Solutions for Pulp and Paper Production

advertisement

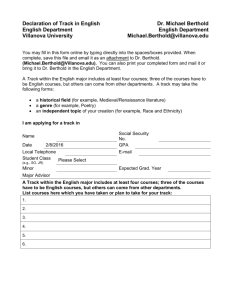

Solutions for Pulp and Paper Production Mass flow, Density Measurement, Level and Moisture Measurement detec t and identify Applications in the Pulp and Paper Industry Processing and Production. Berthold Technologies‘ measurement systems are used in pulp mills all over the world to monitor critical processes and to improve production efficiency. As technology leader in radiometric and microwave technology we bring benefits to the pulp and paper industry by providing highly accurate, highly repeatable online measurements – the base for major cost savings, plant availability and reliable process management. We are renowned for our ability to provide both a wide range of standard products as well as tailor-made measurement solutions, thus perfectly adapting to our customers‘ needs in terms of geometry, measurement performance and economic requirements. The huge number of measuring systems in operation worldwide are the best proof for the high quality of Berthold products and services. Non-contact perfect! All measurement solutions are noncontacting and non-intrusive. The advantage: No exposure to process media and therefore not affected by acidic, caustic, abrasive or sticky conditions Measuring the mass flow of wood chips or bark Free of wear and maintenance Measuring the moisture of wood chips Measuring the filling level in the pulp digester Measuring lime mud density Easy to install on existing pipes, vessels or conveyor systems Lowest cost of ownership 2 | 3 Measuring liquor density Measuringpulp stock level in the standpipe of the MC pump Measuring mass flow of recycled paper detec t and identify Typical measurement arrangement on a screw conveyor. Radiometric belt weigher measures the mass flow non contacting. The results are stable over many years and frequent re-calibrations are not needed. 4 | 5 Measuring the mass flow of wood chips or bark In order to optimise boiler operation, the amount of fibres does not need to be re-calibrated and provides reliable that are fed into the tank needs to be controlled. By using results during the whole time of operation. The system a radiometric belt weigher the mass flow of wood chips can be installed on belt conveyors, on drag chain conve- or bark can be measured by means of a non contacting yors, on screw conveyors and on any other conveyor types. technology. The main advantage compared to conventio- Subsequent installations on existing boiler feeding lines nal weighing systems is that the radiometric belt weigher are easily feasible. Application Profile Measurement task Mass flow of wood chips or bark Location Boiler feeding line Berthold Solution Radiometric belt weigher, e.g. LB 442 Customer Benefit Online, real-time process information Optimised boiler operation Ideal balancing of boiler fedstock Characteristics Non contacting measurement, irradiating the wood chips or bark by means of gamma radiation High repeatability, no need for frequent re-calibrations Maintenance free Virtually no operation costs Accuracy < 3 % Excellent measurement stability Not affected by varying belt tension, vibrations or bumps detec t and identify Online moisture system installed on the wood chips conveyor. 6 | 7 Measuring the wood chips moisture The determination of dry fibrous material is important content online. With an emitting antenna below and a to keep the boiler efficiency constant. Especially in the receiving antenna above the belt, the microwave pene- summer time, when the wood chip stockpiles are moiste- trates the whole material cross-section leading to high ned the water concentration can vary drastically. The representative, real-time information. An additional radi- Micro-Polar system based on non contacting microwave ometric system can be used to compensate for variations transmission technology is used to measure the moisture in bulk density and load. Application Profile Measurement task Moisture content in wood chips Location Boiler feeding line Berthold Solution Microwave transmission system, e.g. Micro-Polar LB 568 Customer Benefit Improved boiler efficiency Optimised boiler operation through in-situ information on water content Easy retrofit of existing lines without modification Reliable on-line control of cooking process Characteristics Non contacting measurement Easy to install on existing conveyor belts Highly representative through transmission technology High measurement repeatability State-of-the-art Microwave Transmission technology, penetrating the whole material cross-section detec t and identify 8 | 9 Measuring level in the pulp digester The wood chips and chemicals are cooked in the digester outside of the digester is not affected by the severe con- in order to extract cellulose. The conditions in the digester ditions prevailing inside and allows for reliable control of are of high temperature and caustic nature. To control the the digester filling. Thus the digester can be loaded with as filling level in the digester a radiometric level measurement much raw material as possible. A high level switch provides is used. The non-contacting measurement installed on the additional process safety if needed. Application Profile Measurement task Level measurement of digester feedstock / High level alarm Location Pulp digester, cooking process Berthold Solution Radiometric level measurement and level switch Customer Benefit Optimised utilisation of digester capacity Increased process efficiency high reliability of control over the cooking process Improved plant availability Characteristics Non contacting level measurement using radiometric technology Detectors and sources are mounted on the outside of the tank Highly accurate, repeatable measurement Not affected by the high temperature and caustic conditions inside the digester Maintenance free SIL2 / SIL3 certification for continuous level measurement and level switch Typical arrangement of a radiometric system for noncontacting, non-intrusive density measurements. detec t and identify Measuring lime mud density In the regeneration of pulping chemicals, lime mud is application, because it doesn’t contact the suspension and formed as a by-product. Several process steps follow to doesn’t wear out. As a simple clamp-on solution it is easy convert the suspension back into calcium oxide (“lime”). to install without process downtime. The high accuracy During these processes it is important to have real-time and repeatability of the measurement helps to optimise information on the solid content and the density of the the recovery process, while the effort to maintain the sys- lime mud. A radiometric system is ideal for this type of tem is neglectable. Application Profile Measurement task Lime mud – density and solids content measurement Location Re-causticisation process Berthold Solution Radiometric density and concentration measurement Customer Benefit Real-time information on density and solids content Improved control over lime mud processing Optimised use of recovery chemicals like flocculants lead to cost savings Lowest operation costs Characteristics Non contacting radiometric density measurement Easy to install, clamp-on system Long system life, no wear and tear Highly repeatable measurement No need for recalibrations Maintenance free operation Typical arrangement of a radiometric system for noncontacting, non-intrusive density measurements. 1 0 | 11 Measuring liquor density Recovering and regenerating the pulping chemicals and systems, which are clamped on to the pipe and provide burning off organic material dissolved from wood are highly repeatable readings. The measurement is carried critical steps in the pulp mill. An accurate, repeatable out non-contacting and is therefore not affected by the on-line density measurement is absolutely necessary to high temperature and the chemical properties of the properly operate this phase of the process. Black liquor liquor. Subsequent installation on existing lines is easily and green liquor densities are measured by radiometric feasible without process downtime. Application Profile Measurement task Green liquor and black liquor density measurement Location Re-causticisation process Berthold Solution Radiometric density and concentration measurement Customer Benefit On-line, real-time information on liquor properties Optimised liquor regeneration process Increased plant availability Virtually no operating and maintenance costs Easy retrofit without process downtime Characteristics Non contacting radiometric density measurement No flow disturbance, no wear and tear Easy to install, clamp-on system Highly repeatable measurement with the need for recalibration Not affected by the hostile chemical properties or temperature of the liquor Maintenance free operation detec t and identify 12 | 13 Measuring level on the standpipe of the MC pump Maintaining the level of pulp stock in the standpipe of the and causing high maintenance costs. Consequently a MC pump is of high importance. If the pulp level in the radiometric level measurement is used to control the pulp standpipe falls below a certain value it can cause cavitati- level in the standpipe – non contacting and non intrusive. on of the pump. Overflow and back-ups into the pulp sys- The measurement is highly accurate and even quick level tem needs to be avoided. The traditional instrumentation, changes can be monitored reliably. As a result, the avai- using DP cells, and capacitance probes has proven to be lability of the pump and the efficiency can be improved. ineffective for this application, leading to false readings Application Profile Measurement task Level measurement of pulp stock in the MC pump standpipe Location MC pump Berthold Solution Radiometric level measurement Customer Benefit Increased process safety Prevents cavitation Prevents from overfilling Improved MC pump performance Characteristics Non contacting, non-intrusive level measurement Maintenance-free Detectors and sources are mounted on the outside of the standpipe Highly repeatable Quick measurement response SIL2 / SIL3 certification for continuous level measurement and level switch Radiometric system installed on a MC pump standpipe is a long-term solution to reliably measure the pulp level. detec t and identify Measuring mass flow of recycled paper The processing of recycled paper involves cooking of the Installations are possible on all conveyor types, e.g. belt paper to recover lignin. In order to control the amount conveyors, drag chain conveyors, bucket conveyors or of paper that enters the cooking process, a radiometric screw conveyors. The measurement is highly accurate belt weigher is used. This measures the bulk flow non- and repeatable, so that there is no need for re-calibrations. contacting and non-intrusive, without any moving parts. Application Profile Measurement task Mass flow of recycled paper Location Boiler feeding line Berthold Solution Radiometric belt weigher, e.g. LB 442 Customer Benefit Online, real-time process information Optimised boiler operation Ideal balancing of boiler fedstock Characteristics Non contacting measurement, irradiating the wood chips by means of gamma radiation High repeatability, no need for frequent re-calibrations Maintenance-free Virtually no operating costs Accuracy < 3% 1 4 | 15 detec t and identify Berthold Technologies offers the most sensitive detec- remains unchanged. This is a major advantage especially tors on the market, thus allowing for highly accurate and when aged sources become less effective, the high-sensi- repeatable measurements using source activities which are tive detectors from Berthold Technologies can still do the several factors smaller than conventional systems. Depen- measurement. In this way the source life can be almost ding on the application the source activity can be reduced always increased by 10 or more years, saving costs and by as much as 80% while the measurement performance improving the utilisation of radioactive sources. BERTHOLD TECHNOLOGIES GmbH & Co. KG Calmbacher Straße 22 · 75323 Bad Wildbad · Germany Phone +49 (0)7081 177-0 · Fax +49 (0)7081 177-100 E-mail: info@berthold.com · www.berthold.com detec t and identify Industry Brochure Pulp & Paper 06-2016 - Id.-Nr. DC00433PR2 , Rev. 00 Retrofit Solutions