lab4_beam_vibration

advertisement

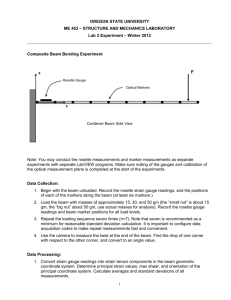

Department of Mechanical Engineering ME 260W - Measurement Techniques Spring 2005 Experiment #4: Beam Vibrations 1. - OBJECTIVES To determine the first three natural frequencies and mode shapes of a cantilever beam To characterize a second-order system by it's damping frequency, and damping coefficient To find the frequency response of a cantilever under sinusoidal excitation 2. EQUIPMENT For this lab, we will use: Power amplifier, CE 2000 Shaker, Model, VTS 100 Strain gage conditioner, P-3500 Digital storage oscilloscope, Tektronix TDS 210 Accelerometer transducer PCB 482A22 Signal conditioner, PCB 488A-01 Computer station with data acquisition A/D board 3. THEORETICAL ANALYSIS A shaker is driven, with displacement y, to displace the fixed end of a cantilever beam and impart harmonic motion in the beam. Mounting two strain gages on the beam as shown in Figure 1 allows the measurement of maximum strain in the beam as the end of the beam oscillates in x direction. With virtual instrumentation, the computer operator can control the motion of the shaker and simultaneously record data from the strain gages. This data can be examined with two different approaches, through determination of the damping ratio and determination of the deflection of the end of the beam. Two metallic resistance type strain gages are used in conjunction with a half Wheatstone bridge as shown in Figure 2. Briefly, the gages are mounted on a specimen and under pre-load conditions; the balance potentiometer is adjusted such that eo is zero. Strain in the specimen elongates the strain gage, altering the electrical resistance in the gage. This change in the gage resistance unbalances the bridge, and results in a voltage at eo. This voltage at eo is proportional to the strain. Using two gages in this configuration results in a doubled bridge output, as compared to using a single gage, and also compensates for temperature effects, and torsional and axial components. As the beam vibrates with harmonic motion, the output from the strain gages is a sine wave with amplitude proportional to the strain and a period inversely proportional to the frequency of the vibrations. 1 Figure 1 Cantilever Beam Setup. Strain gages are mounted on the top and bottom of the beam. The motion of the oscillator is y(t) and the deflection on the end of the beam is x(t). The width of the beam is b, and the thickness is t. Figure 2 Wheatstone Bridge. A half bridge with two strain gages. After the bridge is balanced such that voltage across eo is zero, strain in gages results in voltage across eo. By driving the shaker with a sine wave, the aluminum beam vibrates with simple harmonic motion. Left to vibrate freely, without applied external forces, the beam will vibrate at its natural frequency, n, and its amplitude of the response will decrease with time, as energy in the system is lost. The rate at which this amplitude decreases is known as the logarithmic decrement. The logarithmic decrement,, can be obtained by measuring two displacements separated by n 1 x number of complete cycles and applying: ln o with x o and x n the amplitudes n xn separated by n cycles. From , the damping ratio, , can be found from: . For our system 2 with the displacement of the shaker, y, it can be shown that the deflection, x is approximated by: 2 x y 1 2r 2 1 r 2r 2 2 2 with r . After impacting the beam, and allowing it to vibrate n freely, the measurement will determine the natural frequency of the beam, logarithmic decrement and damping ratio of the beam. Along with the driving displacement, y, this data can be used to determine the deflection, x, at the end of the beam for a given frequency. The deflection in the beam can also be determined by measurements of strain, , in the beam. The maximum deflection of a cantilever beam with a point load on the end of the beam PL3 is: x with P, the load on the beam, L, the length of the beam, E, the modulus of elasticity 3EI for the material, and I, the second moment of area of the beam. The maximum strain in a Mc t cantilever beam is: , ( c with t the thickness of the beam). From these two EI 2 L2 equations, and with M PL we can obtain the deflection, x, with: x . The computer 3c station drives the oscillator at a series of determined frequencies and records the maximum strain at each frequency. With the user input of data from the Beam Data VI and measurements of the beam, along with the acquired driving displacement, the Frequency Data VI calculates the deflection at the end of the beam and the magnitude ratios, (x/y), for each frequency, based on the measured strain and based on the calculated damping ratio. The block diagram for the Frequency Data VI is shown in Figure 4. We now can compare the deflection of the end of the beam based on , n, and , with the deflection based on the measured strain in the beam. The resonant frequencies for a simple cantilever beam is given by C EI n n 2 L4 n = natural frequency in cycles per second E = modulus of elasticity of the material in psi I = moment of inertia in inches L = length in inches = mass per unit length Cn = coefficient for the different resonant modes (C1 = 3.52, C2 = 22.4, C3 = 61.7) 4. EXPERIMENTAL PROCEDURES In this exercise, you are asked to determine the natural frequency, the damping coefficient, phase angle, amplitude response and mode shapes for a cantilever beam. In this experiment, virtual instruments created with LabVIEW software are used to investigate a cantilever beam subject to forced harmonic vibration. The Freevib1 VI determines the harmonic nature of the beam, and the Freqresponse VI drives the beam specified frequencies, and at each frequency, determines the displacement at the end of the beam based on acquired data and harmonic data. 3 In this test, three VI’s are used. The first VI “FreeVib1 VI” is used to determine n, , and . After setting the parameters on the front panel of the VI, the beam is impacted lightly and run the VI. After sampling the signal from the strain gage conditioner for a pre-determined length of time the sampled signal is displayed along with the values for n, , and . The second VI “phaseAngle815 VI” is used to find the phase angle between the response and the input excitations. After setting the parameters on the front panel of the VI. The VI will drive the beam at a series of frequencies and the phase angles are calculated. The third VI “Freqresponse VI” is used to determine the frequency response of the beam. On the front panel of the VI, parameters are set for the input and output signals. The values found by the Frequency Response VI for n, and need to be entered along with the length and half the thickness (c) of the beam. A strain conversion factor needs to be entered. This factor depends on the strain gage(s) and bridge arrangement used. The VI will drive the beam at a series of frequencies and measure the maximum strain and driving displacement at each frequency. Values for the measured strain, driving displacement, calculated deflection based on strain and based on , and magnitude ratios, are written to a specified file. This file can later be opened with a spreadsheet program and examined. Exercise 1: Natural frequency and damping coefficients Measurements a. Mount a strain-gaged beam (beam A) and select a beam length. Zero the strain gage conditioner as follows: Connect the red lead wire from the gage to the P+ terminal on the strain indicator, the white lead wire to the S- terminal and the black lead wire to the D120 terminal. These connections create a quarter bridge circuit by pairing the gage with an internal “dummy” resistor. Make sure that the bridge switch indicates a quarter bridge arrangement. Turn the indicator power switch on and turn the sensitivity knob fully clockwise. Dial the gage factor into the indicator and, with the indicator set for zero strain, adjust the balance knob until the needle points to zero. This process zeroes the indicator at the current state of the beam and no strain on the gage. b. Get free vibration signal by impacting the beam by a light object such as a pen. c. Observe the free oscillations on the oscilloscope and the computer. Measure the rate of decay of free oscillations. The damping ratio can be found by measuring two amplitudes separated by any number of complete cycles. d. Use the logarithmic decrement to determine the amount of damping present in the x beam. ( ln n 2 ). Where xn and xn+1 denote the amplitudes corresponding to times tn x n 1 and tn+1, respectively. Exercise 2: Phase Angle measurements In this section, the PhaseAngle815 VI is used to find the phase difference between the forcing signal and the response signal of the beam. The driving signals and the signal from the strain gage is sampled and saved in the specified file. A strain conversion factor needs to be entered. This factor depends on the strain gage and bridge arrangement 4 Taking Measurements 1. Open the Phase angle815VI. 3. Make sure the SCXI chassis is turned on. 4. Press the Save data button on the VI front panel (option). This stores the data in a file. Set the following parameters on the VI Device:1 Channel 0: ob0!sc1!md2!0 (strain) Channel 1: ob0!sc1!md2!1 (accelerometer) Scan rate: 1000 Number of scans: 1000 Filter Type: band Bass Low cutoff Freq: 30 High cutoff freq: 60 Open Functiongenerator.vi Select sine wave signal Dual cycle 50% Offset: 0 Amplitude 1.0 v Channel: 1 or 0 (check the channel number on the scxi 1302) Run the function generator.vi 5. Start the phaseangle815.VI by pressing the Run button in the top left corner of the VI. Run the VI and measure input voltage and out voltage (can be Vp-p or Vp or Vavg as long as Vin and Vout are consistent. Measure the time difference t between the two waveforms Phase angle = 360 (t/T) a. No filter F (HZ) Vin Vout Vout/vin Vout/vin (db) t (time between the two waves) T ( period) Phase angle=360(t/T) T ( period) Phase angle=360(t/T) Plot Vout/Vin vs f and phase (degrees) vs Frequency (HZ) Repeat for low- and high-pass filters with the theoretical behavior b. Low-pass filter F (HZ) Vin Vout Vout/vin Vout/vin (db) 5 t (time between the two waves) c. High-pass filter F (HZ) Vin Vout Vout/vin Vout/vin (db) t( time between the two waves) T ( period) Phase angle=360(t/T) How well do the measured amplitude responses you have obtained for low- and high-pass filters with the theoretical behavior. Exercise 3: Frequency Response Measurements The freqresponse.Vi is used to determine the frequency response of the beam. The driving signals and the signal from the strain gage is sampled and saved in the specified file. Strain and accelerometer conversion factors need to be entered. These factors depend on the strain gage and bridge arrangement and the accelerometer sensitivity. The VI will drive the beam at a series of frequencies and measure the maximum strain level and driving displacement at each frequency Taking Measurements 1. Open the Freqresponse VI. File path: c:\me260w\Lab6_beamvib lab\freqresponse.vi 2. Make sure the SCXI chassis is turned on. 3. Press the Save data button on the VI front panel (option). This stores the data in an array. Set the following parameters on the VI Shaker settings Device:1 Channel: 0 Level (volts): 0.6 Start frequency (HZ): 4 Stop frequency (HZ): 10 Freq incr: 0.2 ( or .4) Actual frequency: 5 Hz Beam Settings Damping: .007 Natural Frequency: 5 Length: 25 Thickness: 0.125 Acquisition settings Device: 1 Channels 0: ob0!sc1md2!0 (default) Channels 1: ob0!sc1md2!1 (default) scan rate 1000 number of scans 1000 6 strain or acc 1: (select strain) Filter settings Filter type ch 1: band pass Filter type ch 2: band pass strain or acc2 ( select accel) low cut off ch1: 3, high cut off ch 1: 100 low cut off ch2: 3, high cut off ch 2: 100 Run the VI. All data will be written to the specified file (Y/X vs frequency). Y: strain gage output X: accelerometer output Compare the results with the theoretical values Exercise 4: Find the first three mode shapes - - - - Apply a sinusoidal voltage to the shaker, proceeding from low to high frequencies. It may take a short time for the beam to respond to the excitation, particularly at the low frequencies. It takes time to transfer energy to the beam, even at a resonant frequency. Adjust resonance level near resonance, so that both the excitation and the response signals are reasonably sinusoidal. To find a natural frequency, slowly increase the frequency of excitation until a large beam response is observed. At each natural frequency the mode shape is found by locating the position of the nodes. Run a light object as a pencil point along the surface of the beam. When the pencil point ceases to vibrate, it is resting on a node. Repeat the above procedure for three different beam lengths and record the corresponding natural frequencies. Make a log-log plot of the measured natural frequency vs. Beam length showing three lines representing the first, second, and third natural frequencies. Add three lines to the plot, which show the relationship between theoretical natural frequency and beam length. Plot the node location from the fixed end of the cantilever vs. Beam length for the second and third modes. Compare the resonant frequencies of the beam with predicted values. Explain the discrepancy, if any. 7 Figure 1: FreeVib VI – Front Panel 8 Figure 2 – PhaseAngle VI – Front Panel Figure 3: Frequency Response VI -Front Panel 9