useful machine

advertisement

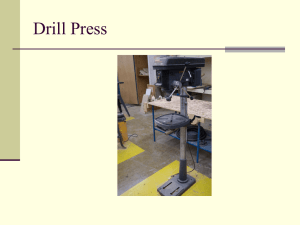

1 UNIT-4 DRILLING AND BORING MACHINES Introduction: The drilling machine or drill press is one of the most common and useful machine employed in industry for producing forming and finishing holes in a workpiece. The unit essentially consists of: 1. A spindle which turns the tool (called drill) which can be advanced in the workpiece either automatically or by hand. 2. A work table which holds the workpiece rigidly in position. WORKING PRINCIPLE OF DRILLING:Drilling is the process (operation) of making holes in a solid metal (workpiece) by means of a rotating cutting tool called drill. It is one of the most common operations in the manufacturing industry. In this operation can’t produce a perfectly true hole. It is considered as a roughing operation. So drill is followed by another operation called reaming. In reaming operation the required dimensional accuracy & fine surface finish is obtained means of a multi tooth revolving tool called reamer. In this, the workpiece is held stationary during the process. Main parts of the drilling machine:- 2 The main operating parts of a sensitive machine/drill press are Base, Column, Table, and Drill Head. 1. Base: The base is a heavy casting that supports the machine structure; it provides rigid mounting for the column and stability for the machine. The base is usually provided with holes and slots which help to Bolt the base to a table or bench and allow the work-holding device or the workpiece to be fastened to the base. 2. Column: The column is a vertical post that Column holds the worktable and the head containing the driving mechanism. The column may be of round or box section. 3. Table: The table, either rectangular or round. Drill machine/press in shape supports the workpiece and is carried by the vertical column. The surface of the table is 90-degree to the column and it can be raised, lowered and swiveled around it. The table can be clamp/hold the required the workpiece. Slots are provided in most tables to allow the jigs, fixtures or large workpieces to be securely fixed directly to the table. 4. Drilling Head: The drilling head, mounted close to the top of the column, houses the driving arrangement and variable speed pulleys. These units transmit rotary motion at different speeds to the drill spindle. The hand feed lever is used to control the vertical movement of the spindle sleeve and the cutting tool. Specifications of drilling :According to ‘Indian standards’ the drills are specified by their diameters, materials…etc. these data are mainly based on the material for which the drill is to the normally used. They are made in 3 types: 1. Type N- For normal low carbon steels, 2. Type H - For hard materials, and 3. Type S – For soft and tough materials. In British system there are three different ranges of sizes: 1. Normal sizes drill:The standard set of number sized drills consists of 60, numbering from 1 to 60, although against special order drills up to number 80 can also be obtained. In this series of drills higher the number smaller is the size of the drill and vice versa. 3 2. Letter sizes drill:This series of drills is designated by letters from A to Z, in which A represent the smallest size and Z the largest. In this series the drill sizes, starting from A (=0.234”), go up in the steps of about 0.01” with the largest size Z being equal to 0.413. 3. Fractional sizes drill:- In this series the drill sizes start from 1/64” and go up to 5” in diameter. Up to 1 4 the rise in sizes is uniform in steps of 1/64 and beyond this the steps are larger . Different types of drilling machines and their features:1. Portable drilling machine 2. Sensitive or bench drill 3. Upright drilling machine (single spindle) 4. Upright drilling machine (Turret type) 5. Radial drilling machine 6. Multi spindle drilling machine 7. Deep hole drilling machine. 8. Gang drilling 1. Portable drilling machine:It is a very small, compact and self-contained unit carrying a small electric motor inside. It is used for drilling holes in components that cannot be transported to the shop floor due to their size or weight or where lack of space does not permit their transportation to the bigger type of drilling machine. In such case, the operation is performed on the site by means of the portable electric drill. Portable drills are fairly light in weight so that they can be easily handled by one or two men only. 2. Sensitive or bench drill:- 4 This type of drill machine is used for very light work. It construction is very simple and so is the operation. It construction of a cast iron base having a fixed table over it. At the top of the column is provided the drive, which consists of an endless belt running over two v-pulleys one of these pulleys is mounted on the motor shaft and the other on machine spindle. No gears are used in the drive. The vertical movement to the spindle is given by the feed handle through a rack and pinion arrangement. The spindle usually caring No 1 Morse taper. These drills are normally manufactured having up to 20mm drilling capacity in steel. 3. Upright drilling machine (single spindle):It is also known as standard, vertical or pillar drilling machine. It is used for heavier work and has back hearing arrangement similar to a lathe. Specifically differs from a sensitive drill in its weight, rigidity, application of power feed and the wider range of spindle speeds. These machines are manufactured in various sizes having different drilling capacities up to a maximum of 75mm in steel. 4. Upright drilling machine (Turret type):It is a production drilling machine, which is very useful when a series of different size holes are to be drilled repeatedly or a number of different operations, like drilling, reaming, boring, spot facing….etc. are to be performed in sequence repeatedly. 5. Radial drilling machine:This machine is very useful because of its wider range of action. Its principal use is in drilling holes on such work which is difficult to be handled frequently with the use of this machine, the tool is moved to the desired position instead of moving the work to bring the latter in position for drilling. 6. Multi spindle drilling machine:- These machines are mostly used in production work and are so designed that several holes of different sizes can be drilled simultaneously. Their use facilities an increased rate of production with sufficient accuracies. In these machines two or more spindles are driven from common driving shaft through worms and worm gears or belt. 5 7. Deep hole drilling machine:- Where very long holes of relatively smaller diameter are required to be drilled these machines are used, such as in rifle barrels and long spindles. These machines can be obtained both in horizontal as well as vertical types, according to the requirement. In these machines is provided stock and a carriage. The work is mounted between these two and the carriage carries the drill, on the head stock. Side, the work is supported on a spindle, which also rotates the same as the drill is fed slowly. Special type of drills are used on these machines. In deep hole drilling operation the work rotates at high speed instead of the drill, while the drill is feed into the work at low feed. The lubricant is feed to the cutting edges of the drill under pressure in abundance. Both vertical and horizontal designs of these machines are available, but the horizontal machining are more commonly used. Applications:Deep hole drilling machines are used where very long holes of small diameter are drilled such as in rifle barrels, long spindles, hollow shafts etc. 8. Gang drilling machine:- It is nothing but a type of multiple spindle drilling machine, in which the spindles are arranged in a row. These spindles may be driven either separately or collectively. This machine is very useful when the nature of work is such that a number of operations like drilling, reaming, boring and tapping…etc. are to 6 be performed in succession on it. The table may be of stationary type or adjustable type. The work moves from one spindle to the other after each operation. The no of spindles is not limited. It depends upon the type of production that is intended to be undertaken. Commonly fore spindles are to be used. 9. Automatic drilling machine:These are production machines, arranged in series to perform a no of different operations in sequence at successive work station. The workpiece, after completion of an operation at one station, are automatically transferred to the next station for another operation. Thus, it works as a transfer lime. Different operations can be performed like drilling, reaming, boring…..etc. Tool holding devices:1. Chucks 2. Spindle 3. Sleeve 4. Socket 5. Floating holder 1. Chucks:It is the most popular and useful device for holding parallel shank drill and other small tools. It is design to hold different drills of different sizes. A sleeve or socket can hold one size of tool shank only but a chuck may be used to hold different sizes of tool shanks within a certain limit. These drill chucks have tapered shanks which are fitted into the drilling machine spindle. The drill chuck can be tightened or loosened with the help of a chuck key. During the drilling operation, the jaws of the drill chuck are forced inwards or outwards from the drill which grips the driving tool or drill. Two types of chucks are commonly used. i. Quick change chuck ii. Three-jaw self-centering chuck. 2. Spindle:Most of the drilling machines have the spindle, bored out to a standard taper to receive the taper shank of the tool. The taper in spindle is standardized to 1:20, while fitting the tool in shank is forced into the tapered hole thereby the tool is gripped by friction. 3. Sleeve:The spindle of the drill is made to hold only one size of shank. If the taper shank of the tool is smaller than the taper in the spindle hole, a taper sleeve is used. The outside taper of the sleeve conforms to the drill spindle taper and the inside taper holds the shanks of the smaller size tools or smaller sleeves. 4. Socket:Drill sockets are used to hold the tool when the tapered tool shank is longer than the spindle. Drill sockets are longer than the drill sleeves. A drill socket consists of a solid shank attached to the end of the cylindrical body. 7 5. Floating holder:When a reamer or tap needs to follow a previously drilled or bored hole, a floating holder is used. Twist drill:- Twist drill is the most widely used tool in modern drilling practice. It has two cutting edges and two helical grooves. These helical grooves are called flutes. The flutes are admit coolants and allows the chip to escape during drilling operation. Twist drill consists of a cylindrical body carrying two spiral flutes cut on it. Twist drills are usually made of high speed steel. The standard twist drill is shown below. It has two main parts 1. Body 2. Shank. The body is the cutting unit with flutes, cutting edges and drill point. Its point angle is ground to 118°. The shank is the part of drill which held in machine spindle and driven by it. So the shank which is gripped in the drill chuck or sleeve. The twist drills are classified into mainly two types: i). parallel shank twist drill, ii). Tapper shank twist drill. Advantages using twist drills are:1. The chips and cutting of the metal are automatically driven out of the hole through the flutes. 2. Cutting edges are retained in good condition for a fairly longtime, thus avoiding the frequent regrinding of the drill. 3. Heavier feeds and speeds can be employed quite safely resulting in a considerable saving of time. 4. For the same size and depth of the hole they need less power in comparison to other forms of drills. Twist drill nomenclature:Axis:It is the longitudinal centerline of the drill running through the centers of the tang and the chisel edge. Body:It is the part of the drill from its extreme point to the commencement of the neck, if present. 8 Otherwise, it is the part extending up to the commencement of the shank. Helical grooves are cut on the body of the drill. Shank:It is the part of the drill by which it is held and driven. It is found just above the body of the drill. The shank may be straight or taper. The shank of the drill can be fitted directly into the spindle or by a tool holding device. Tang:The flattened end of the taper shank is known as tang. It is meant to fit into a slot in the spindle or socket. It ensures a positive drive of the drill. Neck:It is the part of the drill, which is diametrically undercut between the body and the shank of the drill. The size of the drill is marked on the neck. Point:It is the sharpened end of the drill. It is shaped to produce lips, faces, flanks and chisel edge. 9 Lip:It is the edge formed by the intersection of flank and face. There are two lips and both of them should be of equal length. Both lips should be at the same angle of inclination with the axis (59°). Land:It is the cylindrically ground surface on the leading edges of the drill flutes adjacent to the body clearance surface. The alignment of the drill is maintained by the land. The hole is maintained straight and to the right size. Flutes:The grooves in the body of the drill are known as flutes. Flutes form the cutting edges on the point. It allows the chips to escape and make them curl. It permits the cutting fluid to reach the cutting edges. Angles:Chisel edge angle:The obtuse angle included between the chisel edge and the lip as viewed from the end of the drill. It usually ranges from 120° to 135°. Helix angle or rake angle:The helix or rake angle is the angle formed by the leading edge of the land with a plane having the axis of the drill. If the flute is straight, parallel to the drill axis, then there would be no rake. If the flute is right handed, then it is positive rake and the rake is negative if it is left handed. The usual value of rake angle is 30° or 45°. Point angle:This is the angle included between the two lips projected upon a plane parallel to the drill axis and parallel to the two cutting lips. The usual point angle is 118°. When hard alloys are drilled the value increases. Lip clearance angle:The angle formed by the flank and a plane at right angles to the drill axis. The angle is normally measured at the periphery of the drill. The lip clearance angle ranges from 12° to 15°. Drilling machine operations:Though drilling is the primary operation performed in a drilling machine, a number of similar operations are also performed on holes using different tools. The different operations that can be performed in a drilling machine are: 10 1. Drilling:- It is the main operation done on this machine. It is the operation of producing a circular hole in a solid metal by means of a revolving tool called drill. 2. Reaming:- It is the operation of finishing a hole to bring it to accurate size and have a fine surface finish. The operation is performed by means of a multi tooth tool called reamer. The operation serves to produce a straight, smooth and accuracy hole. The accuracy to be expected is within ± 0.05mm. 3. Boring:- 11 It is an operation used for enlarging a hole to bring it to the required size and have a better finish. It involves the use of an adjustable cutting tool having single cutting edge. In addition to the above objective, this operation can be used for correcting the hole location and out of roundness. The accuracy to be expected is within ± 0.125mm. 4. Counter boring:- It is the operation used for enlarging only a limited portion of the hole is called counter boring. If can be performed either by means of a double tool boring bar or a counter boring tool. 5. Counter sinking:- It is the operation used for enlarging the end of a hole to fine it a conical shape for a short distance. This is done for providing a seat for the countersunk heads of the screws, so that the lather may be finish with the main surface of the work. The standard counter sinks caring included angles of 60°, 82° or 90°. 12 6. Tapping:- It is the operation done for forming internal threads by means of the tool called tap. To perform this operation the machine should be equipped with a reversible motor or some other reversing mechanism. 7. Spot facing:- This operation is used for squaring and finishing the surface around and at the end of a hole so that the same can provide a smooth and true seat to the underside of bolt heads or collars…etc. 13 Boring Boring is the process of using a single point tool to enlarge and locate a previously made hole. Drills tend to wander or drift, thus, where greater accuracy is required, drilling is followed by boring and reaming. Classification of boring machines:Boring machines are manufactured in various different designs and sizes. They can broadly be classified into the following three types: 1. Horizontal boring machine, 2. Vertical boring machine, 3. Jig boring machine. The above three, the first two types include production machines, used in general production work, last one is a precision machine used for precision boring operations, such as jig boring. Jig boring machine:- 14 How do you calculate machining time in boring:Machining time in boring is determined by the formula, T= Where, T = Machining time in minute L = Length of the workpiece in mm A = Allowance for tool approach and exit = Feed rate, mm/rev N = Revolution of the cutter for boring in rev/min. +×