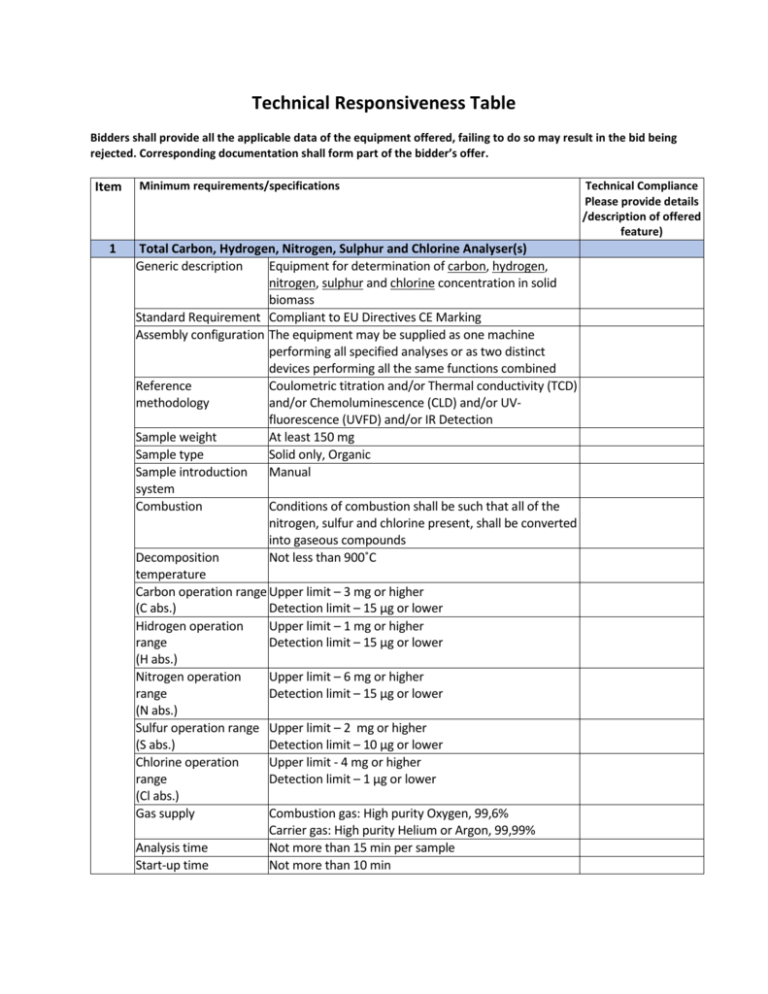

Technical Responsiveness Table

advertisement

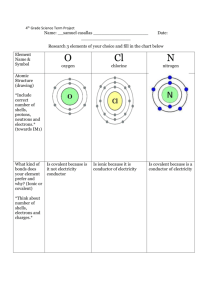

Technical Responsiveness Table Bidders shall provide all the applicable data of the equipment offered, failing to do so may result in the bid being rejected. Corresponding documentation shall form part of the bidder’s offer. Item 1 Minimum requirements/specifications Total Carbon, Hydrogen, Nitrogen, Sulphur and Chlorine Analyser(s) Generic description Equipment for determination of carbon, hydrogen, nitrogen, sulphur and chlorine concentration in solid biomass Standard Requirement Compliant to EU Directives CE Marking Assembly configuration The equipment may be supplied as one machine performing all specified analyses or as two distinct devices performing all the same functions combined Reference Coulometric titration and/or Thermal conductivity (TCD) methodology and/or Chemoluminescence (CLD) and/or UVfluorescence (UVFD) and/or IR Detection Sample weight At least 150 mg Sample type Solid only, Organic Sample introduction Manual system Combustion Conditions of combustion shall be such that all of the nitrogen, sulfur and chlorine present, shall be converted into gaseous compounds Decomposition Not less than 900˚C temperature Carbon operation range Upper limit – 3 mg or higher (C abs.) Detection limit – 15 µg or lower Hidrogen operation Upper limit – 1 mg or higher range Detection limit – 15 µg or lower (H abs.) Nitrogen operation Upper limit – 6 mg or higher range Detection limit – 15 µg or lower (N abs.) Sulfur operation range Upper limit – 2 mg or higher (S abs.) Detection limit – 10 µg or lower Chlorine operation Upper limit - 4 mg or higher range Detection limit – 1 µg or lower (Cl abs.) Gas supply Combustion gas: High purity Oxygen, 99,6% Carrier gas: High purity Helium or Argon, 99,99% Analysis time Not more than 15 min per sample Start-up time Not more than 10 min Technical Compliance Please provide details /description of offered feature) Operating ambient 15-35˚C temperature Metrological approvals Calibration certificate issued by a national metrology body or by a calibration laboratory accredited / recognized in European Union Flow control Software Power consumption Power supply Accessories: Consumables 2 3 Electronic/Software MS Windows based software with data management possibilities, statistical analysis of data etc. Not more than 2.5 kW 230V, 50 Hz A set (kit) of consumables necessary for conducting at least 1.000 sample tests Gas cylinders Oxygen filled cylinder, purity 99,6%, volume 10 m3, pressure 200 bar, with pressure regulator valve Cylinder filled with helium or argon, purity 99,99%, volume 9 m3 pressure 200 bar, with pressure regulator valve Accessories All other accessories required for the installation and operation (connectors, fittings, adapters, tubes, valves, etc.) Documentation Operational manual and documentation in Romanian or Russian detailing the process of periodic replacement of parts. Laboratory cutting mill / grinder Generic description Laboratory cutting mill / grinder for reducing combined samples of solid biofuels to laboratory samples and subsamples Sample amount ≥ 500 g Standard Requirement Compliant to EU Directives CE Marking Material feed size (mm) Not less than 60x60 Final finesse ≤ 1 mm Standard collecting ≥ 3 litres receptacle Supplied accessories Wire-mesh sieve with an aperture size of 1 mm Power consumption Not more than 2,5 kW Voltage supply 230 V, 50 Hz Laboratory Sieving machine Generic description Laboratory Sieving machine for determination of the size distribution of particulate biofuels Standard Requirement Compliant to EU Directives CE Marking Sieving reference EN 15149-1:2010(E) standard EN 15149-2:2010(E) Sieving operation Horizontally oscillating sieves and/or vibrating sieves sorting particles in decreasing size classes by mechanical means 1 1 ≥ 1200 cm2 (EN 15149-1:2010) ≥ 250 cm2 (EN 15149-2:2010) Assembly configuration The equipment may be supplied as one machine performing all specified analyses or as two distinct devices performing the same functions combined Max. batch / feed ≥ 10 kg (EN 15149-1:2010) capacity ≥ 50 g (EN 15149-2:2010) Sieves stacks with Sieves stack (mm) 3.15; 8; 16; 31.5; 45; 63 (EN 15149range of sieves 1:2010) apertures Sieves stack (mm) 0.25; 0.5; 1; 1.4; 2; 2.8; 3.15 (EN 15149-2:2010) Sieves stacks technical ISO 3310-1 requirements ISO 3310-2 standards Timer Digital Accessories Collecting pan Voltage supply 230 V, 50 Hz Effective sieve area