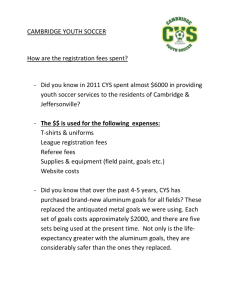

Recycled aluminum can also be used in applications where it

advertisement

Session A11 2246 RECYCLED ALUMINUM IN MODERN INFRASTRUCTURE Jim Brucker (jrb172@pitt.edu), Rob Gehris (rsg31@pitt.edu) Abstract— Currently, humans are dealing with the issue of using resources faster than the Earth can produce them. As a result, there has been a significant push in recent years toward “green” technology, processes which minimize negative effects of production processes on natural systems on Earth. This paper will delve into the uses and composition of recycled aluminum. We will describe the uses for aluminum in military, infrastructure and construction, as well as the technology used to create each of these applications. We will also discuss the implications of “green technology.” This paper’s main focus is on recycled aluminum, a “green” technology. In order to be considered “green,” a product is expected to have a minimal environmental impact. One of the key measurements in this facet is the concept of embodied carbon, or the amount of carbon dioxide associated with the production of a material. A crucial part of civil engineering is the materials used in applications. Recycled building materials are used regularly, and the military uses recycled plastics in a majority of their bridges. Recently, more and more facets of infrastructure have been built with the green movement in mind, and recycled aluminum is a key component of this movement. This paper discusses how the recycled aluminum process works, as well as the physical and environmental properties the product provides. As modern consumers demand more environmentally conscious technology, engineers must be able to meet these demands. The widespread use of recycled aluminum is the first step. Key Words—Aluminum Composites, Embodied Carbon, Recycled Aluminum, Recycled Dross, Salt Flux, Virgin Aluminum. MODERN VIEW ON ALUMINUM Imagine a soda can. It’s about six inches tall, three inches wide, filled with fizzy drink, and made out of aluminum. That’s all it is, just your average, every day, run-of-the-mill soda storage container. A can. Now imagine a building. Not just any building though, a two-hundred foot tall behemoth of modern construction, built to withstand earthquakes, whipping winds, and just about everything else that Mother Nature can throw at it. Now picture a metal baseball bat, or a computer, fighter jet, car or a boat. Maybe even picture a spaceship. What do these objects and a plethora of others have in common? The basic material used to make them: aluminum. University of Pittsburgh Swanson School of Engineering Aluminum (or aluminium for users of the metric system), is one of the most versatile metals thanks to its structural properties which make it relatively lightweight, strong, sturdy, and, most importantly, completely recyclable. This last property is what make this element so amazing, and is the topic of this paper. This paper will delve into the uses and composition of recycled aluminum. It will describe the uses for aluminum in business, infrastructure and construction, as well as the technology used to create each of these applications. We will also discuss what the term “green technology” means. Due to its high reactivity, aluminum is never found in its pure elemental form in nature. Virgin aluminum is extracted from bauxite ore and processed from there. The bauxite is mined out of the ground in large geological formations. The combination of all these processes to make useable aluminum makes virgin aluminum a very inefficient metal. However, aluminum’s ability to be completely recycled more than makes up for this high initial energy toll, as the energy to recycle aluminum is much less than the energy toll to produce virgin aluminum. The degree of exactly how much less energy will be discussed later into the paper. WHAT IT MEANS TO BE “GREEN” If a technology is considered “green,” it is commonly understood that this technology is meant to be environmentally friendly. However, this is where the misconceptions start: what does environmentally friendly mean? Does it have no environmental affects, or positive environmental affects? Clearly, there is a grey area in the common definition. There was no standard definition of “green” until Underwriters Laboratories (UL) Environment started evaluating products being marketed as eco-friendly, environmentally friendly, and “green.” UL has been ensuring the safety of household electronics for 115 years [1], proving that they are the right company for this job. As part of their verification of green products, UL requires manufacturers to test the products to obtain an Energy Efficiency Certification, an Environmental Claims Validation, and a Sustainable Product Certification [1]. Companies want validation from UL Environment for one main purpose: environmentally green products tend to make companies financially green. The word “green” is often used to sell products. Most middle-class citizens are willing to spend a few extra cents April 14, 2012 Brucker Gehris on a purchase if they feel like they are doing a good deed for the environment. The current trend throughout most of the developed world is for products and processes to be sustainable. Most people will equate sustainability and greenness. It is the common belief that a product labeled as “green” is a good product [2]. According to Tristan Roberts, a columnist for the Brattleboro Reformer, this “green equals good” mentality is driven by the media, and generally tend to be true. However, this is not the case for all products, which is why UL Environment provides validation. So, instead of looking for the word “green,” consumers should look for the UL stamp of approval, Figure 1. removed using a chlorine flux [3]. During the addition of flux, aluminum dross becomes a by-product of the aluminum and the impurities. This dross is then crushed, filtered through a screen, and then melted in a rotary furnace. The aluminum from the dross is collected at the bottom of the furnace and melted in with the rest of the pure molten aluminum [3]. The molten aluminum is then ready to be shaped into whatever shape it needs to be for it to be useable for consumers. This type of aluminum smelting process – one of a couple of d different styles of processing and refining the metal – is the version preferred and outlined by the Illinois Sustainable Technology Center at the University of Illinois. SALINE FLUX FIGURE 1 THE UL STAMP OF APPROVAL FOR SUSTAINABLE PRODUCTS [1] How can one measure the environmental friendliness (or “greenness”) of recycled aluminum? The product itself doesn’t emit gases or have any inherent side-effects on the environment. One has to look at the production process. The industry standard is to look at the embodied carbon of a material. The embodied carbon of a product is measured with an estimation of the amount of carbon dioxide, in kilograms, associated with the production of one kilogram of the material [2]. The embodied carbon of recycled material tends to be much lower than the embodied carbon of virgin material. This difference is incredibly noticeable in recycled aluminum, as will be shown in the next section. TECHNOLOGY INVOLVED When one thinks of recycled aluminum, the simplest thought is to imagine tossing an aluminum soda can into the recycling bin and letting other people turn it into another can. But how does that one can become a new can? Better yet, how does that can turn into an aluminum bar used to build a house, a bridge, or even a skyscraper? The simple answer is that this process happens in an aluminum recycling plant. What happens inside the plant though, is more complicated. There are multiple processes used to recycle aluminum; however, most plants use either one of or both of the standard processes – saline flux technology and recovery of dross. Prior to these specific technologies, aluminum scrap is normally melted in a gas or oil fueled hearth furnace. It is at this point in the process where impurities are University of Pittsburgh Swanson School of Engineering Saline (salt) flux is used in the melting of aluminum to filter out impurities. Its main function is to become a barrier of sorts between the molten aluminum and the oxygen in the atmosphere of the furnace in order to, according to the Handbook of Aluminum by George Totten and Scott MacKenzie, diminish the oxidation of the top layer of aluminum [4]. The salt flux also helps to remove the topmost oxide layer which is sometimes formed in previous stages in the melting process. As it has very specific tasks, the salt fluxes must have certain characteristics. The flux must have a melting point below the heat of the furnace – around 720OC – and have a low viscosity and vapor pressure at this temperature. The flux cannot react with the molten aluminum; if it did, it would add impurities to the metal, risking its structural integrity. In the same vain as not reacting with the metal, the fluxes must be easily detachable from the liquid bath and able to be reused in future melting of aluminum [4]. Several compounds have the properties needed to make a good salt flux for melting down recycled aluminum. The least expensive tend to be mixtures of sodium chloride (NaCl) and potassium chloride (KCL), normally in a one to one molar ratio mixture. To help create the barrier between the aluminum and the oxygen, several fluorides are added to the mix. The common fluorides are cryolite [5] (Na 3AlF6), sodium fluoride (NaF), potassium fluoride (KF), calcium fluoride (CaF2), and Magnesium Fluoride (MgF2) [4]. There are methods of protecting the aluminum from forming oxides other than saline fluxes. The most prominent of these technologies is the replacement of fossil fuels heating the rotary furnace with plasma torch treatment [3]. Higher concentrations of aluminum are recovered using this technique; however, the plasma torch treatment does not April 14, 2012 Brucker Gehris make sense economically, as it costs significantly more than basic fossil fuels, and the aluminum output is not significantly larger. Some aluminum melting plants prefer this technology though because of the oddities that occurs in the aluminum with the use of the salt fluxes. These oddities include the formation of dross and saltcakes, as well as fumes from the burning of fossil fuels [4]. The plasma treatment generates some fumes, but significantly less than the fossil fuel driven furnaces. ALUMINUM DROSS RECOVERY Dross is a consequence of the melting of aluminum. It is formed on top of the molten aluminum as it reacts with the atmosphere in the furnace. In general, “15-25 kilograms of dross are produced per metric ton of molten aluminum” [4]. The three types of dross are white dross, black dross, and saltcake. Each step in the metallurgy of aluminum produces a different classification of dross. White dross comes from the primary step in the refinement of recycled aluminum. This step includes the extrusion and lamination plant, and melting the processed aluminum in foundries. White dross will contain anywhere from 15% to 70% of aluminum [4], giving it a light gray color, hence the name “white” dross. Black dross is a byproduct of the secondary metallurgy of the recycled aluminum. This step in the process uses the saline flux technology mentioned above. Black dross contains significantly less aluminum than white dross, causing it to have a darker color. Saltcake is produced from the aluminum recovered from the white and black dross. It has a very high salt concentration and a darkish hue. Saltcake contains 1% to 7% of aluminum [4]. There is not much difference between the saltcake and the black dross. The combination of white dross, black dross, and saltcake is then treated and the recovered aluminum is added to the recycled material. Aluminum is extracted from the dross in rotary furnaces in which salts are added to increase the quantity of aluminum recovered [4]. ADVANTAGES OF RECYCLED ALUMINUM VERSUS VIRGIN ALUMINUM As previously mentioned, the industry standard of measuring eco-friendliness, or “greenness,” is with the measurement of the embodied carbon of the product. Using this as a scale, recycled aluminum is much greener than virgin aluminum. In a study referenced by Tristan Roberts in his article “Recycled is Good… Right?” the average embodied carbon associated with new aluminum is 12.79 kg CO2 while the average embodied carbon of recycled aluminum is only 1.81 University of Pittsburgh Swanson School of Engineering kg CO2 [2]. This equates to about 95% less energy being used to produce recycled aluminum than used in producing virgin aluminum. Recycled aluminum also produces about 95% less pollution than virgin aluminum in its production process [6]. As well as being significantly greener, recycled aluminum has comparable structural strength as the virgin material. Less than 1% of aluminum’s structural ions are lost in the recycling process, making it close to infinitely recyclable with structural strength that barely deteriorates from the initial strength of the virgin material [3]. This means that recycled aluminum has the same properties as virgin aluminum for less cost, financially and environmentally. Also, as previously mentioned, virgin aluminum comes from bauxite which comes from mines close to the Earth’s surface. While there is plenty of bauxite down there, it is still a nonrenewable resource, and there is a limited amount. Additionally, bauxite mines take up large amount of space and are very destructive to the environment around them. Recycling aluminum can reduce the amount of mining, aiding in the effort to reduce the environmental impact of this product. BUILDING AND CONSTRUCTION While the technologies and processes behind the production of recycled aluminum certainly are important, without an effective way to apply this material to real-world applications the production is pointless. We will discuss specifically how recycled aluminum can be used both used in and obtained from infrastructure and how it to useful to the modern day building and construction industry. One reason recycled aluminum should be used more in industry today is because of how easily it can be recovered after demolition processes. Based on a study in European study that looked at nine different types of buildings in six different countries, it was found that the average aluminum collection rate after demolition was 95.7% [7].Even though the content of aluminum in these buildings was less than 1%, a substantial amount was able to be recovered for recycling [7]. As we discussed earlier, sustainability is a key idea in industry today. Not only can aluminum be used in the production of buildings, but when it comes time for those buildings to be demolished nearly all of the aluminum used can be submitted for recycling and reused in further building and construction applications. A crucial concern when using this recycled aluminum in construction is whether or not it is strong enough to withstand stresses as a part of a building application. When April 14, 2012 Brucker Gehris recycled aluminum is taken recovered from building demolition, it is split into two categories. Nearly equal amounts of sheet products and extruded shapes, which correspond to 5xxx and 6xxx alloys respectively, remain after aluminum is recovered [7]. If these all alloys are presorted during demolition, composites can be easily made and directly reused in building and construction applications without a significant loss of structural strength [7]. This is of importance because it demonstrates the valuable benefits of the use, and subsequent reuse, of aluminum in building and construction applications. By simply sorting different aluminum alloys in an appropriate manner, it is possible to directly reapply the material to other building and construction applications without much complication. This is a major advantage over the use of unrecycled material, which requires more complicated and arduous production. The actual applications for recycled aluminum vary greatly. While recycled aluminum typically is not the main component of a structure, it still plays a major role in building and construction. For instance the main structure of a bridge may be made of steel, but, as suggested by the Aluminum Extruders Council, recycled aluminum can be effectively used for the deck of the bridge [8]. This can be seen with the Corbin Bridge located in Pennsylvania, which originally had a deck made out of steel and timber. After being refurbished with an extruded aluminum deck, the carrying capacity of the bridge increased from seven to twenty-two tons [8]. This shows that while aluminum may not be the main element of this bridge, its use in the deck of the bridge can still have a major impact by improving the strength of the structure. The fact that recycled aluminum has the ability to improve facets of infrastructure while exhibiting green characteristics is a major reason why its widespread use would be beneficial. Another prime example of the use of recycled aluminum in building and construction is the Mirabella Portland, a retirement community located in Portland, Oregon. Aluminum was used for railing, trellis, and canopy parts, reducing the risk for onsite injury as well as increasing the speed of the instillation [8]. The project earned Leadership in Energy and Environmental Design (LEED) Platinum certification, largely due to the use of 25-percent recycled aluminum [8]. The Mirabella Portland demonstrates the myriad of possible uses for recycled aluminum in building and construction design in addition to making construction safer and more efficient. The recognition of LEED, a highly respected organization, legitimizes the effectiveness and positive impact of recycled aluminum in building and construction. University of Pittsburgh Swanson School of Engineering MILITARY APPLICATIONS Recycled materials, specifically aluminum, have a place in military usage as well. The military has already shown a willingness to make the switch to recycled materials in order to improve efficiency and performance. This is demonstrated by plans to construct two railroad bridges made out of nearly one hundred percent recycled material at Fort Eustis, Virginia, the home of the US Army Transportation Corps [9]. These bridges are set to be built using a material known as Recycled Structural Composite, or RSC, more quickly and less expensively than with materials such as concrete or steel [9]. The usage of recycled composites by the military is a very encouraging sign. By using RSC in construction, the military is recognizing the importance and effectiveness of recycled materials in construction applications and showing openness to further use. Perhaps most importantly, the use of recycled materials in the military is a sign to other sectors of industry that recycled materials can be just as effective as, if not superior, to their non-recycled counterparts. This reassurance from an entity as trusted and respected such as that of the US military can be a key factor to the further incorporation of recycled materials in society today. Aluminum has proven time and time again to be of great use in US military applications. In fact, its use goes back as far as 1892, when it was a key component in military torpedo boats [10]. An important military use for aluminum is for armor, specifically on combat vehicles. Aluminum offers advantages over other materials like steel for this application because of its light weight, rigidity, and temperature tolerance [10]. The use of aluminum in many different types of vehicles is actually quite common. Aluminum is used in the production of everything from general purpose vehicles to amphibious combat vehicles [10]. Almost everything on these vehicles is made at least in part with aluminum, including the wheels, frame, and turbo shaft engines [10]. Another military application of aluminum is in the production of firearms and projectiles. According to “Aluminum Alloys in Vehicles and Equipment,” aluminum has been used to make ammunition and torpedo shells, as well as components in the production of firearms, such as the M-16, M-60 machine gun, and the M-72 recoilless rocket launder [10]. Aluminum’s low cost, as well as light weight, are the major advantages for these particular applications. The low weight of aluminum is especially important for this application because for soldiers the reduction of carrying weight can make a big difference. Much of the aluminum April 14, 2012 Brucker Gehris used in military applications comes from the 5xxx alloy [10]. As stated previously, the 5xxx alloy can be made almost entirely from recycled materials without losing anything in the way of strength or other properties. Because all of the ways aluminum can be used in military applications, an increase in recycled aluminum utilizations would have quite an impact in increasing efficiency, reducing cost, and improving renewability for the US military and the country as a whole. ADVANTAGES OF ALUMINUM OVER COMMON CONSTRUCTION MATERIALS Naturally, every material used in construction has a specific task: concrete makes a great foundation, fiberglass makes for great insulation. However, there are many structural aspects of construction can be replaced by better materials. Just as steel replaced timber as the main structural aspect of modern buildings, aluminum can replace multiple facets of architecture. As stated in an article on the website for The Metal Initiative, aluminum is very malleable and ductile, allowing it to be formed into a multitude of profiles and shapes [11]. This property makes aluminum easy to use as panels, siding, and shingling. This last one, shingling, is where aluminum truly shines (literally). Aluminum roofing provides a large degree of radiant heat reflectivity, regardless of the slope of the roof. This ability to reflect solar light results in less heat transfer to the building during the summer, lowering energy costs to keep the building cool [11]. Additionally, aluminum panels require fewer joints than other paneling materials, providing for quick and economical installation. Attaching aluminum panels to a building is one of the quickest parts of building construction, and one of the most important for the building to be energy efficient and aesthetically pleasing. Aluminum is not limited to being used as simple panels in construction. Since it is so malleable, aluminum can be used as lightweight aesthetic portions of buildings with, as will be discussed later, very little maintenance work needed. Due to its relatively low weight, aluminum can also be retrofitted onto older buildings, either for functionality, replacement necessity, or even just for the sake of the building looking good [11]. Additionally, aluminum alloys are very corrosion-resistant. For the majority of cases in which aluminum is used in construction, aluminum does not need protective finishes, unlike other common materials such as steel or copper. Recycled aluminum can also be used in applications where it improves energy efficiency. Because of its high strength to weight ratio, as shown in Figure 2, ability to accept high-grade paint finish, and exceptional heat qualities, extruded aluminum is an ideal material for the panels of high-rise buildings [8]. Windows made of FIGURE 2 STRENGTH TO WEIGHT RATIOS OF VARIOUS METALS [14]. University of Pittsburgh Swanson School of Engineering April 14, 2012 Brucker Gehris aluminum are also highly efficient due to favorable heating properties. Once again, aluminum is shown to be a versatile material with many favorable construction properties. Perhaps most importantly, recycled aluminum is a material that is able to perform at a high level with minimal maintenance, a key factor when looking at building and construction applications. Aluminum does not absorb moisture, cannot rust, and its properties are unaffected by weather and time [8]. In the case of aluminum windows with a weather seal, the only maintenance required is a cleaning with a wet cloth to maintain aesthetic value. The ability for aluminum to be used in so many different applications certainly makes an increased focus in the production and usage of recycled aluminum attractive. Not only does it have the potential to be energy efficient and make industry more green; it also has the ability to be extremely efficient and cost effective, an important concern in industry today. USES IN BUSINESS When making the decision on what materials to use in building and construction applications many factors play a role. Everything from environmental factors to the visual appeal of a material factors into the decision. However, with today’s economic climate, the financial aspect of a project moves to the top of the list in importance. Firstly, the production of recycled aluminum is much more energy efficient than making aluminum from scratch. As previously stated in this paper and further confirmed by The Aluminum Association, it takes 95 percent less energy to produce aluminum from recycled materials than it does to produce it from aluminum ore in bauxite [12]. The cost benefit of using recycled material above production of new aluminum is quite clear based on this data; the less energy put into a process the more money is saved. The cost effectiveness of recycled aluminum is favorable when compared to other recycled materials as well. One ton of recycled aluminum can lead to $1,000 in revenue, which is five times more than that of steel [12]. This revenue is also compounded with the energy – and money – saved in recycling aluminum compared to other materials, making aluminum even more economically beneficial. Such extreme economic benefits are hard to ignore. Not only is the use of recycled aluminum environmentally friendly, but it is able to be extremely monetarily beneficial as well. Aluminum production would not only be favorable because of the energy efficiency, but also because of the percent of the metals markets that it occupies. As discussed University of Pittsburgh Swanson School of Engineering in “Recyclable Aluminum Rolled Products: Building Blocks for a Sustainable World”, by John Green and Michael Skillingberg, production of aluminum takes up close to 50% of the metals market in North America [13]. To increase the widespread use of aluminum would lead to a boom in an already affluent industry, creating more jobs, better jobs, and more profit. 60% of the aluminum production (that’s 30% of the total market), comes from the recycling of aluminum. Traditionally in North America, the trend has been an increase in the tendency to rely on mostly recycled or imported material [13]. Recycling aluminum would increase the recycling aspect of this tendency, helping to reduce the reliance on imported material In fact, the importance of recycled aluminum is not just limited to the scope of one particular corporation of industry; it has a large impact on the American economy as a whole. It is the largest component of domestic metal supply and minimizes the need for imported metals. An increase in recycled aluminum can collection of just one percent corresponds to savings of twelve million dollars. Additionally, recycling aluminum aids in the recycling of other materials. Aluminum is one of the few products that, when recycled, generates profit. Steel, glass, plastics, and paper all have an average collection cost of $200 per ton, and resale of the newly recycled products is nowhere close to covering the collection cost [12]. Luckily though the recycling of aluminum is very profitable, as previously mentioned, and can often make up for the loss in revenue of recycling the other products. If a company intends on recycling paper, steel, and plastics, it can easily keep producing profits and stay in the black by recycling aluminum. It is very clear that the financial benefits of recycled aluminum are astronomical and are one of the main reasons it is a process that should be looked into further and expanded. SUMMARY The most prevalent method of recycling aluminum was outlined in order to demonstrate the ease at which it is done. In addition to basic smelting, other processes were illustrated. The salt flux is added to molten aluminum to keep the molten aluminum free of oxides. Dross and saltcake are collected after the fact to maximize the amount of aluminum collected from the process. The result is aluminum which is nearly identical to the original virgin product. April 14, 2012 Brucker Gehris The use of aluminum in industry was outlined in order to show its versatility. Aluminum can be used in construction for roofing, siding, and basic exterior or interior components of buildings and other structures. The advantages of aluminum over other various construction materials were also outlined to further show its versatility. Finally, the cost effectiveness of aluminum was discussed in order to show the role recycled aluminum has in business. Recycling of aluminum is profitable enough to keep all of the recycling industry afloat in a down market and still allow corporations which rely on aluminum to keep a profit. CONCLUSION It is the purpose of civil engineers to solve the problems that the world will present. The two largest problems facing the Earth as a whole are depletion of natural resources and the struggle for the Earth to keep up with a constantly increasing amount of human beings. As the human population continues to increase, a greater need for improved infrastructure will be highlighted. It is the job of engineers of all disciplines, especially those in the fields of civil engineering and materials engineering, to make these improvements happen. This problem must be solved with methods that reduce the depletion of our natural resources. The answer to both of these issues can be found in the field of recycled aluminum thanks to its value as a sustainable product and its assets as a solid construction material. This should, if nothing else, stress the importance of recycled aluminum in modern infrastructure. . University of Pittsburgh Swanson School of Engineering April 14, 2012 Brucker Gehris REFERENCES ACKNOWLEDGEMENTS [1]“UL Environment.” UL Environment. N.p., n.d. Web. 25 Feb. 2012. http://www.ulenvironment.com/ulenvironment/eng/pages/ [2] Roberts, Tristan (2011, June 28). “Recycled is good…right?” Brattleboro Reformer. [Online]. http://www.lexisnexis.com/hottopics/lnacademic/?shr=t&csi= 279934&sr=HLEAD(Recycled+is+good+...+right%3F)+and+ date+is+June,%202011 [3] “Aluminum Smelting and Refining.” Illinois Sustainable Technology Center – University of Illinois. N.p., nd. Web. 25 Feb. 2012. http://www.istc.illinois.edu/info/library_docs/manuals/primme tals/chapter4.htm [4] Totten, George E., and D. Scott MacKenzie. "Handbook of Aluminum: Alloy production and materials manufacturing George E. Totten, D. Scott MacKenzie - Google Books." Google Books. N.p., n.d. Web. 7 Feb. 2012. http://books.google.com/books?id=XlmAKOjvnrgC&pg=PA1 26&lpg=PA126&dq=salt+flux+aluminum&source=bl&ots=2 wG9poC3iR&sig=YRFViA3MWaNjslQHD6OkhJzvCEQ&hl =en&sa=X&ei=KO0xT_auC6fF0AHo15DhBw&ved=0CEQQ 6AEwAw#v=onepage&q=salt%20flux%20aluminum&f=false [5] “Cryolite Mineral Data.” Mineralogy Database. N.p., n.d. Web/ 25 Feb. 2012. http://webmineral.com/data/Cryolite.shtml [6] "Energy Costs and Conservation Facts." Earth911.com. N.p., n.d. Web. 26 Feb. 2012. http://earth911.com/reduce/energycosts-and-conservation-facts/ [7] S. Das, J. Green, J.Kaufman, D. Emadi and M.Mahfoud. (2010, February). “Aluminum recycling—An integrated, industrywide approach” JOM Journal of the Minerals, Metals, and Materials Society.” [Online]. Available: http://www.springerlink.com/content/v05603g818360260/ [8] “Market Sectors: Building and Construction.” Aluminum Extruders Council. N.p., n.d. Web. 26 Feb. 2012 http://www.aec.org/exapps/building.html [9] “Army to buy railroad bridges made from recycled plastic.” Noria Corporation. N.p, nd. Web 1 Mar. 2012 http://www.reliableplant.com/Read/21362/army-to-buyrailroad-bridges-made-from-recycled-plastic [10] “Aluminum Alloys in Military Vehicles and Equipment.” (2010). Keys to Metals. [Online], Available: http://www.keytometals.com/Article102.htm [12] “Aluminum in Commercial Construction.” The Metal Intiative. N.p., 2010. Web. 28 Feb. 2012. http://www.themetalinitiative.com/content/building_with_met al/types_of_metal/aluminum.cfm [12] “Aluminum.” The Aluminum Association. N.p., n.d. Web. 26 Feb. 2012. http://www.aluminum.org/Content/NavigationMenu/NewsStat istics/Sustainability/default.htm [13] Green, John, and Michael Skillingberg. “Recyclable Aluminum Rolled Products: Building Blocks for a Sustainable World.” Light Metal Age. N.p., Aug 2006. Web. 26 Feb. 2012 http://www.aluminum.org/Content/NavigationMenu/TheIndus try/SheetPlate/RecyclableAluminumRolledProducts/Skillingb ergAug06.pdf [14] “Strength to weight ratio aluminum – Google Search.” Google. N.p., n.d. Web 1 Mar. 2012 University of Pittsburgh Swanson School of Engineering April 14, 2012