CHEN5110 Pulp and Paper Engineering

advertisement

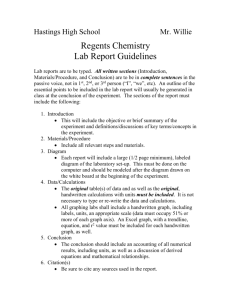

CHEN 5110 – PULP AND PAPER ENGINEERING (3) Technical Elective Course 2009-2010 Catalog Data Lec (3). Chemical and engineering principles in the manufacturing of pulp and paper. Prerequisites Pr: CHEN 3090, CHEN 3620, CHEN 3700; P/C: CHEN 4450 Schedule Three one-hour class session per week. Course Objectives Study of the chemical and engineering principles involved in the manufacture of pulp and paper. Process engineering calculations as applicable to pulp and paper systems. . Textbooks Biermann, Handbook of Pulping and Papermaking, 2e, 1996, 9780120973620, Academic Press Topics Covered 1. Wood structure, chemical components, calculations (1 week) 2. Wood yard and wood handling, process calculations (1 week) 3. Kraft pulping process, cooking liquor, batch flow diagrams, process variables, calculations (2 weeks) 4. Alkaline pulping kinetics, control, digester operation, blow heat recovery, continuous digester, calculations (3 weeks) 5. Brownstock washing and multiple effect evaporators, calculations (2 weeks) 6. Chemical recovery, furnace, causticizing and lime kiln, calculations (2 weeks) 7. Stock preparation, paper machine wet end, approach flow, screening and cleaning, water use and reuse, fiber recovery, calculations (2 weeks) 8. Secondary Fiber Operations (1 week) 9. Pressing and drying, process calculations (1 week) Course Outcomes Upon successful completion of this course, students should be able to: 1. Perform a material balance on a typical wood yard. 2. Perform material and energy balances for a kraft batch digester/blow tank system. Calculate steam requirements, flash steam production and cold blow black liquor requirements. 3. Calculate the H-factor given digester operating parameter information. 4. Perform material and energy balances for a Kamyr hydraulic digester. Calculate various steam requirements, black liquor flows and %solids in the liquor to evaporator, flash steam produced and all process flows around the digester. 5. Perform liquor and dissolved solid balances on vacuum drum washer and calculate washer loss. 6. Perform material balances on a Tomlinson furnace, calculate air supplied by an F.D. fan and the I.D. fan load. 7. Perform material balances on the causticizing section; use a given causticizing efficiency to calculate slaker flow, white liquor clarifier underflow and overflow streams. 8. Perform material balances on a lime kiln. 9. Calculate furnish flows in the stock preparation/approach flow section of a paper machine. 10. Perform material balances on a Fourdrinier machine. 11. Calculate single pass retention and overall retention of fillers and fibers. 12. Perform dryer material and energy balances. Calculate drying rates and thermal efficiencies. Contribution of Course to Meeting ABET Criteria 5 (Curriculum) Math and Basic Sciences 0 Credits Program Outcome Level of Coverage A S Engineering Topics 3 Credits General Education 0 Credits Relationship of Course to Program Outcomes (PO’s) B C D E F G1 G2 H S R Date of Preparation and Person(s) Preparing This Description February 6, 2010: William Josephson I J K