File

advertisement

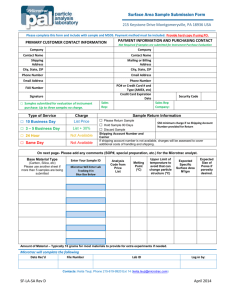

Design Project Justin Jones, Diego Saavedra, Drew Holt, Samantha Daniell Objective The objective of this assignment was to create an eco-friendly packaging system that would protect an egg from breaking after falling two stories. A 10 cm x 10 cm box was to be constructed out of wood, insulated with the selected biodegradable packaging, sealed with an egg inside, and then dropped from the top floor of Corley. The performance of the packaging system would then be determined by the condition of the dropped egg. Methods/Design The first aspect of the project to approach was the box. Our box was constructed out of ¼ inch sheets of plywood cut into 10 cm squares. Wood glue was applied to the edges of the pieces to keep it secure. The quarter inch thickness of the wood caused the size of the box to be larger than required. A tape measure was used to mark the excess wood and a handsaw cut the left over length; this process was repeated three times to create multiple boxes for testing. Next we had to design the packaging for the egg. Several ideas were considered during the initial brainstorming, including old (100% cotton) t-shirts, banana peels, pine straw, and sponges. Each idea had its pros and cons, and eventually we decided to choose and test pine straw. The pine straw was packed tightly into the bottom of the box, an egg placed in the middle, and more pine straw packed around and above the egg to ensure there was little room for movement during the fall, as shown in the figure above. Our hope was that the box would absorb the majority of the impact and that the pine straw would keep the egg from rising during the fall and hitting the bottom of the box during impact. Our first and second attempts with pine straw were unsuccessful, the eggs did not survive the fall. After seeing just how fragile our eggs were compared to the force of impact from two stories, our next approach was a combination of two of our early brainstorms: old tshirts and pine straw. Two strips of an old 100% cotton t-shirt were wrapped around the egg, which was then packed into the box with pine straw, as shown in the figures above. Again the pine straw served as a stabilizer, minimizing the movement of the egg during the fall and impact. The cotton fabric served as extra shock absorption. This design was successful in protecting the egg from the fall. Life Cycle Analysis It is common for companies shipping eggs, like Eggland’s Best, to use a type of polystyrene foam to protect the eggs during shipping. Eggland’s Best boasts the sustainability and eco-friendly construction of these shipping systems, proposing that this foam can be recycled into a multitude of other items, often used again for shipping. However, regardless of how many times it can be used, foam eventually ends up buried beneath the earth in a landfill. Our shipping design offers a more eco-friendly approach. According to the Environmental Protection Agency, approximately 14.3 million tons of textile waste was produced in 2012. This waste could be repurposed by shipping companies, particularly companies like Eggland’s Best who ship fragile cargo like eggs. This textile waste can serve as shock absorption for eggs during shipping. Once the fabrics have become too worn to use for shipping, they can be sent to an incinerator instead of a landfill, or can be composted if they are 100% cotton. The second component of our shipping design, pine straw, is organic matter and decomposes naturally without taking up space in a landfill. In addition, it can be repurposed in agricultural areas to protect plants from weeds and to aid in the overall beauty of a landscape design, or be used in a compost that can be later utilized as fertilizer. Cost Analysis Our group had our shipping system materials on hand and did not have to purchase anything for the project. However, a large shipping company would not be so fortunate. Textile waste can be donated to or purchased by the shipping company from the textile factories themselves or through companies like Leigh, who salvage and repurpose textile waste to avoid the common landfill fate. Leigh even has opportunities to trade for textile waste. If a company like Leigh were utilized, textile waste could be repurposed for the shipping of fragile cargo such as eggs at little to no cost for the shipper. Pine straw is sold commercially for about $60 per 100 square feet. If each egg were allowed a 10 cm x 10 cm space filled with pine straw, $60 would ship around 930 eggs. A typical egg shell foam that can ship 25 eggs costs $2.75, which means that shipping the same number of eggs would cost a company about $100, $40 more than our pine straw/textile alternative. Appendix Box CAD drawing Date April 7th Location Student Center Labor Brainstormed (all members) April 11th Justin’s Built box (Drew and Justin) April 14th Corley Tested (all members) April 15th Student Center Brainstormed (all members) April 17th Corley Final testing (all members) April 19th Library April 20th Library Researched for report (Samantha and Diego) Wrote report (Samantha) April 21st Library Created presentation (Diego) April 23rd Library Practiced presentation (all members) Sources: http://www.egglandsbest.com/about-us/sustainability.aspx http://www.epa.gov/epawaste/conserve/materials/textiles.htm http://www.leighfibers.com/textile_salvage/ http://shop.pinestraw.com/collections/pine-straw-home-delivered http://southernfarmhatchery.com/Egg-Shipping-Foam.php