2011-SDSR001 - Sustainable Food Trade Association

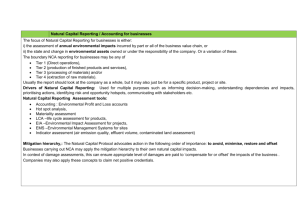

advertisement

So Delicious Dairy Free FTSLA Annual Sustainability Report 2012 Covers activities from October 2011 – September 2012) Hansel New November 14, 2012 Author of the Report and Data Collection Process REQUIRED Contact info (phone/email): Hansel New 541-338-9400 x3452 hnew@sodeliciousdairyfree.com Position in the company: Sustainability Manager Provide information on how the company collected and verified the information/data and what department functions were involved? Data was collected from official company records including HR files, accounting documents, and directly from on-site meters, utility bills, and Accounts Receivable files. Background Information REQUIRED Turtle Mountain was founded in 1987 by Mark Brawerman. We aspire to be the premier dairy-free food and beverage company known for the quality and integrity of our brands, products, people and practices. We will drive our categories through all-natural, innovative and differentiated products that exceed our consumers' taste and health expectations. Our passions are to help our consumers and our planet live better longer. We produce and distribute products primarily to U.S. and Canadian markets and employ approximately 150 people. As a natural foods company with exclusively dairy-free offerings, we pride ourselves on offering a wide range of organic and made with organic products, and all of our ingredients are from non-GMO sources. Our definition of sustainability is delivering quality dairy-free foods at a competitive price, while systematically reducing our environmental impact and building a socially responsible company. In our approach we recognize that true sustainability is an ongoing journey and commit ourselves to continuous improvement in all aspects of our business. 2 We offer the broadest selection of dairy free solutions to our consumers and are thrilled to have this distinction. Our diverse range of coconut, almond, and soy based products include non-dairy frozen dessert pints, quarts, novelties, and beverages, cultured products and creamers. All of our frozen desserts are made right here in Springfield, Oregon. Additional manufacturing for our refrigerated product lines is handled through a series of co-packers nationwide. All finished products are manufactured in the United States. We source our primary ingredients like organic coconuts, organic dehydrated cane juice, organic cocoa, etc. from our global supply chain, while purchasing several variegates, fruit preps and other fine ingredients from the United States. Turtle Mountain’s headquarters is Springfield, Oregon, with additional offices and manufacturing facilities located in the Eugene/Springfield, Oregon area. More information on our business philosophy, our products, and much more can be found on our website www.sodeliciousdairyfree.com. Data for this report has been collected and maintained using internal tracking and metrics which began when our sustainability program was established in January 2011. Information is generally not available from earlier than this time period. Annual Reporting Commitment On June 21, 2010 –Turtle Mountain, LLC became a member of the Sustainable Food Trade Association (SFTA). This organization provides business in the organic food trade with guidelines and recommendations for how to embody sustainability in their own operations. The SFTA spent two years compiling input from organic growers, distributors, processors, retailers and certifiers to create an 11-point action plan titled “Declaration of Sustainability in the Organic Food Trade.” Companies that sign the pledge commit to continuous improvement and transparency around practices in key areas. On that date, Turtle Mountain, LLC signed on to the Declaration committing to reporting annually our performance in the 11-action categories that include organic & land use, distribution & sourcing, energy, climate change & emissions, water use & quality, solid waste reduction, packaging & marketing materials, labor, animal care, sustainability education, and governance & community engagement. Each year, we will strive for continuous progressive improvement and to practice transparency in annually auditing our performance and selecting reporting metrics that are relevant to our business. This report is a compilation of information we have collected and intend to submit to the FTSLA to qualify for ongoing membership in the association. 3 1. ORGANIC AND LAND USE PRACTICES Narrative Description We support sustainable agriculture to help minimize our impact on the environment. All organic ingredients are certified organically grown and processed in accordance with USDA standards. We use Organic Certifiers to certify the organic content of our product lines. Two of our most widely used ingredients – dehydrated cane juice and coconut – are certified organic ingredients and support sustainable agriculture in several countries including Brazil, the Philippines, and Sri Lanka. ORGANIC AND LAND USE METRICS AND INDICATORS POLICY AND GUIDELINES, PRACTICES Policy: Does your company have a policy or general guidelines in place regarding production or purchasing of organics? If so, state the policy and/or provide document or URL. Include name of organic certifier. (GRI 4.8) CORE CORE Member company response: We support sustainable agriculture to help minimize our impact on the environment. All organic ingredients are certified organically grown and processed in accordance with USDA standards. We use Organic Certifiers to certify the organic content of our product lines. Practices & Guidelines: Provide a narrative describing your organic practices and efforts related to biodiversity, forests and native ecosystems, including progress made since your last report, if applicable, and descriptive goals (GRI EN 11, EN 12) Member company response: Purchasing organic ingredients is viewed as the primary method of meeting our commitment to sustainable agriculture and certified Organic is always given preferential treatment when considering new products/ingredients. We are one of North America’s largest purchasers of organic coconuts from SE Asia, and we support the Green Cane Project in Brazil through our organic sugar purchases. ORGANIC PRODUCTION AND PURCHASING Total Annual Organic Products/Ingredients Purchased or Sold in Pounds - % of total purchases by weight that are certified organic CORE All businesses except farms should report purchases, farms should report sales. Use dollars if pounds cannot be derived. Use sales if purchasing cannot be derived. Member Company Response: 65.9% certified organic ingredients 4 Certified Organic Acres in past year - % of total acres grown Member Company Response: N/A Acres in Organic Conversion in past year - % change year over year Member Company Response: N/A Total Annual Transitional Product/Ingredients Purchased or Sold in Pounds - % of total purchases by weight that are transitional All businesses except farms should report purchases, farms should report sales. Use dollars if pounds cannot be derived. Use sales if purchasing cannot be derived. Member Company Response: We do not track ingredients that may be transitioning to organic, as we feel this is a relative value that has no relevancy for purchasing. ORGANIC OTHER Provide narrative describing farming practices for all other agriculturally derived materials involved in your operation including bio based fuels and packaging, company meals, fiber, and other products. Member Company Response: Company does not track other organic purchases. Organic Materials in past year - % of organic in other agriculturally derived materials used (e.g., packaging fiber-based materials, etc). Member Company Response: No data available ORGANIC BENEFITS Provide any measured benefits of your organic practices (activities or purchasing), such as: 1. Soil health testing/measurement (soil organic matter, soil carbon, ph, available water holding, water percolation/infiltration, erosion) 2. Air quality 3. Water quality 5 4. Improved biodiversity on or near farms 5. Avoided synthetic inputs: type and amount 6. Climate benefits: soil carbon sequestration, avoided emissions (direct activities/processes and inputs) 7. Embedded energy savings (inputs) 8. Non-renewable resource savings (e.g., not using petroleum-based inputs) Member Company Response: We are keenly interested in quantifying the benefits of organic agriculture. At the current time, while we have much information on the general benefits of organic agriculture in key commodity crops such as cane sugar, coconuts and soybeans, we have not developed the capability to quantify the benefits of our specific volumes of these ingredients to specific environmental benefits. BIODIVERSITY, NATIVE ECOSYSTEMS, SUSTAINABLE FORESTRY Provide narrative describing how you protect and enhance biodiversity, native ecosystems and forests (native/old growth and secondary) in relation to agriculture and other key business activities/purchases (GRI EN 11-14) Member Company Response: No data available LAND USE CERTIFICATIONS Certifications: List certifications related to land use and agriculture practices, and acreage or % of purchases covered (e.g., biodynamic, Forest Stewardship Council, Salmon Safe, Rainforest Alliance) (GRI EN 11-14) Member Company Response: Non-GMO Project Verified – 100% ingredients Certified Organic – 65.9% ingredients GOALS Please state any measureable improvement goals for Organic and Land Use practices. CORE Member Company Response: Develop a purchasing policy in 2013 that addresses organic purchasing practices 2. DISTRIBUTION & SOURCING Narrative Description We receive inbound ingredients primarily via tractor trailer, though rail and air freight is used to a limited amount. Currently we do not have the percent breakdown for different receiving methods, but are working on implementing a tracking system with our primary freight carriers that should allow us to track these in the coming year. One area we continue to pursue is using more intermodal transportation, both for incoming ingredients and in shipping finished products when logistically it makes sense. 6 Turtle Mountain owns and operates two diesel powered shuttle trucks that transport ingredients and finished products between production and storage facilities on a daily basis. These are the only two trucks owned and operated by the company. Both trucks utilize #2 diesel fuel, which contains the 5% minimum biodiesel content under Oregon State law. No additional biofuel was used during the time period covered in this report. All other transportation and distribution is performed by contracted trucking companies and to date we have no data on these outside carriers, though we are currently establishing systems to track pounds per mile and establish distribution hot spots to allow continuous improvement. DISTRIBUTION & SOURCING METRICS & INDICATORS POLICY AND GUIDELINES, PRACTICES Policy & Guidelines: Does your company have a policy or guidelines to minimize the environmental footprint of your CORE distribution and sourcing? If so, state the policy and/or provide document or URL. (GRI 4.8, EN 26, EN 29) Member Company Response: Our informal policy is to leverage our organic purchases as a proxy for an environmental management system, thus minimizing our environmental impact. Practices: Provide a narrative describing your sourcing and distribution practices, including any conservation and efficiency CORE upgrades made since your last report, if applicable, and descriptive goals (GRI EN 18, EN 29) Member Company Response: We have very strict sourcing practices as part of our Vendor Approval and Sourcing program. All our ingredients must be vegan, kosher, and non-GMO, while meeting our strict quality control standards. Our first preference is always certified organic ingredients when available and when economically viable. Distribution is a combination of truck and rail transport, depending on lead times and cost. We plan to utilize more tracking metrics in 2013 to better our distribution footprint. PRODUCT SOURCING: MODES OF TRANSPORT Product Shipped by Truck in past year - % of total purchases by weight (use dollars if weight not available throughout this section) Member Company Response: Data not available Product Shipped by Rail in past year - % of total purchases by weight. Member Company Response: Data not available Product Shipped by Boat in past year - % of total purchases by weight. 7 Member Company Response: Data not available Product Shipped by Air in past year - % of total purchases by weight. Member Company Response: Data not available PRODUCT SOURCING: LOCALITIES Regionally1 Produced Product in past year (NOTE: please state how you define 'regional') -% total purchases by weight. (GRI EC 6) Member Company Response: Data not available Domestically Produced Product in past year - % of total purchases by weight. Member Company Response: Data not available for ingredients. All finished products are manufactured in the United States. Internationally Produced Product in past year -% of total purchases by weight. Member Company Response: Data not available PRODUCT DISTRIBUTION: MODES OF TRANSPORT Product Shipped by Truck in past year - % of total product sold by weight Member Company Response: Data not available Product Shipped by Rail in past year - % of total product sold by weight Member Company Response: Data not available Product Shipped by Boat in past year - % of total product sold by weight Member Company Response: Data not available 8 Product Shipped by Air in past year - % of total product sold by weight Member Company Response: Data not available Company vehicles: If you own or lease vehicles for distribution or other company use: VEHICLES Number and Type of Vehicles Member Company Response: 2 diesel shuttle trucks for local ingredient and finished product transfer. Average Miles per Gallon for vehicles in past year Member Company Response: 3.6 mpg FUEL CORE Total Annual Fuel Consumed (Gallons) - total gallons of gasoline, diesel, biodiesel, natural gas, etc. (GRI EN 3 and/or EN 4, EN 29) Member Company Response: Gallons of diesel consumed: 6618 gallons CORE Normalized Annual Fuel Use Per Revenue (Gallons) - Total gallons per dollars of revenue (GRI EN 3 and/or EN 4, EN 29) CORE Member Company Response: 0.000125 gallons per dollar revenue. Note: this number is a not useful figure because we currently only our own vehicle miles, which are two shuttle trucks transporting ingredients and finished goods to and from longer-term storage. Thus, these two trucks transport large quantities at large dollar value, but does not capture all the other downstream/upstream transportation. Normalized Annual Fuel Use Per Square Foot (Gallons) - Total gallons per square feet of facilities or farmland (GRI EN 3 and/or EN 4, EN 29) Member Company Response: 1.96 gallons per square foot, but with same caveat as above. 9 CORE Normalized Annual Fuel Use Per Operating Unit (Gallons) - Total gallons per pounds production (farm, processor, manufacturer only). Other businesses may enter data for an additional normalization factor (besides revenue and facility square feet) here if they use one (GRI EN 3 and/or EN 4, EN 29) Member Company Response: 0.00533 gallons per unit produced, with same caveat as above. CORE Renewable Fuel % of Total in past year --biodiesel, ethanol, or other as a % of total fuel. State type and blend used (GRI EN 18) Member Company Response: All diesel consumed in last year is B5 (5% biodiesel), which Oregon mandates in all #2 diesel Provide a narrative describing fuel practices and/goals. If using biofuel describe feedstock. Member Company Response: n/a EFFICIENCY Cube Utilization of Vehicles - % cube utilization. The product volume in cubic feet divided by the vehicle transport space volume in cubic feet Member Company Response: Data currently not available GOALS CORE Please state any numeric improvement goals for Distribution and Sourcing. Member Company Response: Improvements are currently qualitative in nature, but conversations to pull more data from distribution are ongoing. 3. ENERGY USE Narrative Description Our company-owned manufacturing facilities draw 100% of their energy needs from the grid operated by the Springfield Utility Board. Power sources for this grid include 82% renewable hydropower, with the remainder coming from nuclear, wind, biomass, gas, and coal. Annual energy usage over the past 12 months through September of this year amounted to 4.23 million KWH. Energy conservation has been an ongoing focus, particularly with refrigeration systems and lighting, and in the past year the company has partnered with Cascade Energy and our local utility board to cut energy costs equal to taking 28 residential homes off the grid for a year. Examples of energy-saving measures implemented in the last year include upgrading the remaining lighting in our warehouses and outdoor locations from halogen and/or T-12 fluorescents to energy-saving T-8 fluorescents. 10 Our facilities use natural gas to heat water for production and our boiler. ENERGY USE METRICS & INDICATORS POLICY AND GUIDELINES, PRACTICES CORE CORE Policy & Guidelines: Does your company have a policy or guidelines in place regarding energy conservation, energy use or renewable energy? If so, state policy and/or provide document or URL. (GRI 4.8, EN 7) Member Company Response: Company policy is to aim for continuous improvement in normalized energy efficiency. With most (82%) of local energy production coming from renewable hydroelectric through the Springfield Utility Board, our primary focus is on energy conservation. Practices: Provide a narrative describing your energy conservation, use and purchasing practices, including any conservation and efficiency upgrades made since your last report, if applicable, and descriptive goals (EN 5, EN 7) Member Company Response: Our company-owned manufacturing facilities draw 100% of their energy needs from the grid operated by the Springfield Utility Board. Power sources for this grid include 82% renewable hydropower, with the remainder coming from nuclear, wind, biomass, gas, and coal. Since our last report, we have taken further steps to conserve energy usage. Examples include purchasing a much more energy efficient air compressor and upgrading our remaining warehouse and outdoor lighting to CFLs. We have also partnered with Bonneville Power Administration and our local utility and have been approved to participate in the Track & Tune energy conservation program. Participation in this program includes regular energy audits, consultations with electrical engineering staff in order to promote further energy conservation. ENERGY USE CORE Total Annual Energy Use (BTUs) Sum of energy types below, converted to BTUs (see Tracking Template for BTU conversions, auto-calculated when you enter data) (GRI EN 3, EN 4) Member Company Response: total energy consumed for our two production facilities in Springfield: 20,142,688,189 Btu Annual Electric Purchased (kWh) – kWh purchased; if possible specify utility mix: % coal, nuclear, geothermal, wind, hydro, solar, etc. (GRI EN 4) Member Company Response: total for our two production facilities: 4228883 kWh; energy mix through our local electrical utility is 82% renewable hydropower, 10% nuclear, 6% coal, and the remainder is a mixture of wind, biomass, and natural gas. Annual Natural Gas Purchased (Therms) - therms purchased (GRI EN3) Member Company Response: total natural gas consumed for our two production facilities: 55467 Therms 11 Annual Propane Purchased –Gallons purchased (GRI EN 3) Member Company Response: n/a Annual Other Facility Power Purchased, BTUs (e.g., steam, wood) in BTUs (GRI EN 3/4) Member Company Response: n/a Annual Renewable Electrical Power Produced Onsite (kWh) – renewable electricity (solar, wind) in kWh and as a percentage of total electrical power (GRI EN 3, GRI EN 18) Member Company Response: none Annual Renewable Gas Power Produced Onsite (Therms) – renewable gas (e.g., methane digester) in therms and as a percentage of total gas power (GRI EN 3, GRI EN 18) Member Company Response: n/a NORMALIZED ENERGY CORE Normalized Annual Facility Energy per Annual Revenue (BTUs) -total facility energy converted to BTU's per annual revenue (GRI EN 3, EN 4) Core Member Company Response: 355.98 btu’s per U.S. dollar CORE Normalized Annual Facility Energy per Square Foot (BTUs) -total facility energy converted to BTU's per total square feet of facilities or farmland (GRI EN 3, EN 4) Member Company Response: 1,438,763 btu/sq.ft. CORE Normalized Annual Facility Energy per Operating Unit (BTUs) -total facility energy converted to BTU's per pounds of production (farms, processors, manufacturers only). Other businesses may enter data for an additional normalization factor (besides revenue and facility square feet) here if they use one. (GRI EN 3, EN 4) Member Company Response: 8079 btu/unit production RENEWABLE GRID ENERGY CORE Total Annual Renewable Electricity (wind, solar, small-scale low-impact hydro) purchased directly from utility (kWh) (GRI EN 18) CORE Member Company Response: none Total Annual Renewable Energy, Purchased and Generated (BTUs) (GRI EN 18) 12 Member Company Response: the only form of renewable energy purchased directly is B5 biofuel, equivalent to 356 gallons of B100. Electricity from SUB is approximately 82% renewable hydropower. Proportional Annual Renewable Electricity Purchases –% of total facility electricity purchases comprised of green energy purchased from utility providers as a (GRI EN 18) Member Company Response: 82% hydropower, 2% biomass, 1% wind energy Proportional Renewable Energy Purchased and Generated –% of total energy use comprised of green energy purchased and generated (GRI EN 18) Member Company Response: same as above. EFFICIENCY Energy Saved Due to Conservation and Efficiency Upgrades in Facilities in past year –units by energy type and total % energy reduction in past year. (GRI EN 5, EN 7) Member Company Response: 75,460 kWh (savings calculated from warehouse lighting retrofit and new air compressor) GREEN BUILDING Green Building Standards related to Energy Conservation & Renewables - for remodels, new construction and facility management/operations, list certifications and/or provide a narrative describing practices. (GRI 4.12, EN 7) Member Company Response: Facilities including manufacturing and offices have been RE:Think certified through Bring Recycling. GOALS CORE Please state any numeric improvement goals for Energy Use (GRI EN 7) Member Company Response: our current goal is continuous improvement in the area of energy efficiency – no target achievement levels have been set. 4. CLIMATE CHANGE AND AIR EMISSIONS Narrative Description All calculations in this section were generated using the EPA’s Small Business GHG Calculator. Scope 1 emissions from the previous 12 months of natural gas combustion resulted in 376 metric tons CO2 equivalent. To help make a difference in indirect emissions, the Company has implemented a Alternative Transportation Program that encourages employees to commute using alternative transportation such as biking, walking, taking the bus, or carpooling. So far, 26 employees 13 have signed up to participate in the program, representing 17% of the total work force – a two point increase over 2011. We anticipate that this program will continue to grow in popularity and effectiveness during the coming months. CLIMATE CHANGE AND AIR EMISSIONS METRICS & INDICATORS POLICY AND GUIDELINES, PRACTICES CORE Policy & Guidelines: Does your company have a policy or guidelines in place regarding climate change, greenhouse gas emissions and/or air pollution? If so, state the policy and/or provide document or URL. (GRI 4.8, EN 18) Member Company Response: No formal written policy to date. CORE Practices: Provide a narrative describing your greenhouse gas measurement and reduction, and air pollution prevention practices, including any improvements made since your last report, if applicable, and descriptive goals (GRI EN 18) Member Company Response: We annually measure the carbon footprint of our frozen dessert operations, and recently completed a Life Cycle Analysis that measured the carbon footprint and air emissions of our entire coconut and almond supply chain. Our employee alternative commuting program encourages employees to leave their cars at home and ride, bike, carpool, or take the bus, further reducing emissions associated with our business. GHG EMISSIONS CORE Total Annual Direct/Scope 1 GHG Emissions (metric tons CO2) – Total CO2 equivalents from fuels burned on-site and in company-owned vehicles (GRI EN 16) Member Company Response: 376 metric tons CO2 CORE Total Annual Indirect/Scope 2 GHG Emissions (metric tons CO2e) –from electricity purchased though a utility for all facilities owned or leased Do not include RECs or offsets here. (GRI EN 16) Member Company Response: 1656 metric tons CO2 Total Annual Indirect/Scope 3 GHG Emissions (metric tons of CO2e) - total metric annual tons of CO2e from emissions related to activities not controlled by the company, but that are necessary for operation (e.g., ingredient production, packaging, contract manufacturing, shipping, distribution, commuting, business travel, product use, disposal. Include data on any product/service lifecycle emissions you've calculated or estimated. (GRI EN 17) 14 Member Company Response: 392 metric tons CO2 from employee commuting CORE Total Annual Gross GHG Emissions (metric tons CO2e): Sum of Scope 1, 2 and 3 emissions, metric tons CO2e (GRI En 16, EN 17) Member Company Response: 2,423 metric tons CO2 CORE Total Annual Renewable Energy Credits (RECs) and offsets purchased (metric tons CO2e) Member Company Response: none CORE (if applicable) Provide a narrative of REC provider and program. (GRI EN 18). At minimum, state type, provider and verification/certification for offsets. Member Company Response: n/a CORE Total Annual Net GHG Emissions (metric tons CO2e): Sum of Scope 1, 2 and 3 emissions minus RECs and offsets, metric tons CO2e (GRI En 16, EN 17) Member Company Response: 2,423 metric tons CO2 CORE State method used to measure and calculate GHG emissions, and source of any emissions factors) and other conversions Member Company Response: EPA Simplified GHG Emissions Calculator (version 3.1) Normalized Annual Gross GHG Emissions per Revenue (metric tons CO2e) -total direct, indirect and other GHG emissions in metric tons of CO2 equivalent per annual revenue (GRI EN 16, EN 17) Member Company Response: 4.28 x10-5 metric tons CO2 per dollar revenue 15 CORE Normalized Annual Gross GHG Emissions per Square Foot (metric tons CO2e) -total direct, indirect and other GHG emissions in metric tons of CO2 equivalent per square feet of facilities or farmland (GRI EN 16, EN 17) Member Company Response: 0.173 metric tons CO2 per square foot CORE Normalized Annual Gross GHG Emissions per Operating Unit (metric tons of CO2e) -total direct, indirect and other GHG emissions in metric tons of CO2 equivalent per pounds of production (farms, processors, manufacturers only). Other businesses may enter data for an additional normalization factor (besides revenue and facility square feet) here if they use one. (GRI EN 16, EN 17) Member Company Response: 1.4 x 10-3 metric tons CO2 per unit produced OTHER GHG EMISSIONS GHG Emissions not covered by the Kyoto Protocol (metric tons of CO2e) – total annual metric tons CO2e of CFCs, NOx, SOx, Black Carbon, etc. (GRI EN 20) Member Company Response: no data currently available OZONE DEPLETING SUBSTANCES Substances in Montreal Protocol - Total annual ozone depleting substances such as Halogenated hydrocarbons that have shown to play a role in ozone depletion, in appropriate units. (GRI EN 19) Member Company Response: no data currently available EFFICIENCY Annual Emissions Reduced by Efficiency Upgrades, metric tons of CO2e - Specify total and list the upgrades in facilities and/or vehicles (i.e. new hybrid electric vehicle) (GRI EN 18) Member Company Response: none PARTICULATE EMISSIONS Particulate emissions, if required to measure & report (in appropriate unit/s) (GRI EN 20) Member Company Response: no data currently available EMPLOYEE COMMUTING AND BUSINESS TRAVEL Provide a narrative describing employee commuting programs including rideshare, bicycle commuting, use of public transportation. (GRI EN 18, 29) 16 Member Company Response: Turtle Mountain offers alternative commuting options for all employees, where biking and carpooling to work earns points toward gift certificates. The Geared for Success Grant program provides up to $500 for employees to purchase a bike and/or related gear for commuting. The Company also provides free monthly bus passes for interested employees. Total Annual Emissions from Workforce Commuting (metric tons of CO2e) – metric tons of CO2e. (GRI EN 17, EN 29) Member Company Response: 392 metric tons CO2 Average Annual Emissions per Worker, metric tons of CO2e –metric tons of CO2e. (GRI EN 17, EN 29) Member Company Response: 2.62 metric tons CO2 Total Annual Emissions from Corporate Air travel (metric tons of CO2e) –metric tons of CO2e. (GRI EN 17, EN 29) Member Company Response: no data currently available Annual Emissions Offset from Employee Commuting and business travel (metric tons of CO2e) –Also specify emissions offset provider, and their verification and certification processes (GRI EN 18) Member Company Response: none GOALS CORE Please state any numeric improvement goals for Climate Change and Air Emissions (GRI EN 18) Member Company Response: currently working on quantifying goals 5. WATER USE AND QUALITY Narrative Description Water is a critical part of our production process, from use as an ingredient to washing and cleaning the production facility to ensure the strictest food safety standards. Production facilities used roughly 10 million gallons of water in the previous 12 months. We are actively looking at ways of decreasing this water footprint through conservation efforts, and some projects are already in the works, such as our recent purchase of a new cooling tower technology that is projected to save ~1.5 million gallons of water per year beginning in 2013. In the meantime, Turtle Mountain has made the decision to offset our production facility’s water footprint by partnering with the nonprofit Bonneville Environmental Foundation and their Water Restoration Certificates™ program. We’re also a proud donor to the McKenzie River Trust – a Eugene-based conservancy whose work protects water quality and fish habitat in the same watershed we draw our water from for our manufacturing. 17 WATER USE AND QUALITY METRICS & INDICATORS POLICY AND GUIDELINES, PRACTICES CORE CORE Policy & Guidelines: Does your company have a policy or guidelines in place regarding water usage and pollution prevention, including the handling of wastewater discharges? If so, state the policy and/or provide document or URL. (GRI 4.8) Member Company Response: Our company meets local and Federal laws concerning wastewater discharge and strives for continuous improvement in this area. Our policy states specifically that no wastes are allowed to be dumped into storm drains and that the pH of wastewater must comply with local regulations prior to dumping. Practices: Provide a narrative describing water use and pollution prevention practices, including any improvements made since your last report, if applicable, and descriptive goals. Also state water sources. (GRI EN 9) Member Company Response: We track both our potable and waste water usage with the goal of minimizing consumption per unit of volume produced. We recently approved a new cooling tower system for installation that we estimate will save over 1.5 million gallons of water per annum, and this is scheduled to be installed by January 2013. We are strong supporters of water conservation in Oregon through our involvement with the Bonneville Environmental Foundation and the McKenzie River Trust. All water for our Springfield Oregon manufacturing is sourced through Springfield Utility Board, which pulls the majority of water from well fields tapped into an underground aquifer and supplements this with water drawn from the Middle Fork of the Willamette River. We actively support the conservation work of the McKenzie River Trust, a great organization that works to preserve water quality and wildlife habitat in our watershed. WATER USAGE Annual Potable Water Consumed (Gallons) - Total water in gallons (GRI EN 8) Member Company Response: 11,086,108 gallons CORE Annual Non-potable Water Consumed (Rainwater, etc) (Gallons) - gallons and percentage of total water used) (GRI EN 8) Member Company Response: none Total Annual Water Consumed (Gallons) - Total potable and non-potable water in gallons (GRI EN 8) Member Company Response: 11,086,108 gallons Normalized Annual Water Use, per Revenue (Gallons) -total annual water use in gallons per annual revenue (GRI EN 8) 18 Member Company Response: 0.20 gallons per dollar revenue CORE Normalized Annual Water Use, per Square Foot (Gallons) -total annual water use in gallons per total square feet of facilities or farmland (GRI EN 8) Member Company Response: 792 gallons per square foot CORE Normalized Annual Water Use, per Operating Unit (Gallons) -total annual water use in gallons per pounds of production (farms, processors, manufacturers only). Other businesses may enter data for an additional normalization factor (besides revenue and facility square feet) here if they use one. (GRI EN 8) Member Company Response: 6.35 gallons per unit production WASTE WATER Annual Waste Water Discharge (Gallons) - gallons purchased (GRI EN 21) Member Company Response: 8,076,858 gallons Annual Waste Water Recovered (Gallons) - gallons recovered and reused (GRI EN 10) Member Company Response: None. Interestingly, we were seriously considering installing a water reclamation system so we could reuse our post-wash rinse water as a pre-rinse for the next wash but with our strong focus on allergen control this idea proved to be untenable due to the slight possibility of allergen cross-contamination. The risk proved to be too high, so we are now turning our attention to other ways of conserving water at our manufacturing facilities. WATER-EFFICIENCY Annual Water Saved Due in Past Year to Conservation and Efficiency Upgrades (Gallons) –gallons Member Company Response: none WATER QUALITY Annual Waste Water Particulate Load (ppm) - in parts per million (ppm) (GRI EN 21) 19 Member Company Response: 7800 ppm (BOD); 2600 ppm (TSS) List any toxic, non-biodegradable, persistent substances used and efforts to replace these Member Company Response: no known persistent toxics in wastewater stream. We have switched out our floor cleaner, hand wash soap, and window cleaner to biodegradable non-toxic versions in our continuing effort to minimize environmental impact. GREEN BUILDING Green Building Standards related to Water Use and Pollution Prevention – for remodels, new construction and facility management/operations, list certifications and/or provide a narrative describing practices. (GRI 4.12) Member Company Response: we utilize water weenies for all spray hoses and all water faucets have low flow fixtures. GOALS CORE Please state any numeric improvement goals for Water Use and Quality Member Company Response: decrease water usage 5% per unit production for 2013 6. SOLID WASTE REDUCTION Narrative Description Turtle Mountain has adopted a Zero Waste goal for our production facilities. While we have a long way to go towards reaching this goal, we have been making steady progress. We already have systems in place to recycle all cardboard, plastic bottles, stretch wrap, and mixed plastics through our hauler. We also recycle all our cardboard-reinforced totes, and have found creative ways of keeping our large plastic drums out of the waste stream by selling them to a local businessman who makes rain catchers out of them. Since all the “low hanging fruit” is now mostly gone, we are setting our sights on more creative ways of diverting waste from the landfill. Total diverted recycling stream in the previous 12 months equaled 143 tons. Our offices have also been an area where we look to reduce waste and encourage resource conservation through our internally developed Green Office Program (GOP). This program, launched in July of last year, is designed to incentivize participation through fun giveaways and recognition in our employee newsletter. Since implementing this program, all our offices have switched over to a 100% recycled paper products (bathroom tissue, paper towels, napkins, copy paper), set up mixed recycling stations as well as for hard to recycle items like rechargeable batteries, old CFL light bulbs, and Styrofoam. We have also partnered with a hauler who will take any coated paper items like outdated sales sheets, milk and juice cartons, and ice cream cartons. Currently, we are looking into a way to compost organic wastes to divert these from the landfill. 20 SOLID WASTE REDUCTION METRICS & INDICATORS POLICY AND GUIDELINES, PRACTICES Policy & Guidelines: Does your company have a policy or guidelines in place regarding waste reduction or treatment, including animal wastes? If so, state the policy and/or provide document or URL. (GRI 4.8) Member Company Response: Company policy is to minimize waste continuously striving to eliminate waste and by recovering as much material from the waste stream as possible through recycling. Practices: Provide narrative describing waste sources and waste reduction and management practices, including any CORE improvements made since your last report, if applicable, and descriptive goals Member Company Response: The Company has a comprehensive recycling program, and in the last year has further increased recycling by working with our recycling partner to take additional single-sorted material including white sandwich box liners. ANNUAL WASTE AND BYPRODUCTS CORE CORE Total Annual Waste and byproducts (Tons) Specify breakdown by types below: Member Company Response: 320 tons total waste generated Annual Landfill and Incinerator Output (Tons) -tons of solid waste set to landfill and incinerator (GRI EN 22) Member Company Response: 177 tons Total Annual Hazardous Waste (Tons) (GRI EN 22) Member Company Response: none Total Annual Recycling Output (Tons) - tons recycled (GRI EN 22) Member Company Response: 143 tons Total Annual Compost Output (Tons) - tons composted, through 3rd party or onsite (GRI EN 22) Member Company Response: none Total Annual Reuse (Tons) - tons diverted from landfill through reuse (internally or externally) (GRI EN 22) 21 CORE Member Company Response: none (reuse of pallets, totes, HDPE pails, and cloth towels not tracked) Total Annual Biomass (Tons) - tons diverted from landfill through biomass (does not include waste to energy/incineration) (GRI EN 22) Member Company Response: none Total Annual Other Materials Diverted from Landfill (Tons) – tons of other materials, specify type/s and method of diversion (e.g., animal feed) (GRI EN 22) Member Company Response: 0 (we recycle grease trap waste via Encore Oils, but the amount of grease is only a few hundred pounds annually) Total Annual Waste Diverted From Landfill (Tons) – tons and % of total waste/byproducts – (GRI EN 22) Member Company Response: 143 tons Proportional breakdown of byproducts stream (% landfill, compost, recycling, reuse etc.) by weight in pounds (not volume) (GRI EN22) Member Company Response: 55% landfill, 45% recycling, 0% compost or reuse Normalized Annual Waste/Byproducts per Revenue (Tons) total annual waste and byproducts in tons per annual revenue (GRI EN 22) Member Company Response: 0.005 tons waste per $1000 revenue CORE Normalized Annual Waste/Byproducts in per Square Foot (Tons) total annual waste and byproducts in tons per square feet of facilities or farmland (GRI EN 22) Member Company Response: .022 tons per sq.ft. CORE Normalized Annual Waste per Operating Unit (Tons) - total annual waste and byproducts in tons per pounds of production (farms, processors, manufacturers only). Other businesses may enter data for an additional normalization factor (besides revenue and facility square feet) here if they use one (GRI EN 22) Member Company Response: 0.0002 tons waste per unit finished product Animal Wastes – Please describe how animal wastes are handled and efforts to divert from landfills and prevent air, water and soil pollution Member Company Response: n/a (we are a vegan food company, and therefore do not process or handle any animal wastes) GREEN BUILDING 22 Green Building Standards related to Source Reduction & Landfill Diversion - for remodels, new construction and facility management/operations, list certifications and/or provide a narrative describing practices. (GRI 4.12) Member Company Response: n/a GOALS CORE Please state any numeric improvement goals for Solid Waste Reduction Member Company Response: our long-term goal is to be a zero-waste production facility, though no immediate time frame has been identified 7. PACKAGING AND MARKETING MATERIALS Narrative Description Turtle Mountain uses a variety of packaging materials for our product lines. The number one through number five plastics used on our yogurts and cultured products are accepted for recycling by most municipalities. The beverage and creamer cartons are accepted for recycling where facilities exist, which according to the Carton Council is currently about 30% of U.S. households. The ice cream cups are not considered recyclable by Material Recycling Facilities (MRFs) because of the tandem poly coating, which does not allow the material to be easily re-pulped. We are actively examining ways of increasing the recyclability of our beverage and ice cream product lines in the future. Our metrics are not currently tracking the percent renewable material in our packaging but we will be tracking those numbers in the coming year. We strive to have our marketing materials printed on either Sustainable Forestry Initiative or Forestry Stewardship Council, but we’re still working on standardizing this practice across our printing contractors. We also are pushing to use at least 30% recycled paper for all promotional and marketing materials and will be tracking our progress for this metric going forward. Our business cards are printed on 80% recycled paper, 60% post-consumer. All inks used are soy-based and low in VOCs. PACKAGING AND MARKETING MATERIALS METRICS AND INDICATORS POLICY AND GUIDELINES, PRACTICES CORE Policy & Guidelines: Does your company have a policy or guidelines in place regarding packaging materials and marketing materials? If so, state the policy and/or provide document or URL (GRI 4.8, EN 26) Member Company Response: Our policy is to incorporate recycled and/or certified paper (ex: FSC, SFI) into our purchasing whenever possible, and to use packaging that first of all protects to product while also striving to minimize end-of-life recovery issues. 23 Practices: Provide narrative describing packaging and marketing materials practices, including any improvements made since your last report, if applicable, and descriptive goals Member Company Response: Plastics: all plastics used in packaging are recyclable (either #5 PP or #2 HDPE); paperboard: all paperboard packaging is either cardboard (made of 30% recycled pulp) or in the case of our frozen novelty cartons is 100% recycled paperboard. Ice cream pints/quarts are not currently recyclable. Paper for office printing is made from 100% post-consumer recycled material, while we strive to use either certified (SFI or FSC) or paper with at least 30% recycled content. PACKAGING AND MARKETING MATERIALS USE Total Annual Packaging and marketing materials (pounds) – pounds by material type (GRI EN 1, EN 21) Member Company Response: no data currently available CORE Total Annual Packaging and Marketing Materials Eliminated Due to Reduction Measures (pounds) –pounds eliminated in past year (GRI EN 1, EN 26) Member Company Response: no reductions were achieved this year, but for 2013 we have several projects in the works. PACKAGING DESIGN EFFICIENCY Cube Utilization - Mean, median and range % cube utilization across product line. Volume of full pallet of product in cubic inches divided by total pallet volume available (length X width X height cubic inches). (GRI EN 26) Member Company Response: no data currently available Packaging to Product Ratio (% by Weight) - as a % of total product weight. Mean, median and range across product line. Divide total packaging only weight (primary through tertiary packaging and pallet) by total net product weight Member Company Response: no data currently available PACKAGING AND MARKETING MATERIALS INPUTS Amount of Renewable Content of Packaging Materials and Marketing Materials (% by weight) CORE - % of total packaging and marketing materials by weight - specify any % of GMO-based materials, if used and note steps to eliminate Member Company Response: beverage packaging (gabletops and aspeptic Tetrabriks): 85% renewable content novelty frozen desserts: 100% renewable packaging (minus the poly sleeve for food contact surface) Pint/quart cups: 90% renewable content Yogurt cups: 0% renewable content. We are always looking for feasible replacements for CORE 24 CORE plastic yogurt cups but options are currently very limited. Marketing materials: 95% renewable content Amount of Recycled Content of Packaging Materials and Marketing Materials (% by Weight) -% of packaging and marketing materials by weight that are made from recycled material (GRI EN EN 2, 26) Member Company Response: no data currently available 3rd Party Certified Virgin Packaging Materials and Marketing Materials (% by Weight) -% of virgin packaging and marketing materials by type and weight that are certified for responsible sourcing such as Forest Stewardship Council Member Company Response: We try to purchase SFI or FSC certified marketing materials when possible, but do not currently track these purchases. Environmentally Responsible Inks -% of packaging and marketing materials that are printed with vegetable-based inks or other environmentally-preferable inks (GRI EN 26) Member Company Response: 100% of our printers use vegetable based inks PACKAGING WASTE CORE CORE CORE Provide a narrative describing what your company does to encourage end user (business customer, consumer), reuse, recycling, or composting. (GRI EN 26) Member Company Response: Amount of Packaging that Can be Recycled by End User (customer, consumer), in their locality (% by Weight) - % of total packaging by weight (GRI EN 26) Member Company Response: no data currently available Amount of Packaging that Can be Composted by End User (customer, consumer), separating home composting and industrial scale (% by Weight) - % of total packaging by weight (GRI EN 26) - specify any % of GMO-based materials, if used and note steps to eliminate Member Company Response: no packaging is currently compostable Amount of Reusable Packaging (% by Weight) - % of total packaging by weight (GRI EN 26) Member Company Response: no data currently available for packaging by weight Ed-user Reclamation Infrastructure: Describe steps taken to evaluate capacities for end-user recycling, composting, etc in their localities and efforts to help improve this (e.g., advocacy for recycling and composting expansion, funding collection programs) (GRI EN 26) 25 Member Company Response: The company has evaluated data from the Carton Council on recycling infrastructure for gabletop cartons and tetrabriks, and found that about 35% of consumers have access to facilities in their local areas. Frozen novelty cartons are readily recyclable in most municipalities, whereas ice cream cups are no recyclable due to lack of infrastructure. The Company frequently consults with Earth 911 for the most up to date recycling infrastructure data. Take Back Policies and Programs – Do you provide services to take back product packaging from business customers or consumers? Note volume in pounds collected (GRI EN 26, EN 27) Member Company Response: The Company does take back metal drums and cardboard totes from certain customers where we have our own trucks deliver. PACKAGING & MARKETING MATERIALS MANUFACTURE IMPACTS Describe and/or quantify any lifecycle environmental impacts you've assessed for packaging and/or marketing materials Member Company Response: The company has completed a full Life Cycle Assessment of our beverage packaging (gabletop and Tetrabrik containers). The baseline impacts are as follows: GABLETOP Energy demand: 6.08 MJ eq. Global Warming: 0.54 kg CO2 eq. Ozone Depletion: 2.8 E-08 kg CFC-11 eq. Water Consumption: 11.0 liter H2O eq. Acidification: 0.19 H+ moles eq. Eutrophication: 3.0 E-04kg N eq. Smog: 0.0022 kg NOx eq. Solid Waste: 0.12 kg SW eq. TETRABRIK Energy demand: 5.8 MJ eq. Global Warming: 0.36 kg CO2 eq. Ozone Depletion: 2.2 E-08 kg CFC-11 eq. Water Consumption: 8.04 liter H2O eq. Acidification: 0.17 H+ moles eq. Eutrophication: 3.0 E-04 kg N eq. Smog: 0.0022 kg NOx eq. Solid Waste: 0.074 kg SW eq. Labor Practices: Explain how you evaluate labor practices associated with packaging manufacture 26 and raw materials sourcing, and how you ensure good practices are used Member Company Response: no data currently available GOALS CORE Please state any numeric improvement goals for Packaging and Marketing Materials (GRI EN 26) Member Company Response: The Company’s stated goal is to continually strive to reduce nonrenewable materials from our packaging supply chain. 8. LABOR Narrative Description Turtle Mountain is an equal opportunity employer and has a full-time staff of approximately 150 between our production facilities, sales force, and office personnel. In addition, we contract with a local employment agency to source temporary help to support our operations on an as-needed basis. We currently do not track our employee composition by gender or ethnicity. Employee benefits include health insurance, life insurance, 401K, dental insurance, accrued vacation time, sick leave, and nine paid holidays, and a personal volunteer day off, where all full time employees are eligible to take one work day per annum and volunteer that time to a non-profit or charity of their choice. Our Safety and Training coordinator ensures that all production employees receive initial safety training and annual refresher training specific to their job. Some jobs such as forklift operator or maintenance engineer require special training or certificates to perform their jobs safely and to comply with regulations. Limited fair trade ingredients are purchased currently. Specifically, our organic dehydrated cane juice and organic cocoa are fair trade certified. At the moment however we are making no claims as to the fair trade content of our finished products. LABOR METRICS AND INDICATORS POLICY AND GUIDELINES, PRACTICES CORE CORE Policy & Guidelines: Does your company have policies in place to ensure fair working conditions in your workplace? If so, state the relevant policies. (GRI 4.8) Member Company Response: Our Employee Manual contains sections dedicated to fair working conditions and fairness in the workplace such as under Working Guidelines – General Conduct “It is expected that all employees conduct themselves in a manner consistent with common sense rules of behavior. The Company rules and standards of conduct are intended not only to promote a safe working environment, but also to protect individual rights” Practices: Provide narrative describing working conditions, benefits, feedback programs and training and educational assistance programs, including any improvements made since your last report, if applicable, and descriptive goals 27 Member Company Response: Employee benefits include health insurance, life insurance, 401K, dental insurance, accrued vacation time, sick leave, and nine paid holidays. A recent addition to our benefits which was suggested by our Sustainability Task Force includes a personal volunteer day off, where all full time employees are eligible to take one work day per annum and volunteer that time to a non-profit or charity of their choice. Our Safety and Training coordinator ensures that all production employees receive initial safety training and annual refresher training specific to their job. Some jobs such as forklift operator or maintenance engineer require special training or certificates to perform their jobs safely and to comply with regulations. WORKFORCE COMPOSITION & DIVERSITY CORE CORE Total Workplace Employment – by type, employment contract, and region. (GRI 2.8) Member Company Response: total full-time employees: 152. Greater than 90% are located at our facilities in Springfield, while the remainder are in sales or design positions across the nation. The remainder of workforce needs for production are provided through a local temp agency. Workforce Diversity -employees per category according to gender, age, ethnic/racial, and other indicators of diversity. (GRI LA 13) Member Company Response: no data currently available Equal Opportunity Employer – state policy and/or provide document or URL Member Company Response: It is the Company’s policy to provide equal employment opportunities for all applicants and employees. The Company employs, retains, promotes, terminates and otherwise treats any and all applicants and employees on the basis of merit, qualifications, and competence. The Company does not unlawfully discriminate on the basis of race, color, religion, sex, sexual orientation, national origin, age, medical condition, disability, marital status, veteran status or any other category protected by state or federal laws. The Company also makes reasonable accommodations for disabled employees. COMPENSATION Employee Health Care Benefits - % of health care costs (health, vision, and dental) covered for employees. Note if this is specific to full-time, etc. (GRI EC 1) Member Company Response: Full-time employees are available Employee Health Care Benefits - % of total, full-time and part-time employees eligible for employer health care benefits (GRI EC 1) Member Company Response: 100% of full-time employees are eligible for benefits. Part time employees are not eligible for benefits. Employee 401(k) Plan or Other Retirement Plan Contribution - % of total, full-time and part-time employees eligible for employer 401K plans (GRI EC 3) 28 Member Company Response: 100% of full-time employees are eligible for benefits. Part time employees are not eligible for benefits. Employer 401(k) Matching Contribution or Other Retirement Plan - total % of employer matching of employee contribution to 401K plans (GRI EC 3) Member Company Response: Company will fund 100% of 401k salary deferral contributions up to 3% of compensation plus 50% of 401k salary deferral contributions between 3% and 5% of compensation. Profit Sharing – % of annual profit sharing and distribution policy (GRI EC 1) Member Company Response: n/a Ratio between lowest and highest paid employee. Member Company Response: no data currently available % of employees receiving living wage for local economy (GRI EC 5) Member Company Response: no data currently available EMPLOYEE ENGAGEMENT & RETENTION Annual Total and Rate of Employee Turnover - by age group, gender, and region. Member Company Response: no data currently available Employee Satisfaction - % of total employees surveyed and % satisfaction for most recent survey. State year of last survey and frequency of surveys. (GRI 4.16) Member Company Response: satisfaction surveys are annual, and the last satisfaction survey was in November 2011. Employee Representation - Narrative stating how employee concerns are represented in operating decisions, such as employee board position, % unionized, etc. (GRI 4.16, LA policy, LA 6) 29 Member Company Response: Employee concerns are addressed through the Company’s Open Door Policy, which states in part that “our “open door policy” permits employees to discuss any complaints or problems with members of management at any level, up to and including the President and Vice Presidents. This is normally done by making an appointment away from the immediate work area. We believe that problems connected with your employment at the Company can and should be settled as soon as they arise through an informal discussion with your supervisor or manager. HEALTH AND SAFETY CORE Number of Recordable Injuries and Illnesses Under OSHA - total number of recorded incidents (GRI LA 7) Member Company Response: 0 incidents CORE Accident Frequency Ratio for Company Vehicles [AFR] -accidents per 1 million miles of vehicle operation (GRI LA 7) Member Company Response: none CORE Injury Frequency Ratio [IFR] -injuries per 100,000 hours worked (GRI LA 7) Member Company Response: none Office ergonomics: Does the employer offer ergonomic training, equipment and/or assessments? Member Company Response: Wellness programs: Provide narrative and participation data for any unique wellness programs offered such as on-site gym, fitness classes and activities, incentives for healthy choices (weight loss, smoking cessation), gym membership reimbursement, education, voluntary screenings, etc. Member Company Response: Production employees assessed for ergonomics, but not office personnel currently TRAINING PROGRAMS CORE Average Annual Employee Training (Hours) –average hour per employee (GRI LA 10, Safety GRI LA 8) Member Company Response: 57 hours average per year 30 Annual Expenditure, Employee Training and Education - total expenditures for employee training and education. (GRI LA 11) Member Company Response: $200 for HazWoper training; all other training performed in-house. ETHICAL SOURCING CORE CORE CORE Policy: Does your company have a policy or standards in place regarding ethical sourcing and supplier practices to evaluate and improve key areas such as child and forced labor, discrimination, harassment, freedom of association, health & safety, wages & benefits, working hours, diversity, etc. This may include a supplier code of conduct; requiring adherence to specific ILO or other international labor and human rights standards, transparency for labor and wage practices, and verification of adherence to applicable laws; and direct programs with suppliers? If so, state the policy or standards and/or provide document or URL, and note how these are implemented and verified. (GRI 4.8) Member Company Response: The Company is currently working with the SFTA supplier task force to formulate a supplier code of conduct. Practices: Provide a narrative describing your ethical sourcing practices, and how you ensure good practices related to child and forced labor, discrimination, harassment, freedom of association, health & safety, wages & benefits, working hours, diversity, etc. You may find it appropriate to combine with the below question. (GRI HR 2) Member Company Response: Our current approach relies on third-party certifications such as Rain Forest Alliance (organic sugar) and EcoCert (select organic coconut) but is not comprehensive throughout the supply chain. This approach will be replaced with a comprehensive supplier code of conduct once completed by the SFTA task force. Verification: Provide vendor statements on their labor practices and relevant 3rd Party Certifications. (GRI HR 2) Member Company Response: no data currently available Applicable Certifications: List 3rd Party ethical sourcing Certifications and audited company-managed ethical sourcing programs (GRI 4.12) Member Company Response: n/a Sales or Purchasing: Sales or purchasing of products and/or ingredients sourced under 3rd party trade/labor certifications and company ethical sourcing programs, reporting 3rd party and company programs separately -% of sales (farms) or purchases (all others) by weight (GRI HR 2) Member Company Response: no data currently available GOALS CORE Please state any numeric improvement goals for Labor Member Company Response: Our goal in 2013 is to have at least 90% of all suppliers fill out and return a supplier 31 code of conduct and begin tracking 3rd party certified ingredients. 9. ANIMAL CARE Narrative Description As a non-dairy and vegan food company, Turtle Mountain leaves no impact regarding the use of animal ingredients in any of our products. We are on the other hand active participants in giving to non-profit organizations such as the Sea Turtle Restoration Project (www.seaturtles.com) and Farm Sanctuary (www.farmsanctuary.org). Please visit their websites for more information on these important efforts. ANIMAL CARE METRICS & INDICATORS POLICY AND GUIDELINES, PRACTICES CORE CORE Policy and Guidelines: Does your company have a policy or guidelines in place regarding humane animal care and management? If so, state the policy and/or provide document or URL. Please reference areas listed below in considering your response. (GRI 4.8) Member Company Response: As a vegan-only food company, Turtle Mountain purchases no ingredients of animal origin nor tests on any animals Practices: Provide a narrative describing animal care practices in your operations and supply chain, including any improvements made since your last report, if applicable, and descriptive goals. Member Company Response: n/a HEALTH AND WELL BEING Production Enhancement - % milk purchased/produced from cows confirmed to be free of rBST/BGH and other growth promoters, antibiotics and hormones; -% of livestock/poultry confirmed to be free of synthetic growth promoters, antibiotics and hormones of any kind. Member Company Response: n/a Breeding: Describe practices related to genetic selection, diversity, etc. Member Company Response: n/a 32 Physical Modifications - % of animals that undergo physical modifications, separated by animal type (e.g., de-beaking, tail docking, de-horning, removal of digits). If done, please explain why and how you ensure properly trained workers and humane practices are used. Member Company Response: n/a Loss & Longevity: State separately by type - % of livestock/poultry prematurely culled due to injury or illness - average age of animal at end of production. - Lameness: % lameness permitted and occurring, by animal type Member Company Response: n/a Feed - % of eggs purchased/produced from hens prohibited from feed to force molting - is force-feeding of ducks & geese to produce foie gras prohibited? - % of animals fed GMO-free diet - % of animals fed vegetarian diet with no animal byproducts or animal proteins, by type. Where animal proteins are used in feed, state reason if not an accepted best/standard practice - % cattle, bison, etc on grass-fed diet - Do all animals have adequate access to food and water at all times? - What steps are taken to ensure proper nutrition? Member Company Response: n/a LIVING CONDITIONS Eggs - % purchased/produced from cage-free hens - % purchased/produced from free-range hens. * Note how cage-free and free-range are defined and verified Member Company Response: n/a Pork - % purchased/produced from pigs not confined to crates or spaces smaller than X, including gestation crates. - % purchased from animals not confined indoors Member Company Response: n/a Veal - % purchased/produced from calves not confined to veal crates, 33 Member Company Response: n/a Milk - % purchased/produced from animals that are given access to pasture and actively graze; specify how many months/year and how many hours/day. Member Company Response: n/a Beef – average number of animals per acre, specify months/year, and hours/day on pasture, with locations of farms to provide context for grazing data Member Company Response: n/a Environmental enrichments: Describe practices taken to ensure animals can act out natural behaviors, such as providing straw for pigs to root in, chicken perches, etc. Member Company Response: n/a HANDLING & SLAUGHTER Livestock and Poultry - % of livestock and poultry slaughter plants that are rated as “Excellent” following a third-party audit using American Meat Institute guidelines (Grandin, 2007). Member Company Response: n/a Poultry - % of poultry slaughtered using controlled atmosphere killing and transport to slaughter. Member Company Response: n/a Narrative: Describe methods and practices undertaken to ensure humane practices and reduce stress in this process. Member Company Response: n/a TRANSPORT Duration - average number of continuous hours/trip livestock and poultry are transported (load to unload). Member Company Response: n/a Downed animals - is transport of downed animals prohibited? - What are the policies for hospital, quarantine, euthanasia? Member Company Response: n/a CERTIFICATIONS CORE GOALS CORE List humane treatment certifications from animal products purchased/produced. Member Company Response: n/a Please state any numeric improvement goals for animal care 34 Member Company Response: n/a 10. SUSTAINABILITY EDUCATION (INTERNAL & EXTERNAL, includes organic aspects) Narrative Description All employees receive sustainability training in the following areas: general sustainability awareness, Green Office Program training for those who work in an office environment and the company’s Employee Incentive Program for recycling, green ideas, green home upgrades, and alternative commuting. This training is provided in the form of meetings with the Sustainability Manager and the use of PowerPoint, training forms, and informational brochures on the various program elements. Annual refresher training is scheduled to take place for all employees. Overall, employees will receive 2-3 hours of sustainability training annually, depending on their job function and involvement with sustainability related projects. Turtle Mountain’s internal newsletter, published semi-monthly, is also used as a vehicle to communicate and educate employees on sustainability initiatives. SUSTAINABILITY EDUCATION METRICS & INDICATORS EXTERNAL COMMUNICATIONS & EDUCATION Practices: Provide a narrative describing external communications, marketing and education materials, and efforts around organic and sustainable business practices, reaching business customers, vendors, consumers, media and other external audiences. Provide links to any related web pages, social media, etc., including any improvements made since your last report, if applicable, and descriptive goals. Member Company Response: In June of this year we added a sustainability page to our consumerfacing website (http://www.sodeliciousdairyfree.com/sustainability) that addresses issues such as water conservation, environmental footprint, sourcing the globe, manufacturing, and our sustainability-related memberships. We post regularly on Facebook regarding our environmental & socially-minded efforts (www.facebook.com/sodeliciousdairyfree). In addition, we have developed marketing PPT slides for our sales & marketing team that address organic agriculture and other sustainability-related items. INTERNAL COMMUNICATIONS & EDUCATION Practices: Provide a narrative on internal communications, education and training, and materials CORE around organic and sustainable business practices, reaching employees, board members and other internal audiences, including any improvements made since your last report, if applicable, and descriptive goals Member Company Response: Internal sustainability training is coordinated for all new hires through our HR department. Our company newsletter has a section on sustainability that is usually both CORE 35 informative and educational. We have large photos around our offices that educate employees on our partnership with the Bonneville Environmental foundation. We have additional employee training for our Green Office Program for such things as alternative commuting options, composting office organics, recycling in breakrooms, and tips for using less printer paper. Board members and senior leadership team members are kept informed via tracking of our key performance indicators which includes one aspect of sustainability. LABELING Certifications: List relevant certifications and labels you display on you products and state how you communicate their meaning (GRI PR 6) Member Company Response: USDA Organic – Products that are either certified “Organic” or “made with organic [ingredient(s)]” are displayed front-of-pack with additional information on our website on why organic matters. Non-GMO Project Verified – displayed front-of-pack on all certified products Recyclable/Recycled materials – displayed on a side panel, indicating whether the package contains recycled material and if/where it can be recycled as applicable. TRAINING CORE Annual Average Workplace Sustainability training (hours) - hours per employee per year Describe training activities and any evaluation for understanding and application Describe how you prioritize and tailor information to key groups Member Company Response: Office employees typically receive a minimum of one hour of training per year, whereas production employees will receive 2-3 hours, depending on their specific job duties. Most trainings are via PPT presentations and there is typically time reserved at the end for Q&A. Information is tailored to each group based on their respective jobs within the company: office employees interface with our Green Office Program; and production employees are trained on content such as water conservation, employee incentive program, and scrap reduction. GOALS CORE Please state any numeric improvement goals for sustainability education. Member Company Response: no specific goals identified currently 11. GOVERNANCE AND COMMUNITY ENGAGEMENT 36 Narrative Description Our sustainability program is based on a company-wide desire to both minimize environmental impact and be a socially responsible corporate citizen. To meet these goals, Turtle Mountain has established programs, procedures and policies to ensure the company delivers on these commitments. The cornerstones of the sustainability program are the eleven action areas, a sustainability task force, life cycle analysis, employee initiatives, community involvement, green technology, and strengthening the brand value of So Delicious Dairy Free. Continuous improvement and transparency are hallmarks of all program areas. GOVERNANCE AND COMMUNITY ENGAGEMENT METRICS & INDICATORS SUSTAINABILITY GOVERNANCE Sustainability Measurement and Reporting. (GRI 3.3, 3.5, 3.9), CORE Provide a narrative on the processes used to gather and verify sustainability reporting data, develop annual sustainability reports and communicate results Member Company Response: data collection and processing is coordinated by the Sustainability Manager and involves several other departments including Accounts Receivable, Accounting, HR, and Purchasing. Each of these departments reports either monthly or annually on required data and the Sustainability Manager is responsible for collecting and processing this data in Spreadsheets. Sustainability Management: Provide a narrative on how you manage your sustainability program CORE (strategy, goal setting, implementation, etc) (GRI 4.1) Member Company Response: Sustainability is managed in alignment with our company’s six longterm strategic priorities. Specifically, sustainability aligns with building one strong brand, optimizing product growth, improve margins, and build best-in-class organization. From there, sustainability goals and objectives are set annually and managed through 90-day priority metrics & systems. Gantt Charts are utilized to track various projects and regular presentation decks are prepared to ensure vertical alignment with senior management. BUSINESS GOVERNANCE Governance: Provide a narrative describing your company’s governance including structure, CORE ownership, independent board, etc. (GRI 4, Governance) Member Company Response: The Company is structured as a Limited Liability Corporation, with a board of directors that guides senior management strategy and performance results. Our leadership team consists of Mark Brawerman CEO (company founder and former president), John Tucker – President, Mike Duntement – VP Operations, Kevin Brouillette – VP Sales, Michael Murray – VP Marketing, and Bob Piercey – CFO. The Sustainability Manager reports to the VP of Marketing. Does your company have a policy or standards governing ethical conduct? If so, specify and/or provide document or URL (GRI 4.8) Member Company Response: No information currently available 37 TRANSPARENCY & STAKEHOLDER ENGAGEMENT Policies & Practices: Describe company policy on ensuring transparency around practices & products, and efforts related to engaging internal and external stakeholders to assess and business practices and products, particularly with regard to sustainability efforts. (GRI 4.14-16) Member Company Response: While we do not yet have a formalized program to allow 3rd party certifiers or auditors to assess our sustainability practices this is an area of ongoing discussion that we hope to improve upon in the coming year. Our current approach is to engage consumers through social media and our website to drive discussions around transparency and related sustainability issues. COMMUNITY ENGAGEMENT Practices: Provide a narrative describing your company’s community engagement programs, including CORE charitable contributions, employee volunteerism, board service, stakeholder relations, etc. Note any focus areas, key partners, workplace programs (e.g., matching employee donations and volunteerism). Member Company Response: Charitable contributions involving cash donations include the Sea Turtle Restoration Project, Farm Sanctuary, and the McKenzie River Trust. The Company also donates food products to various other non-profits such as Food for Lane County, Susan G. Comen Foundation, Farm Sanctuary, etc. The Company has an employee volunteerism program that allows 8 hours of paid volunteerism work per annum. The company is actively involved in local Chamber of Commerce activities and recently won the Emerald Award for Growth. CORE Charitable Contributions – Dollar value of all financial and in-kind charitable donations made in the past year and what % of net sales this represents. Separate in-kind and financial when reporting dollar value. (GRI EC 1) Member Company Response: in-kind donations: $95,000 (0.15% net sales) and $13,056 financial giving (0.02% net sales). Employee Volunteerism - total hours employees volunteer on the clock and off the clock, and average hours per employee Member Company Response: data not currently available ADDITIONAL THIRD PARTY CERTIFICATIONS AND RECOGNITIONS Certifications: List All Current Third Party Certifications not referenced in above sections (GRI 4.12) Member Company Response: Certified RE-Think business through Bring Recycling for the company’s Green Office Program BRC-certified food operations Awards: List awards and recognitions received in the past 5 years, related to any of the 11 Declaration 38 Areas and the practices covered in these metrics (GRI 2.10) Member Company Response: Achievement Award – Farm Sanctuary RE-Think certified business – Bring Recycling GOALS CORE Please state any numeric improvement goals for governance and community engagement. Member Company Response: goals are presently qualitative. 39