linear fig

advertisement

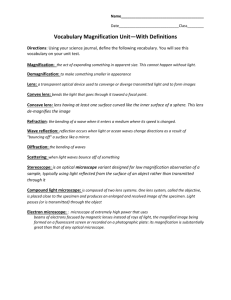

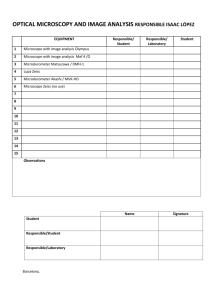

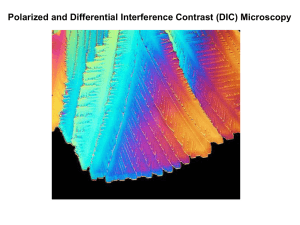

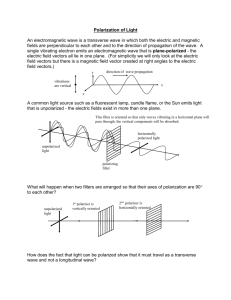

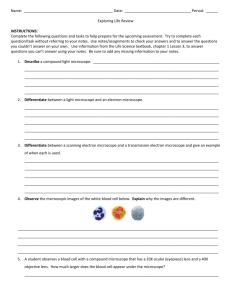

Lab 9: Contact-free measurement of coefficient of thermal expansion using polarized optical microscopy 1. Theory The optical microscope was first used systematically in England by Robert Hooke in 1864 to examine polished sections of opaque materials, notably metals and alloys. By chemical etching he was able to reveal distinct phases in a microstructure. Polarized light is similarly used as a means of rendering microstructures visible in non-cubic metals and polymers. Today, the optical microscope remains a fundamental tool for phase identification1. It magnifies an image by sending a beam of light through a transparent or translucent object, as seen in the schematic diagram of Figure 9.1. Prior to reaching the sample, the condenser lens focuses the light on to the sample, while on the other side of the sample the objective lenses (10X to 2000X) magnify the transmitted light beam, containing the image, to the projector lens Figure 9.1 - Schematic diagram of the optical to be viewed by the observer. microscope. 1.1 Principles of polarized light Ordinary light contains light waves that vibrate in a direction perpendicular to its direction of travel, Figure 9.2. To generate polarized light, ordinary light must pass or be reflected by a polarizing optic. That optic will absorb all directions of vibration except the permitted direction. Thus the light emerging from the interaction is called polarized. Polarized light not only elucidates identifying parameters, it often detects subtle changes. Polarized light exhibits two distinct phenomena: the nature of the incoming light and the internal characteristic of the material. Polarized light enhances contrast based on the difference in refractive indices in at least two directions in a material. For example, a drawn fiber will typically have two refractive indices: one along its length and another 1 http://www.sv.vt.edu/classes/MSE2094_NoteBook/96ClassProj/experimental/optical.html (7/25/204) 1 across its diameter. This anisotropy makes it birefringent (having two refractive indices) and, therefore responsive to polarized light.2 Figure 9.2 - Ordinary vs. polarized light. The amorphous and crystalline regions in a polymer will respond to polarized light through interference. When using the bright field microscope setting with the cross polarizer, the amorphous region of the polymer is optically opaque and will appear dark in the image while the light passing through the crystalline regions will appear white (Figure 9.3). This occurs because the crystalline regions lie along the transmission axis of the light. Figure 9.3 - Bright field image of select crystalline regions transmitting light through polarizer and analyzer appearing light, while amorphous polymer regions are dark. Bradly, R. F., Jr., “Comprehensive Desk Reference of Polymer Characterization and Analysis”, American Chemical Society, Washington, D.C., 2003 2 2 1.2 Coefficient of thermal expansion, CTE Raising the temperature of a material delivers added energy to the atomic bonds of that material, resulting in increased thermal vibrations. Consequently, the increase in distance between adjacent atoms is observed as the linear or volumetric expansion of the material3, Fig. 9.4. Figure 9.4- Increased heating results in longer atomic bond lengths, which we observe as expansion of materials. The linear coefficient of thermal expansion, , is given by the relationship of the change in length divided by the original length per degree temperature, Eq. 1. 𝛼= 𝑑𝑟 𝑟𝑜 𝑥 𝑑𝑇 (1) Where 𝑑𝑟 is the infinitesimal change in length over some temperature range,𝑑𝑇, compared to the original length of the material, 𝑟𝑜 . The typical units of CTE are given in ppm/K since dimensional changes are often measured on the order of m/m/K. For this exercise, we will assume that due to the thin film nature of our samples (ca. 25 m) that the samples will exhibit only linear dilation and therefore only calculate the linear coefficient of thermal expansion. 3 http://www.ami.ac.uk/courses/topics/0197_cte/ (07/25/2014) 3 2. Materials Each team will receive a piece of Ultem® polyetherimide (PEI) film approximately 1cm x 1cm x 25 m. We will be using an Olympus optical microscope, Fig. 9.4, mounted with two polarizers, one below and one above the sample. The sample will be heated from room temperature to 100°C per the schedule in Table 9.1. The schedule will be programmed using a Linkam TMS 94 temperature controller, Fig. 9.5. 1 6 7 8 2 3 4 5 9 10 11 12 Figure 9.4: Key components of the Olympus Optical Microscope. (1) eyepiece; (2) objective lens; (3) translational thermal stage; (4) polarizer; (5) iris/shutter; (6) digital camera; (7) objective device selection slider; (8) analyzer (2nd polarizer); (9) power switch; (10) coarse focus adjustment; (11) fine focus adjustment; (12) light intensity adjustment. Table 9.1 – Heating schedule for PEI film using Linkam TMS 94 controller. Heating rate 10°C/min. Temp. Hold Temp. Hold Room temp. (~21°C) X 60°C 7 min 30°C 7 min 70°C 7 min 40°C 7 min 80°C 7 min 50°C 7 min 100°C 7 min 4 Figure 9.5: Thermal stage temperature controller. 3. Experimental Procedure (1) Click on “Pax it” icon click on the computer desktop to activate imaging program, and button on the tool bar to turn on the camera (preview window will pop up). (2) Turn on the microscope using the power switch 9. Put the PEI film slide on the temperature-controlled heating stage. (3) Using the 5X objective lens (with red stripe on the surface), adjust the light intensity to get proper illumination by turning intensity knob (12) and iris (5). Adjust focus to get a clear image. Keep stage cover on during heating. Be careful when focusing, to not touch the objective lens to the stage. (4) Increase the magnification of the objective and refocus until you have reached the 50x lens (white stripe). (5) Rotate the switch on the analyzer 8 to get an image with minimum intensity (i.e., the polarizer and analyzer are crossed to each other!). The crystalline regions can identified as specs of white light being transmitted. Collect your room temperature image. (6) Turn on the temperature controller by pressing Start button. -Press Rate to set the heating rate at 10°C/min, then press Enter. 5 -Press Time to set the hold time to 7 min, then press Enter. -Press the Limit to set the upper temperature at 30°Cthen press Enter. Repeat for temperatures at 40°C, 50°C…100°C. (7) Collect images of the PEI polymer film at room temperature, 30°C, 40°C, 50°C, 60°C, 70°C, 80°C and 100°C by clicking on Camera file capture button in the software. (Note the slide number and the corresponding temperature) 4. Assignments: 4.1 Explain the reason for conducting the exercise under polarized light; identify advantages of this technique over the more traditional CTE measurement method of thermal mechanical analysis (TMA). 4.2 Using MS Paint, or comparable software, identify a set of pixel “origin” coordinates to be used in each of your images; i.e. (0,0). Identify 5 crystalline regions in your room temperature image, which can also be easily identified in your subsequent temperature ramp images. Using the image collected at each temperature, label your crystalline regions with clear locations and identifiers (a,b,c…1,2,3…) similar to figure 9.3. Create a table identifying each crystalline region along with its x and y coordinates for every temperature data collected. 4.3 Calculate the distance, r, each of the crystalline regions travelled; use the Pythagorean relationship in Cartesian coordinates. Also report the conversion of the distance in pixels to micrometers using the information below. 4.4 Calculate the average linear coefficient of thermal expansion of PEI film, at each temperature, in units of µm/m/°C. Are the average values over the temperature range up to 100°C consistent? Justify your response by showing the standard deviation of the various CTE values calculated at the various temperatures. Note: The distance conversion using 50X objective lens is 100 m/484 pixels. 6