Project 5 - University of Cincinnati

advertisement

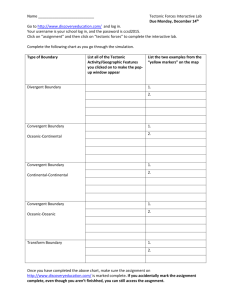

PROJECT SUMMARY REPORT SIMULATION OF FLUID FLOW IN THE SCREENBOUNDED CHANNEL IN A FIBER SEPERATOR Submitted To The 2013 Academic Year NSF AY-REU Program Part of NSF Type 1 STEP Grant Sponsored By the National Science Foundation Grant ID No.: DUE-0756921 College of Engineering and Applied Science University of Cincinnati Cincinnati, Ohio Prepared By Lana Sneath, Pre-Junior, Biomedical Engineering Sandra Hernandez, Pre-Junior, Biomedical Engineering Report Reviewed By: ___________________________ Dr. Urmila Ghia REU Faculty Mentor Professor of Mechanical Engineering School of Dynamic Systems University of Cincinnati January 7 – April 26, 2013 1 Chapter 1 1.1 Objectives The motivation behind this study is to understand the behavior of the fluid flow within the deep open channel in the BMC apparatus. The goal of the present study is to numerically simulate the three-dimensional flow in the BMC deep open channel of aspect ratio (H/B) 10. The BMC deep open channel is first modeled as a channel with both vertical side boundaries as solid walls. Next, a portion of one of the solid walls is replaced by a porous-jump boundary condition, which represents the screen in the BMC apparatus. The focus of the experiment is to analyze the shear stress distribution on the screen, modeled as a porous boundary, and determine the effectiveness of the BMC for length-based separation of fibers. The objectives of the study are to: a) Learn the fundamentals of fluid dynamics. b) Learn the fundamentals of solving fluid dynamic problems numerically. c) Simulate and study the flow in the open channel of the BMC apparatus, modeling the screen as a solid wall boundary (i) d) Model the screen as a porous boundary (ii) 1.2 Materials Commercially available Computational Fluid Dynamics (CFD) tools FLUENT and Gambit are used for the simulations in this study. 1.3 Methods The goal of this study is to numerically simulate the fluid flow in the screen-bounded channel within the BMC fiber separator. To numerically study the fluid flow, Computational Fluid Dynamic (CFD) software FLUENT and Gambit are used. Computational Fluid Dynamics is the “concepts, procedures, and applications of computational methods in fluids and heat transfer” [9]. CFD tools apply the principles of engineering to the modeling of fluid flow. [10]. Using the CFD tool FLUENT, the 3D, unsteady, incompressible Reynolds-Averaged Navier-Stokes Equations (RANS) are solved to determine the three-dimensional flow in the deep open channel of aspect ratio 10. The Semi-Implicit Pressure-Linked (SIMPLE) algorithm is used to achieve pressurevelocity coupling. The solution is deemed converged, when the residuals of the continuity equation and the conservation of momentum equation reach 10e-6. Chapter 2 Flow in the BMC Open Channel – Solid Side Walls 2.1 Geometry and Computational Grid The deep open channel geometry is created in Gambit with dimensions of 0.217 x 0.02 x .2 m in the x, z, and y directions, respectively, giving the channel geometry an aspect ratio of 10. A computational grid is created, with grid spacing of 50, 180, and 45 in the x, y, and z directions, respectively. The first step size of the grid is 0.00005 m away from the boundaries in the y direction, and 0.00007 m in the z direction. The small step sizes allow for more computations to be taken along the boundary edges where the fluid flow has greater variation. The grid spacing along the x direction has a successive ratio of 1, meaning that the grid points are evenly spaced. The fluctuations in the fluid flow along the distance of the channel are moderated as compared to the y- and z-directions, hence it was not necessary to cluster the points around the edges. The boundary conditions used for modeling the wire-mesh wall as a solid boundary are shown in Figure 1. The average velocity at the inlet is specified to be 0.25 m/s. The Reynolds number for the BMC apparatus is equal to 9982, classifying it as a turbulent flow. The fluid flow is computed in FLUENT at every discrete grid point, and the Reynolds-stress model includes the effects of turbulence. The turbulence boundary conditions were specified in the form of turbulence intensity and viscosity of 5% and 10, respectively, for the inlet and outlet boundaries. 2 Free-Slip Wall, v=0, du/dy=0, dw/dy=0 No-Slip Wall, u = v = w = 0 Inlet, u = U, v = w =0 Outlet, pstat = 0 Figure 1. Boundary conditions applied on the BMC open channel 2.3 Results and Discussion The velocity and vorticity results are analyzed in cross planes at x= 0.2 m, y = 0 to 20 m, and z= 0.02 m. Figures 2 shows the x-velocity contours on the cross plane of the open channel near the free surface, respectively. Velocity is lowest at the edges of the channel due to friction of the stationary wall. The velocity contours are bulged towards the corners near the free surface at the top of the channels, while elsewhere along the vertical wall boundaries, the contours gradually shift towards the center of the plane. The free surface at the top of the channel is modeled by a zero-shear stress wall, which attracts the high-momentum fluid from the center of the open channel. In order to preserve the channel continuity, low momentum fluid from the corner regions flows towards the center of the channel. This motion of fluid flow creates a circulatory effect near the corners, which causes the bulge in velocity contours near the free surface. Figure 2. X- Velocity Contours on Top Half of channel Figure 3. X-Vorticity Contours on Top Half of channel Figure 3 shows the x-vorticity on the cross plane of the BMC open channel. Vorticity is defined as the tendency of a fluid to rotate [11]. In the corners near the free surface, the vortex pair is not symmetrical about the angle bisector. The variation in vorticity along the top of the channel is due to the different boundary conditions, which changes the behavior of the fluid flow. Shear stress, as shown in Figure 4 in blue, was computed along the x-direction of the channel. Total shear stress, including 𝜏𝑧𝑥 , 𝜏𝑧𝑦 , and 𝜏𝑧𝑧 , was calculated along the z=0.02 m sidewall at x = 0 to 0.217 m, y = 0.1 m (mid-plane). The computations from FLUENT for each partial derivative in respect to z were written out as a text file, and uploaded into Microsoft Excel in order to calculate 𝜏 for each shear stress component on the sidewall. Each of the three components was squared and added together. The square root of the summation is taken to obtain the total shear stress along the x- direction acting on the sidewall at y = 0.1m. 3 2 14 12 1.5 10 8 1 6 4 0.5 2 0 0 0 0.1 X-Position (m) Off Plane Shear Stress Angle (degrees) Total X-Wall Shear Stress (Pascals) Total Shear Stress Total Stress Off Plane Shear Stress Angle 0.2 Figure 4. Total Shear Stress along (left y-axis) and off plane shear stress angle (right y-axis); line at y= 0.1 m (mid-plane), z= 0.02 m The off-plane angle, shown in red, is the angle between resultant shear stress vectors and the xy plane. These results show the shear stress angle between the free surface and the wall in the BMC channel with respect to the x-position in the channel geometry. It is shown that the shear stress angle is greatest at the inlet, and quickly drops down to around 8 degrees as the x-position increases. The highest off-plane angle occurs at the inlet, x= 0m, and quickly drops down to 8.36 degrees around x = 0.0116 m. Chapter 3 Flow in the BMC Open Channel with a Screen on a Side Wall 3.1 Geometry and Computational Grid As a second step, portion of the sidewall of the channel containing the screen was replaced with a porous boundary. The porous boundary represents the screen in the BMC apparatus. The porous boundary is modeled with 1 inch (0.0254 m) margins lengthwise and a 1 inch margin from the bottom of the channel. The dimensions of the boundary are x= 0.1662 m, y= 0.1746 m, and a wire diameter 0.0004572 m. The grid spacing for the channel with a porous boundary maintains the same grid spacing and ratio of points per inch as the previous mesh. 3.2 Boundary Conditions The boundary conditions for all parameters except a portion of a side wall are the same as the previous case with solid side walls, as seen in figure 5. In Fluent, one side of the screen was specified as a porous-jump boundary condition, and the other as a pressure-outlet. In order for FLUENT to solve the Reynolds Stress Equations for the fluid flow in the channel with a porous boundary, the permeability, pressure-jump coefficient, and the thickness of the porous boundary need to first be determined. Calculating Permeability (K) and Pressure-Jump Coefficient (𝐶2 ): The standard screen thickness for a 16 Mesh is 0.0009144 m (0.036 Inch) and the wire diameter is 0.0004572m (0.0180 Inch). When evaluating through-plane flow through a 2D planar 𝐾 structure, the 2 value is given to be 0.0056 with F=0.118. The equation used to calculate the 𝑑 permeability (K) and the pressure-jump coefficient are: 2𝐹 𝐾 𝐾 𝐶2 = and 2 = 2 √𝐾 𝑑 𝑑 4 To first solve for K, the given wire diameter (d) and the a planar 2D structure are imputed into the equation 𝐾 0.0046 = 2 𝐾 𝑑2 value for a through-plance flow through (0.0004572) 𝐾 = 9.6154𝑒 −10 𝑚2 This means the face permeability (K) of the screen mesh is 9.6154𝑒 −10 𝑚2 The pressure-jump coefficient (𝐶2 ) is calculated by replacing F with the given 0.118 value and using the calculated K 2(0.118) 1 𝐶2 = = 7610.739 −10 2 √(9.6154𝑒 𝑚 ) 𝑚 These values are then entered into FLUENT along with the overall screen thickness of 0.0009144 m to analyze the flow in the 3D open channel with the screen modeled as a porous-jump boundary. Free-Slip Wall, u= v = w = 0 No-Slip Wall, u = v = w = 0 Inlet, u = U, v = w =0 Outlet, pstat = 0 Porous-Jump, K = 9.6e-10, C2=7610.7 1/m, thickness = 9e-4 m 𝐾 = 9.6154𝑒 −10 𝑚2 Figure 5. Boundary Conditions of Channel with Porous Boundary The turbulence boundary conditions were specified in the form of turbulence intensity and viscosity of 0.5% and 1, respectively, for the inlet and outlet boundaries. The edges surrounding the porous boundary are modeled as solid no-slip walls with u= v= w=0. 3.3 Results and Discussion Figures 6 shows the x-velocity contours on the cross plane of the open channel near the free surface and the channel base, respectively. The velocity is similar to the two wall case with the velocity being highest towards the center and lowest at the edges of the walls. The velocity contours are bulged towards the corners near the free surface at the top of the channels, while elsewhere along the vertical wall boundaries, the contours gradually shift towards the center of the plane. However, unlike the previous case, the velocity contours along each wall are not symmetric. This can be attributed to the addition of the porous boundary. Figure 6. X- Velocity Contours on Top Half of channel 5 Figure 7. X-Vorticity Contours on Top Half of channel Figure 7 shows the x-vorticity on the cross plane of the BMC open channel. The porous boundary is modeled from x= 0.0254 m to 0.1916 m. The vorticity contours were taken at a plane at x= 0.20m in line with the outlet, right after the porous boundary ends. The addition of the porous boundary greatly increased the vorticity along the sidewall of the channel. Conclusion The objective of this study was to numerically study the flow through the deep open channel of the BMC with an aspect ratio of 10. The BMC channel geometry is initially modeled as two sidewalls and the bottom wall that are no-slip stationary walls, where the u, v, and w components of velocity are equal to zero. As a second step, the BMC channel geometry is modified to have one of the sidewalls contain a porous boundary condition. Initially it was found in the first model with solid sidewalls that the x-velocity contours were highest in magnitude towards the center of the channel and lowest at the stationary, nonporous sidewalls. In the second porous wall model, it was found that the x-velocity contours followed the same behavior as the previous case. However, once the flow reaches the porous boundary, the x-velocity of the flow begins to fluctuate. In both of the x-velocity contour plots, bulges are observed near the free surface. The bulges in the x-velocity contour plots can be attributed to the presence of a free surface attracting higher momentum fluid, pushing the lower momentum fluid towards the center of the channel [1]. The shear stress distribution on the vertical sidewalls near the free surface is affected by this circulatory effect. Furthermore, the circulation of fluid is observed in the x-vorticiy contour plots, which show the highest vorticity in the corners near the free surface. In the solid side walls channel geometry, the off-plane angle is greatest at the inlet and drops down and remains around 8 degrees as the x-position increases. These results indicate that the shear stress is mainly aligned tangential to the fluid flow. Future Work The future work of this study is to further analyze the off-plane and shear stress distribution of the channel modeled with a porous boundary. We hope to further understand the effects of the porous boundary on fluid flow behavior and compare the porous boundary results to those of a 3x3 array of square apertures. Bibliography 1. Jana, C. (2011), “Numerical Study of Three-Dimensional Flow Through a Deep Open ChannelIncluding a Wire-Mesh Segment on One Side Wall.” M.S. Mechanical Engineering Thesis, University of Cincinnati. 2. Dodson, R., Atkinson, M., Levin, J. (2003), “Asbestos Fiber Length as Related to Potential Pathogenicity: A Critical Review.” American Journal of Industrial Medicine, Vol. 44, p. 291-297 3. http://www.nlm.nih.gov/medlineplus/asbestos.html 4. Guo, J., Julien, PY. (2005). “Shear stress in smooth rectangular open-channel flows.” American Society of Civil Engineers, 131(1), 30-37. 5. Janna, W. S. (2009) “Introduction to Fluid Mechanics”, CRC press, 4th Edition. 6. White, F. M. (2003) “ Fluid Mechanics”, McGraw-Hill, 5th Edition. 7. Fluent 6.3 User’s Guide. 8. Gambit 2.4 User’s Guide. 9. Chung, T. J. (2010) “Computational Fluid Dynamics”, Cambridge University Press, 2 nd Edition. 10. Birchall, D. (2009) “Computational fluid dynamics”, The British Institute of Radiology, 82, S1S2. 11. “Vorticity.” Def. 1. Meriam Webster Online, Merriam Webster 12. Blake, T., Castranova, V., Baron, P., Schwegler-Berry, D., Deye, G.J., Li, C., and Jones, W., (1998), “Effect of Fiber Length on Glass Microfiber Cytotoxicity,” Journal of Toxicological Environmental Health, Part A, Vol. 54, Issue 4. 13. www.uceindia.com/fiber-classifier-bauer-mcnett-type.htm 14. Paschkewitz, J.S., Dubiel, Y., Shaqfeh, E., (2005), “The dynamic mechanism for turbulent drag reduction using rigid fibers based on Lanrangian conditional statistics”, American Institute of Physics, Vol. 17. 6