file - IFFS-UIT

advertisement

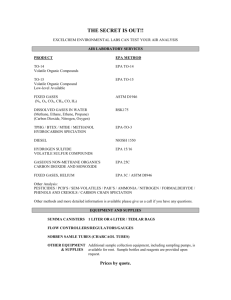

Supplementary materials and methods: <A>Laboratory conditions <B>CODA filter system: Two different sets of filter kits were used to make CODA filter changes throughout the year. The first and most frequently used kit is the Quarterly Kit (LifeGlobal®, Guelph, Canada), which consists of the Main Stage filters. They consiste of two prefilters and one chemical filter, made of five canisters containing 13.61 kg of a carbon and potassium permanganate mix. As the name implies, this set of filters was changed every 3 months (at the beginning of each series). The second kit is the Annual Kit (LifeGlobal®, Guelph, Canada), and consists of the Quarterly Kit plus one HEPA filter. Once a year (December/January), this kit was used to change the CODA filters instead of the Quarterly Kit. The IVF laboratory had four CODA Towers (model CT300) as well as two CODA Lo-boys. The IVF laboratory at WRAMC was 38.5 m2 and each CODA Tower is most effective in rooms up to 63 m2. <B>Laboratory set up The assisted reproduction technique suite consists of an operative suite, IVF laboratory, procedure (embryo transfer) room, and a transition hallway anteroom. These four rooms are interconnected and under positive pressure control separate from the remaining areas of the assisted reproduction technique suite. The IVF laboratory is 58 m2. The positive pressure differential of the IVF laboratory from the procedure room is 0.1098” WC (water column) with a differential of 0.0772”WC from the procedure room and outside hallway. Air return vents are located 12” above the floor level in an effort to help keep them clean. Air supply vents are located in the ceiling of the IVF laboratory with a diffuser grill to diminish direct air currents. <B>HVAC filtration system The new air filtration system consists of a total of nine (three high by three wide) MERV-8, 2-inch throwaway 30% pleated filters. The ultraviolet light is located in the HVAC unit after the pre-filters but before the point in which outside and recirculated air mixes and before the coconut based carbon filters. The chemical beds, which are located after the cooling and heating coils, are configured as two, single-wide x dualhigh unit, with each chemical bed consisting of 24 Puradfil® Modules (PK-12 disposable units). There are a total of 48 units between the two chemical beds for a total of 415kg of carbon plus potassium permanganate mix per bed. The two chemical beds in inline formation have an increased residency time of about 32 s. The chemical beds are changed on manufacturer’s recommendations with a chemical module sample sent to the manufacturer once a year to determine remaining chemical bed activity. High Efficiency Rigid Cell Filters (Legacy Model – Airguard ) capture any remaining large particulates before reaching the HEPA filters. These filters have a MERV rating of 14. The air is humidified with the humidifier located just after the HEFA filters but before the HEPA filters. The clean steam is from a domestic water supply, which is treated by an Ecodyne water treatment system. The water is then turned into steam by a Dristeem system and piped to the entry point of the HVAC unit. <B>Materials used The key to a low volatile organic compound (VOC) workplace rests with the use of selective materials applied correctly and then allowed to outgas. The paints used inside the IVF laboratory were water based paint swith low VOC formulations. Oilbased paints were not acceptable. Painting earlier in the process allows for a longer time to off gas. We used sheet vinyl flooring from Medintech. Installation was completed with the recommended adhesive from Armstrong Inc. To aid the ‘burn-in’, the vinyl sheets were laid out in a clean secure area to allow for off-gassing before installation. To effectively pressurize the IVF laboratory suite, each and every penetration into the IVF Laboratory Suite was sealed. This included all of the walls, floors, decks, ceiling, and electrical boxes inside and around the IVF laboratory. Plaster Sealing (mud was used to seal the gaps between sheet rock panels.) and GE Silicone Clear were used for sealants. No wood, particle board or adhesive casework was used for the construction. Epoxy or acrylic-coated metal was acceptable for laboratory furniture, with stone composites or epoxy-based tops for the counter tops. Particleboard or wood was not acceptable. It was verified that laboratory furniture did not contain these materials. A list of materials successfully used in modern IVF laboratories is provided in Supplementary Table 1. <B>Air quality testing The following air quality testing methods were taken directly from the supplied report by Alpha Environmental Specialist: ‘Sample locations were assessed for total Volatile Organic Compounds (VOCs) by US EPA TO-15 and for aldehydes by US EPA TO-11A. VOC sampling was completed by taking 6 L of air of 24-hours using a critical orifice. The sample canister is a chemically clean, silicate stainless steel container that has been evacuated to vacuum. This technique does not use a pump. All tubing connectors, when used, were made of Teflon or silicone tubing that had previously been purged with 99.999+% nitrogen to insure no residual material was retained. Sample vessels were closed at the end of sampling and packaged for shipment to be analyzed. The TO-15 procedure is outlined in Compendium of Methods for the Determination of Toxic Organic Compounds in Ambient Air – EPA 300/4-84-041, April 1984/1988. The instrument used was a Hewlett Packard Model 5989 GC/MS with an Entech 7000 cryogenic concentrator. A 100% dimethylpolysiloxane capillary column was used. A blank was also run to verify the instrument baseline. All of the standards were less than the detection limit on the blank. Unknown materials (Tentatively Identified Compounds – TIC) were identified by matching the mass spectra to a library of materials and picking the most accurate fit for tentative identification. Quality control was completed using the following procedures: a. Mass Spectrometer Tuning: Every 24 hours the mass calibration was checked with 4-bromofluorobenzene. This compound was used to check the accuracy of the generated spectra at several points on the mass spectra. b. Set up Calibration: The standards of ~60 common VOC materials (TO15) were run through the analytical instrument at 5 concentration ranges. The percentage of relative variation of all 5 standards must be <30% over the analytical range. c. Quality Control Check Standard: After the above 2 steps were completed, a sample containing 50ng of the following was run: 1,1dichloroethylene, benzene, toluene, chlorobenzene and trichloroethylene. The determined concentrations must fall within 20% of the known values. d. Instrument Check: Before analysis, a method blank was run to verify instrument stability and analytical integrity. Each sample was spiked with an internal standard. Recovery of these internal standards must be between 70% and 130%. Laboratory duplicates were run. All duplicates tested within ±20% of each other. The above procedures were run on the calibration standards only and were not extended to the TIC. The identification by mass spectrometry data was highly confident. The concentration of TIC was based upon the gas chromatography peak associated with the compound and was an estimate only. Aldehyde sampling was collected by passive monitors for the area without electric power and when electric power was available we used a small air pump regulated by a rotometer and absorbent tube. The passive aldehyde monitors use a semi-permeable membrane and a DNPH absorbent. The monitors were exposed for ~24 hours. The absorbate was run by EMSL in Cinnaminson, NJ. Sampling done with the air pump was regulated by the rotometer to control air flow to ~0.5-2.0L/minute. The sampling train was then connected to a dinitrophenylhydrazine (DNPH) coated silica gel tube. This material reacts with aldehydes and ketones and captures them for later analysis (Determination of Toxic Organic Compounds in Ambient Air, EPA 600/4-84-041, U.S. EPA, Research Triangle Park, NC, April 1984). The quality control for TO-11 aldehydes consists of running a basic calibration check and a method blank. Internal standards were also run to confirm analytical precision and accuracy. All of the US EPA TO-15 and TO11 were performed by Columbia Analytical, Inc. (Simi Valley, CA). They are an AIHA accredited facility along with numerous state and federal accreditations. The passive aldehyde monitors were run at the EMSL (Cinnaminson, NJ), a NJ-EPA accredited facility.’