Sealing, painting, coating and cleaning ACM insitu

advertisement

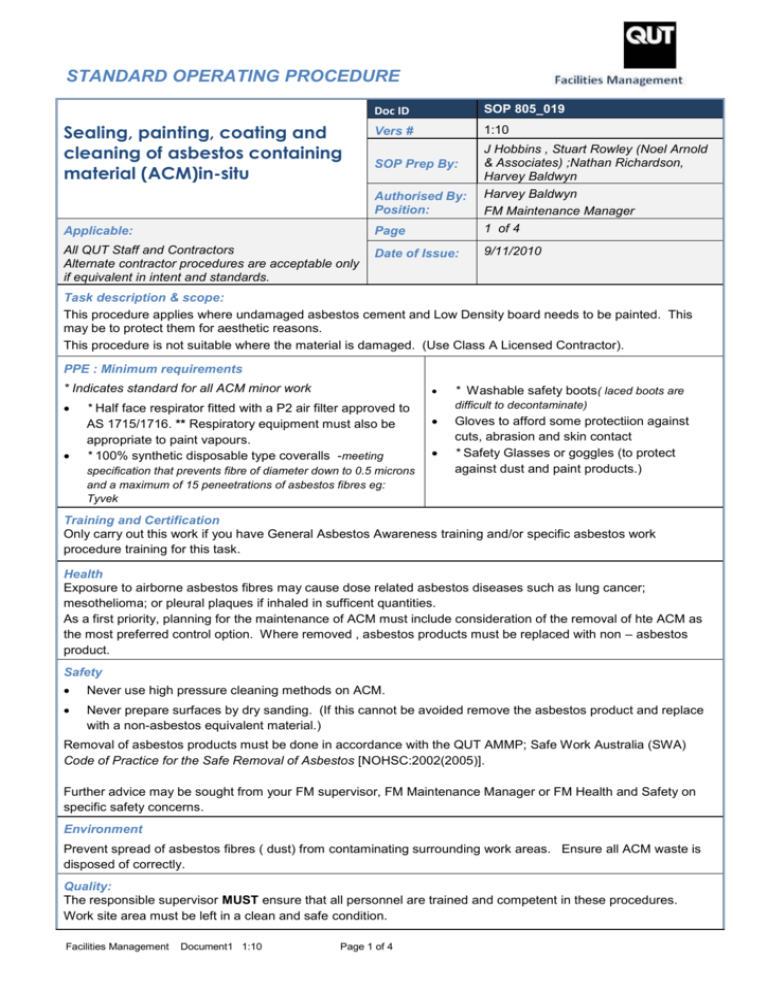

STANDARD OPERATING PROCEDURE Doc ID SOP 805_019 Vers # 1:10 SOP Prep By: J Hobbins , Stuart Rowley (Noel Arnold & Associates) ;Nathan Richardson, Harvey Baldwyn Authorised By: Position: Harvey Baldwyn FM Maintenance Manager Applicable: Page 1 of 4 All QUT Staff and Contractors Alternate contractor procedures are acceptable only if equivalent in intent and standards. Date of Issue: 9/11/2010 Sealing, painting, coating and cleaning of asbestos containing material (ACM)in-situ Task description & scope: This procedure applies where undamaged asbestos cement and Low Density board needs to be painted. This may be to protect them for aesthetic reasons. This procedure is not suitable where the material is damaged. (Use Class A Licensed Contractor). PPE : Minimum requirements * Indicates standard for all ACM minor work * Half face respirator fitted with a P2 air filter approved to AS 1715/1716. ** Respiratory equipment must also be appropriate to paint vapours. * 100% synthetic disposable type coveralls -meeting specification that prevents fibre of diameter down to 0.5 microns and a maximum of 15 peneetrations of asbestos fibres eg: Tyvek * Washable safety boots( laced boots are difficult to decontaminate) Gloves to afford some protectiion against cuts, abrasion and skin contact * Safety Glasses or goggles (to protect against dust and paint products.) Training and Certification Only carry out this work if you have General Asbestos Awareness training and/or specific asbestos work procedure training for this task. Health Exposure to airborne asbestos fibres may cause dose related asbestos diseases such as lung cancer; mesothelioma; or pleural plaques if inhaled in sufficent quantities. As a first priority, planning for the maintenance of ACM must include consideration of the removal of hte ACM as the most preferred control option. Where removed , asbestos products must be replaced with non – asbestos product. Safety Never use high pressure cleaning methods on ACM. Never prepare surfaces by dry sanding. (If this cannot be avoided remove the asbestos product and replace with a non-asbestos equivalent material.) Removal of asbestos products must be done in accordance with the QUT AMMP; Safe Work Australia (SWA) Code of Practice for the Safe Removal of Asbestos [NOHSC:2002(2005)]. Further advice may be sought from your FM supervisor, FM Maintenance Manager or FM Health and Safety on specific safety concerns. Environment Prevent spread of asbestos fibres ( dust) from contaminating surrounding work areas. Ensure all ACM waste is disposed of correctly. Quality: The responsible supervisor MUST ensure that all personnel are trained and competent in these procedures. Work site area must be left in a clean and safe condition. Facilities Management Document1 1:10 Page 1 of 4 STANDARD OPERATING PROCEDURE Equipment required in addition to normal tools or materials 200 micron polythene sheeting & duct tape; Warning tape , barricades and safety signage PVA glue Paint conforming to the job specification. E.g. Fire resistant if required Type H Vacuum Cleaner Low pressure paint spray bottle or roller/brush Bucket of water, rags and wet wipes Suitable asbestos waste container E.g Labelled 200 micron asbestos waste bag Bucket of water, rags and wet wipes Suitable asbestos waste container (eg- labelled 200 micron asbestos waste bag Appropriate task lighting Referenced Documents QUT Asbestos Materials Management Plan PLN805_010; Qld WH & S Regulations; Code of Practice for the Safe Removal of Asbestos [ NOHSC:2002(2005)]; Code Of Practice for management and control of asbestos in workplaces [NOHSC:2018 (2005)] Facilities Management Document1 1:10 Page 2 of 4 STANDARD OPERATING PROCEDURE Sealing, painting, coating and cleaning of ACM in-situ Step Who 1.Prepare work area 2. Sealing or Painting Action QUT Staff or contractor - QUT Staff/ Contractor Document1 1:10 Before starting check there is no damage - This work may be carried out at height, if so, the appropriate precautions MUST be taken - Ensure all necessary electrical isolations have been made - Carry out the work with the minimum of people present - Restrict access to work area, E.g close door and/or use warning tape or signage - Use Plastic sheeting, secured with duct tape, to cover any surface within the segregated area which could become contaminated. (This also helps prevent run off from wet sanding methods) - Ensure there is adequate lighting. - Never prepare surfaces by dry sanding methods. (Wet sanding may be used provided all run off is captured and filtered where possible) - Repair any minor damage – (E.g Use damp/wet rags to remove small bits of loose material) - If dust needs to be removed, use a Type-H Vacuum cleaner or rags - Apply building fillers with a non abrasive tool where required and allow to dry.. - Seal surfaces with PVA solution (This acts as an encapsulant and key) - Preferably use low pressure spray bottle to apply paint - Spray using a sweeping motion - Do not focus spray nozzle on one area as this may cause further abrade or damage - Alternatively apply a brush/roller lightly to avoid abrasion or other damage - Dispose of brush/roller as asbestos waste as they may contain dust and fibres - Use wet rags to clean the equipment - Use wet rags to clean the segregated asbestos work area or Type H Vacuum cleaner - Place debris, used rags, plastic sheeting and other waste into asbestos waste container QUT Staff/ Contractor 3. Clean up Facilities Management - Page 3 of 4 STANDARD OPERATING PROCEDURE Sealing, painting, coating and cleaning of ACM in-situ Step Who 4. Personal De-contamination Document1 1:10 - Where available, use a H-Type vacuum cleaner to clean your overalls or clothes. - Otherwise use a damp-rag (use patting action) as rubbing can generate airborne fibres - Where two or more workers are involved they can clean each other (buddy cleaning) - Remove disposable overalls by turning inside out & place in suitable asbestos waste container - Disposable respirators can then be removed and placed in a suitable asbestos waste container - Dispose of all waste, including all water, as asbestos waste. - Visually inspect the area to ensure it has been properly cleaned - Clearance air sampling is not normally required QUT Staff/ Contractor QUT Staff/ Contractor 6. Site Clearance Facilities Management Action Page 4 of 4