31 / 28