Effects of Biomass in Recirculating Aquaculture Water Heating and

Cooling Systems

by

Devin Murray

Engineering Project Submitted to the Graduate

Faculty of Rensselaer Polytechnic Institute

in Partial Fulfillment of the

Requirements for the degree of

MASTER OF ENGINEERING

Major Subject: Mechanical Engineering

Approved:

_________________________________________

Prof. Ernesto Gutierrez-Miravete, Project Adviser

Rensselaer Polytechnic Institute

Hartford, CT

December, 2014

© Copyright 2014

by

Devin Murray

All Rights Reserved

ii

CONTENTS

LIST OF TABLES ............................................................................................................. v

LIST OF FIGURES .......................................................................................................... vi

LIST OF SYMBOLS ....................................................................................................... vii

LIST OF KEYWORDS .................................................................................................... ix

ACKNOWLEDGMENT ................................................................................................... x

ABSTRACT ..................................................................................................................... xi

1. Introduction.................................................................................................................. 1

1.1

State of the Aquaculture Industry ...................................................................... 1

1.2

Types of Aquaculture ......................................................................................... 3

2. Theory and Methodology ............................................................................................ 7

2.1

Theoretical System ............................................................................................. 8

2.2

Analytical Method .............................................................................................. 9

2.2.1

Definition of System Parameters ......................................................... 11

2.2.2

General Assumptions ........................................................................... 12

2.2.3

Heat Transfer Through Side Walls ...................................................... 12

2.2.4

Free Convective Heat Transfer from Surface ...................................... 13

2.2.5

Radiation Heat Transfer from Surface ................................................. 14

2.3

Baseline Heat Loads ......................................................................................... 14

2.4

Introduction of Biomass ................................................................................... 15

2.4.1

Modeling Biomass Resistance ............................................................. 16

2.4.2

Resistance Estimate.............................................................................. 16

2.4.3

Resistance Calculation ......................................................................... 18

2.4.4

Resistance Calculation - Convection ................................................... 19

2.4.5

Resistance Calculation - Conduction ................................................... 20

2.4.6

Resistance Calculation - Consolidation ............................................... 20

2.4.7

Final Resistance ................................................................................... 21

iii

3. Results and Discussion .............................................................................................. 22

4. Conclusion ................................................................................................................. 25

5. References.................................................................................................................. 26

Appendix A - Calculations .............................................................................................. 27

iv

LIST OF TABLES

Table 1: Thermal Properties of Seafood [7] ...................................................................... 7

Table 2: Thermophysical Properties [7] & [8] ................................................................ 11

Table 3: Raceway Aquaculture System Properties .......................................................... 12

Table 4: Concentration of Tilapia in Raceway ................................................................ 16

Table 5: Number of Tilapia in the Aquaculture System .................................................. 19

v

LIST OF FIGURES

Figure 1: Aquaculture Production of Tilapia in Millions of Tons [4] ............................... 2

Figure 2: Raceway Style Tank for Recirculating Aquaculture System [3] ....................... 4

Figure 3: Density of Fish in Raceway Style Tank [3] ....................................................... 5

Figure 4: Grid Coil Heat Exchanger [6] ............................................................................ 5

Figure 5: Raceway Dimensions ......................................................................................... 8

Figure 6: Heat Transfer Between Raceway and Surroundings .......................................... 9

Figure 7: Heat Transfer Diagram – Without Biomass ..................................................... 10

Figure 8: Heat Transfer Diagram – With Biomass .......................................................... 11

Figure 9: Simplified Heat Transfer Diagram – Baseline System .................................... 15

Figure 10: Simplified Heat Transfer Diagram – Biomass System .................................. 15

Figure 11: Tilapia Model ................................................................................................. 16

Figure 12: Introduction of Nile tilapia biomass ............................................................... 19

Figure 13: Simplified Heat Transfer Diagram – Water and Tilapia ................................ 21

Figure 14: Required Heat Load vs Tilapia Concentration ............................................... 22

Figure 15: Required Heat Load Reduction vs Tilapia Concentration ............................. 22

Figure 16: Estimated, Calculated, & Averaged Thermal Resistance .............................. 23

vi

LIST OF SYMBOLS

Symbol

Description

Unit

Tw1

Upper bound water temperature

K

Tw2

Lower bound water temperature

K

T∞

Ambient air temperature

K

vw

Velocity of water flow

m/s

dt

Diameter of tilapia

m

rt

Radius of tilapia

m

lt

Length of tilapia

m

tw

Thickness of cement wall

m

Aw

Area of walls

m2

Asurf

Surface area of raceway

m2

Pa

Air pressure

Pa

Vw

Volume of System

m3

ρw

Density of water (32° C)

kg / m3

ρa

Density of air (10° C)

kg / m3

kw

Thermal conductivity of water (32° C)

W/m×K

ka

Thermal conductivity of air

W/m×K

kc

Thermal conductivity of cement

W/m×K

kt

Thermal conductivity of tilapia (Avg)

W/m×K

Cpw

Specific heat of water (32° C)

kJ / kg × K

Ca

Specific heat of air (10° C)

kJ / kg × K

Cpt

Specific heat of tilapia (Avg)

kJ / kg × K

Cpb

Specific heat of water and tilapia biomass weight averaged

kJ / kg × K

νw

Kinematic viscosity of water (32° C)

m2 / s

νa

Kinematic viscosity of air (10° C)

m2 / s

Viscosity of water (32° C)

Pa × s

Viscosity of air (10° C)

Pa × s

αCp

Ratio of tilapia specific heat to fresh water specific heat

-

αk

Ratio of tilapia conductance to fresh water conductance

-

vii

tw

Time to cool water only system

hrs

Re

Reynolds Number

-

Nu

Nusselt Number

-

Ra

Raliegh Number

-

Pr

Prandtl Number

-

Dh

Hydraulic Diameter of Raceway

m

qwall

Heat transfer through side walls of raceway

W

qfconv

Heat transfer from water surface due to free convection

W

qrad

Heat transfer from water surface due to radiation

W

qbase

Total heat transfer out of water only baseline system

W

Rbase

Thermal resistance of water only baseline system

W/K

Rest

Thermal resistance estimate including water and tilapia

W/K

Rtcond

Thermal resistance through a single tilapia body

W/K

Rtconv

Thermal resistance at the tilapia to water interface

W/K

Rfish

Thermal resistance of all tilapia in the raceway

W/K

Rcalc

Thermal resistance calculation including water and tilapia

W/K

Ravg

Thermal resistance average of Rest and Rcalc

W/K

viii

LIST OF KEYWORDS

Key Word

Description

Aquaculture

Fish farming

Ectotherm

Cold blooded animal

FCR

Feed conversion ratio

Oreochromis

niloticus

Recirculating

system

Nile tilapia species of fish

Aquaculture system which mechanical circulates and treats water

Biomass

Mass of living tissue in a system

Conduction

Mechanism of heat transfer through solids

Convection

Mechanism of heat transfer through liquids and gases

Radiation

Thermal resistance

Mechanism of heat transfer from a warm body to cooler surroundings

through electromagnetic waves

Material or system property which represents the resistance to heat

flow

ix

ACKNOWLEDGMENT

I would like to thank my friends Jared Feist and Christopher Stubbs for accompanying

me in the pursuit of my graduate degree in engineering as well as my family for their

continuous encouragement. I would also like to extend thanks to my wonderful girlfriend

for her unwavering support. A special debt of gratitude is also due to Dr. Ernesto

Gutierrez-Miravete for his understanding and guidance throughout the completion of this

project.

x

ABSTRACT

High capacity water heating and cooling mechanical systems are typically employed in

large scale recirculating aquaculture systems, specifically in regions where the product

species may be subject to sub-optimal growth rates at the extremes of ambient

temperature. To optimize the heating and cooling loads required to keep water

temperatures in a desired range, an analytical model of a recirculating raceway is

constructed and then used to account for the inclusion of the product species biomass.

The aquaculture system studied accounts for conduction, forced and free convection, as

well as radiative heat transfer mechanisms between the raceway and the ambient

surroundings as well as convective and conductive heat transfer through the product

species biomass. Several different concentrations of biomass are analyzed to provide

bounding assumptions as to the extent to which biomass may affect water heating and

cooling loads. An overall reduction in the heat capacity required to maintain system

temperature is calculated for each case studied. This reduction is a comparison of the

baseline heating load required to maintain the temperature of the control body of fresh

water against the heating load required to maintain the temperature of the system when

accounting for varying levels of biomass. The aquaculture system studied models

biomass based on the properties of oreochromis niloticus or Nile tilapia and varies

concentration of the fish from 10 to 30% of the total system mass. It is shown that heat

load reductions ranging from 2.5 to 4.7% percent respectively can be obtained for tilapia

when accounting for the biomass of the product species in the aquaculture system. A

general approximation is proposed which relates the specific heats and concentrations of

the product species farmed and the fresh water in a recirculating aquaculture facility to

the heating or cooling load reduction which may be obtained over a baseline water only

system.

xi

1. Introduction

1.1 State of the Aquaculture Industry

Aquaculture, or fish farming, has been practiced by mankind in its various forms for

thousands of years [1]. Similar to terrestrial farming, aquaculture implies some sort of

intervention in the rearing process of the farmed animal such as regular stocking,

breeding, feeding, and protection from predators, to enhance production. In the United

States, the emergence of aquaculture can be traced back to the mid-19th century;

however it was not until the 1960s that rapid expansion in both production and variety of

animal species farmed took hold [2]. In the ensuing years, per capita consumption of

protein derived from some type of aquatic life form has continued to increase in the

United States reflecting similar rates in the worldwide consumption of fish.

To meet this ever rising demand for aquatic sources of protein, producers have begun to

increasingly turn towards aquaculture. Traditional fishing in the world’s oceans and

other large bodies of water is becoming seen as a resource that has been tapped to its

maximum sustainable limit. This is due to overfishing, pollution, and habitat destruction

which have led to significant loss in fish populations and natural diversity [1]. On the

other hand, aquaculture provides a sustainable and controllable means of producing fish

to meet the demands of an ever growing population. The initial investment and

continued maintenance of aquaculture facilities present the main obstacles which must

first be overcome to take advantage of the benefits over traditional fishing practices.

As stated above, current aquaculture practices began in the 1960s in which significant

biological and engineering expertise began to enter the field to optimize production. At

its heart, aquaculture is inherently a more energy efficient enterprise than farming of

land based animals. First, fish are ectotherms (cold blooded) and do not expend energy

maintaining body heat. Secondly, fish are neutrally buoyant in their environment and

therefore do not have to expend energy to support their bodies. Lastly, fish exist in a

three dimensional environment which greatly increases final yield on a per acre basis

[2]. For these reasons, the feed conversion ratio (FCR) of fish, which is the ratio of an

1

animal’s efficiency in converting feed mass into a usable protein output, is much greater

than that of traditionally farmed animals like cattle and pigs, and is similar to that of

poultry [3]. This allows aquatic farmers to expend more energy in maintaining the

optimum environment for their product animal while still remaining competitive in the

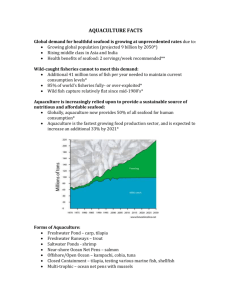

open market. Figure 1 below illustrates the recent growth of the aquaculture industry

with respect to Oreochromis niloticus, or Nile tilapia, which is one of the most

commonly farmed species of fish.

Figure 1: Aquaculture Production of Tilapia in Millions of Tons [4]

In the creation of the artificial habitats for the product animal, both biological sciences

and mechanical engineering practices come into play. Chemically, the water must be

free of toxins, pH balanced, and most importantly properly oxygenated to ensure the

survival of the product. Mechanically, the temperature and flow of the water must be

properly controlled to ensure an environment for optimal health and growth is

maintained. The mechanical aspect of controlling the water temperature for Nile tilapia

production will be further explored in the later sections of this report.

2

1.2 Types of Aquaculture

Modern aquaculture facilities for tilapia generally fall into one of four categories [5]. In

each category, the most important aspect of the water management system is to ensure

that clean and properly oxygenated water is provided to the product animal to ensure

survival. Of secondary, but also of very high importance is the control of water

temperature. Water must be controlled in the proper band of allowable temperatures to

ensure the following: survival of the product animal, rapid growth, and spawning. As

previously noted, all common commercially grown aquaculture products are ectotherms.

Therefore, these animals must rely on their environment to control body temperature,

with heat transfer taking place through gills and the body walls of the fish. The proper

water temperature encourages a high metabolic rate in the product animal which leads to

fast and efficient growth. Specific water temperatures are also required to allow animals

to spawn; however spawning is typically performed in smaller tanks and pens separate

from the main bodies of water used to grow-out fish to maturity. This provides

aquaculture farmers increased control over the spawning process.

The most common and least labor intensive, form of aquaculture is a pond water

production system. Nile tilapia are freshwater fish and therefore may be raised in inland

ponds fed by rainwater, streams and other larger lakes. These ponds may be natural or

man-made but must ultimately be large enough to induce a naturally occurring

ecosystem in which to sustain tilapia production. Harvest of fish is generally performed

by dragging large nets through the water.

Another common method of aquaculture production is cage culture, in which cages

made of netting are used to constrain the tilapia. Typically, these cages are placed in

much larger bodies of water than those that would be used in a pond water production

system and therefore the farmer has little control over the quality of the water in which

his fish grow. This can lead to sub-optimal growth conditions as well as exposure to any

toxins or pollutants that may be present in the ambient environment.

3

Flow-through raceway production systems are used in areas where an abundance of

fresh water flow is available, such as near large rivers of springs. These set ups usually

divert water from its source to allow for a continuous flow of new water through an open

trough which contains provisions to constrain the tilapia. Depending on the available rate

of water volume flowing through the raceway, the system may or may not need to be

mechanically supplemented to provide proper aeration for the density of tilapia

contained in the system.

The final category of aquaculture system, and the subject of this study, is a recirculating

system. These systems are used where water is not naturally available in significant

volume to use a flow through model or in regions where the ambient climate is not

suitable to permit year-round production of a particular species of fish. Recirculating

aquaculture systems may utilize earthen ponds, concrete tanks or some style of manmade raceway as the fish habitat. The most advanced re-circulating systems may be

located in large greenhouses or other climate controlled indoor facilities to aid in

mediation of ambient weather conditions and temperatures. Water treatment in

recirculating systems must include mechanical aeration to add dissolved oxygen,

mechanical filtration to remove large particulate, biological filters to enhance

nitrification and mechanical heating and cooling capacity to control water temperature

[5]. Figure 2 below shows raceway style tanks used in a recirculating aquaculture facility

while Figure 3 shows the high density of fish achievable in such a system.

Figure 2: Raceway Style Tank for Recirculating Aquaculture System [3]

4

Figure 3: Density of Fish in Raceway Style Tank [3]

In recirculating aquaculture systems, water heating and cooling capacity is often

generated through use of grid coil heat exchangers immersed directly in the tanks or

raceways which are used to grow-out fish to full maturity. A separate loop of

temperature maintained water is passed through these heat exchangers and is used to

maintain the overall temperature of the fish habitat. The quantity and size of the heat

exchangers present in the raceway or tank controls the maximum heating or cooling

capacity that can be delivered to the aquaculture system. Figure 4 shows a standard grid

coil heat exchanger.

Figure 4: Grid Coil Heat Exchanger [6]

5

Standard engineering practices for sizing the maximum heating or cooling loads required

to maintain optimal temperature in a recirculating aquaculture system involve

identifying the worst case ambient temperatures to which the system will be exposed,

identifying the optimal temperature band for fish growth, and calculating the expected

heat transfer into or out of the system based on the thermal resistance of the physical

system, the ambient temperature extremes, and the optimal temperatures. These

calculations are generally performed using the thermophysical properties of water only

to quantify heat loss or gain of the system through the mechanisms of conduction,

convection, and radiation.

The use of water properties alone in the sizing of heat loads for an aquaculture system

introduces an inherent conservatism in the capacity of the mechanical system designed

for maintaining water temperature. Identification of, and in appropriate cases elimination

of this conservatism may allow future recirculating aquaculture facilities to be optimally

and more cost effectively designed for the actual heat loads required by the system.

6

2. Theory and Methodology

This project explores the postulate that biomass should be accounted for when

performing required heat load calculations for recirculating aquaculture water heating

and cooling systems. The basis for this postulate is the addition of conductive and

convective heat transfer mechanisms that must occur within and at the boundary of the

biomass inside of the body of water. Table 1 below shows the thermal properties

(including conductivity and specific heat) of several species that are commonly grown in

aquaculture farms:

Table 1: Thermal Properties of Seafood [7]

Review of the information included in Table 1 shows that the conductivity of all

common species of animals grown in aquaculture farms is less than that of fresh water

(0.616 W/m·K [8]). The result of this natural phenomenon is that the heat transfer out of

a body of water containing a particular concentration of fish should face a higher

resistance than heat transfer out of a system containing only fresh water, even when

accounting for mainly convective heat transfer through the body of water. Therefore, the

potential for optimization of heating or cooling loads required to maintain a specific

water temperature exists and is likely dependent upon the percentage of biomass in the

system.

7

2.1 Theoretical System

To test the postulate proposed in this report, a control system is proposed with

parameters which attempt to adequately represent current commercial recirculating

aquaculture practices. To accomplish this end, a raceway style recirculating aquaculture

system was used to simulate a body of fresh water used to grow the Nile tilapia species

of fish. The raceway model used is a rectangular pool with cement walls in which the

length is many times greater than the width and the depth of water is kept to a minimum.

This design is optimal for indoor recirculating aquaculture facilities as the geometry of

the pool provides a natural river-like flow pattern from one end of the raceway to the

other to reduce eddy currents and aid in ensuring continued water replacement and

particulate removal. The total volume of water that fills the raceway must be cycled

through filter, aeration, and across temperature control systems at least once per day to

ensure sufficient water quality and temperature is maintained to allow for optimal

growth conditions of the aquaculture product. Figure 5 below shows the overall

geometry of the raceway used in this study:

Figure 5: Raceway Dimensions

The system represents a large section of a raceway pool; however it does not include the

ends of the raceway. This is done to simplify analysis by removing the need to consider

end effects of water discharge and return. These effects complicate analysis but do not

8

provide significant added value to the investigation at hand as the net result on the

heating or cooling loads would be the same for either a large body of water or one that

contains a concentration of biomass.

As stated earlier, this system is used to simulate the growth of Nile tilapia. The optimal

temperature for growth of tilapia is between 28 and 32°C, with growth declining greatly

as temperature decreases. Temperatures 10°C and below are considered lethal [5]. The

theoretical system therefore exists in an ambient environment of 283.15 K (10°C) with

initial water temperature of 305.15 K (32°C). Replacement of the entire volume of water

occurs once per day resulting in a steady current in the water from end to the other.

2.2 Analytical Method

This study uses the model proposed above to analyze the heat transfer phenomena in the

recirculating raceway. Figure 6 below shows the heat transfer mechanisms of

conduction, forced convection, free convection and radiation that are considered

between the raceway system and the ambient environment:

Figure 6: Heat Transfer Between Raceway and Surroundings

Forced convection occurs at the water to wall interface and heat transfer continues via

conduction through the wall. Free convective and radiative heat transfer occurs at the

water surface and transfers heat to the ambient surroundings. The mechanisms shown

9

pictorially in Figure 6 are equivalent to the standard engineering practices for sizing the

maximum heating load of a system. Evaluating heat loads in this manner treats the

volume of water as a single lumped mass with all heat transfer occurring only at the

boundary of the system. Figure 7 below shows the heat transfer diagram of a

recirculating raceway aquaculture system without considering biomass. As can be seen,

three parallel paths for heat transfer out of the system exist and the body of water is a

single lumped mass with temperature Tw.

Figure 7: Heat Transfer Diagram – Without Biomass

The treatment of the volume of water as a single lumped mass would be accurate for a

system consisting entirely of water. However, the introduction of fish into the system

adds a second ‘layer’ of heat transfer which must occur for energy initially in the

biomass to exit the system. Considering the conduction which must occur through the

body of the fish and the convection that must occur at the surface of the fish to water

interface therefore presents additional thermal resistance to the flow of thermal energy

out of the baseline system. Figure 8 below shows the heat transfer diagram which will be

used to simulate the effects of biomass in an aquaculture system.

10

Figure 8: Heat Transfer Diagram – With Biomass

This diagram represents the path of energy flow from the interior of a fish into the

ambient surroundings. Heat flow is considered to occur in parallel for the individual

representative fish masses. The temperature gradient through the body of water is

ignored for both systems and water temperature is treated as a bulk property.

2.2.1

Definition of System Parameters

The following thermophysical properties of water, air, and Nile tilapia are used in all

thermal resistance estimates and calculations performed in this study:

Table 2: Thermophysical Properties [7] & [8]

Variable

ρw

ρw

ρf

kw

ka

kc

kt

Cpw

Cpt

w

a

Description

Density of water (32° C)

Density of air (10° C)

Density of water (32° C)

Thermal conductivity of water (32° C)

Thermal conductivity of air

Thermal conductivity of cement

Thermal conductivity of tilapia (Avg)

Specific heat of water (32° C)

Specific heat of tilapia (Avg)

Viscosity of water (32° C)

Viscosity of air (10° C)

11

Value

996.025

1.1614

996.025

0.616

0.496

0.720

0.4961

4.181

3.513

8264 x 10-7

185 x 10-7

Unit

kg / m3

kg / m3

kg / m3

W/mK

W/mK

W/mK

W/mK

kJ / kg K

kJ / kg K

Pa s

Pa s

Table 3 below details the properties of the recirculating raceway aquaculture system

which are assumed for this study:

Table 3: Raceway Aquaculture System Properties

Variable

Tw1

Tw2

T∞

vw

rt

tw

Aw

Asurf

Vw

2.2.2

Description

Upper bound water temperature

Lower bound water temperature

Ambient air temperature

Velocity of water flow

Radius of tilapia

Thickness of cement wall

Area of walls

Surface area of raceway

Volume of System

Value

305.15

301.15

283.15

0.0126

0.08

.010

200

1000

1000

Unit

K

K

K

m/s

m

m

m2

m2

m3

General Assumptions

The proposed model uses the following major assumptions; additional assumptions are

made for specific calculations and are explained in the applicable section:

1. The bulk temperature of the body of water and biomass is considered constant

and does not vary along the length of the raceway. This is due to the use of

immersed grid coil heat exchangers throughout the length of the raceway which

provide a steady input of thermal energy into the system.

2. Temperature gradients in the water are negligible. Water temperature is a bulk

property of the system. This is due to the system being modeled as a steady state.

3. Temperature gradients in the biomass are negligible. Biomass temperature is a

bulk property of the system. This is due to the system being modeled as a steady

state.

2.2.3

Heat Transfer Through Side Walls

To quantify the heat transfer through the cement side walls of the raceway aquaculture

system, conductive and forced convective heat transfer mechanisms are considered. Heat

transfer due to conduction is simply based off of linear heat conductance theory shown

in Equation 1. Thermal resistance due to conduction is calculated by Equation 2.

𝒒𝒄𝒐𝒏𝒅 = 𝒌𝒄 × 𝑨𝒘

12

𝑻∞ −𝑻𝒘

𝒕𝒘

[1]

𝑹=𝒌

𝒕𝒘

𝒄 ∙𝑨𝒘

[2]

Forced convection at the water to wall boundary is calculated based off a Nusselt

number approximation for turbulent flow over a flat surface. The flow was determined to

be turbulent based on a calculated of a Reynolds number of 50620. This calculation

accounts for the raceway style flow by use of a hydraulic diameter calculated by

Equation 3.

𝑫𝑯 =

𝟒𝒂𝒃

𝟐𝒂+𝒃

[3]

The Nusselt number approximation used in this study is provided in Equation 4.

𝑵𝒖 = 𝟎. 𝟎𝟐𝟗𝟔 ∙ 𝑹𝒆𝟎.𝟖 ∙ 𝑷𝒓𝟎.𝟑𝟑

[4]

A coefficient of heat transfer is determined based on the calculated Nusselt number and

the thermophysical properties of water. Thermal resistance due to convection is

determined though use of Equation 5.

𝑹=𝒉

𝟏

𝒘 ∙𝑨𝒘

[5]

The thermal resistance of both conduction and convection are combined to find the total

heat transfer out of the system through the side wall, qwall, at the ambient temperatures

given in Table 3. All detailed calculations can be found in Appendix A.

𝑞𝑤𝑎𝑙𝑙 = 28,000 𝑊

2.2.4

Free Convective Heat Transfer from Surface

Heat transfer from the surface of the water in the raceway aquaculture system into the

ambient air is calculated based on the Nusselt number approximation shown in Equation

6 for free convection from a horizontal surface.

𝑵𝒖 = 𝟎. 𝟏𝟓 ∙ 𝑹𝒂𝟎.𝟑𝟑

[6]

The result of this approximation is used to determine the coefficient of heat transfer for

free convection. Equation 5 is again used to determine the resistance to free convective

heat transfer from the surface of the water to the air. The total heat transfer out of the

13

system due to free convection, qfconv, is then calculated. All detailed calculations can be

found in Appendix A.

𝑞𝑓𝑐𝑜𝑛𝑣 = 111,000 𝑊

2.2.5

Radiation Heat Transfer from Surface

A conservative value of radiation heat transfer from the surface of the water in the

raceway aquaculture system to the surrounding environment is calculated by assuming a

high emissivity of water and no irradiative energy reflected back into the water. The total

heat transfer out of the system due to radiation is qrad. All detailed calculations can be

found in Appendix A.

𝑞𝑟𝑎𝑑 = 125,000 𝑊

2.3 Baseline Heat Loads

The baseline system consisting of fresh water only is subject to all three heat transfer

mechanisms discussed in the previous sections. Combining all methods results in the

total sustained heat loss out of the raceway aquaculture system, qbase, and provides the

baseline required heat load needed to maintain constant temperature in a water only

system.

𝑞𝑏𝑎𝑠𝑒 = 265,000 𝑊

This value represents the result of following traditional aquaculture engineering

practices for sizing the maximum required heating load to maintain temperature in a

recirculating aquaculture system. To provide a basis for later calculations, a total system

resistance to heat transfer, thermal resistance Rbase, is calculated using Equation 7.

𝑹𝒃𝒂𝒔𝒆 =

(𝑻𝒘𝟏 −𝑻𝒊𝒏𝒇 )

[7]

𝒒𝒃𝒂𝒔𝒆

𝑅𝑏𝑎𝑠𝑒 = 0.00008302

𝐾

𝑊

Figure 9 below represents the simplified heat transfer diagram for the water only

baseline system and is a combination of all three parallel heat transfer paths in Figure 7.

14

Figure 9: Simplified Heat Transfer Diagram – Baseline System

2.4 Introduction of Biomass

When biomass is introduced into the fixed volume aquaculture system, water volume is

removed and replaced with fish biomass which is a solid and also consists of different

thermophysical properties than the water. The result of the added biomass is that

additional heat transfer mechanisms between the body of water and the fish biomass are

introduced which are not present in the baseline system. A simplified heat transfer

diagram for the flow of heat through the added biomass and out of the raceway

aquaculture system is shown below in Figure 10. This simplified diagram combines all

parallel paths of heat transfer from individual fish into a single thermal resistance, Rfish.

Figure 10: Simplified Heat Transfer Diagram – Biomass System

To account for the thermal resistance of the fish biomass an appropriate model of the

individual fish introduced to the system is constructed and the concentration of the fish

mass is determined. The model used in this study for tilapia is representative of a

medium sized adult male fish which can average 1 kg (2.2 lbs.) in weight. The tilapia is

modeled as a cylinder with diameter of 0.16 m and length of 0.20 m [10]. The

thermophysical properties of the cylinder are those defined in Table 2. The mass density

of Nile tilapia is assumed to be identical to that of water due to neutral buoyancy.

15

Figure 11: Tilapia Model

In a raceway style aquaculture system, common concentrations of tilapia range from

160-185 kg/m3 [11]. Introducing tilapia as modeled above to the raceway system at this

prescribed concentration results in approximately 20% of the system as biomass. To

provide additional insight into the effects of biomass on the thermal transfer within the

aquaculture system, five separate cases both above and below the average concentration

are considered. The concentrations studied are defined in Table 4 below:

Table 4: Concentration of Tilapia in Raceway

Case 1 Case 2 Case 3 Case 4 Case 5

10%

15%

20%

25%

30%

2.4.1

Modeling Biomass Resistance

Two methods are used to determine the increase in thermal resistance in the raceway

system due to the inclusion of biomass. First, a general estimate is made based on the

thermophysical properties of the fresh water, fish biomass and the overall time to cool

the system. Second, a more detailed investigation of the increase to thermal resistance of

the system due to biomass is pursued through calculation of the convective and

conductive heat transfer mechanisms occurring at the surface of and internal to the fish.

2.4.2

Resistance Estimate

To estimate the increase in the thermal resistance of the system due to inclusion of fish

biomass the lumped heat capacitance formula for cooling of a heated body is used. This

formula is shown in Equation 8 below:

16

𝑻𝒘𝟏 −𝑻𝒊𝒏𝒇

𝒕 = 𝝆𝒘 ∙ 𝑽𝒘 ∙ 𝑪𝒑 ∙ 𝑹𝒃𝒂𝒔𝒆 ∙ 𝒍𝒏 (𝑻

𝒘𝟐 −𝑻𝒊𝒏𝒇

)

[8]

This equation is first used to find the time required to cool the baseline water only

system from an initial temperature of 305.15 K (32°C) to 301.15 K (28°C) with an

ambient outside temperature of 283.15 K (10°C) and the overall thermal resistance of the

system of Rbase. The calculated time to cool, tw, represents the duration of time that must

pass in the ambient conditions for the baseline water only system to cool 4 K.

𝑡𝑤 = 19.271 ℎ𝑟𝑠

Using this calculated time and making the assumption that the time required to cool a

system with biomass is very similar to that of a water only system, a rough estimate of

the increased thermal resistance of the system when including biomass is determined. A

weight averaged specific heat, Cpb, accounting for the concentration of tilapia in the

system is calculated by use of Equation 9 and is substituted for the specific heat of water.

𝑪𝒑𝒃 = (𝑷𝒆𝒓𝒄𝒆𝒏𝒕 𝑾𝒂𝒕𝒆𝒓 ∙ 𝑪𝒑𝒘 ) + (𝑷𝒆𝒓𝒄𝒆𝒏𝒕 𝑩𝒊𝒐𝒎𝒂𝒔𝒔 ∙ 𝑪𝒑𝒕 ) [9]

Equation 8 is then rearranged to solve for the resistance estimate, Rest, of the new system

as shown in Equation 10.

𝒕𝒘

𝑹𝒆𝒔𝒕 =

𝑻𝟏 −𝑻𝒊𝒏𝒇

)

𝑻𝟐 −𝑻𝒊𝒏𝒇

[10]

𝝆∙𝑽∙𝑪𝒑𝒃 ∙𝒍𝒏(

It is noted that this estimate does not directly calculate thermal resistance due to

convective heat transfer at the surface of the fish or conductive heat transfer through the

volume of fish mass that has been introduced into the system; however it does allow for

a rough approximation of the effect of these heat transfer mechanisms. The estimate

assumes that the decrease in the specific heat of the system due to the addition of the fish

biomass (Cpb) is directly offset by the increased thermal resistance due to convective and

conductive heat transfer through the biomass. This basis of this estimate is considered

valid by a comparison of the ratios of the specific heat and thermal conductivity for Nile

tilapia and water as shown below:

𝛼𝐶𝑝 =

𝐶𝑝𝑡

= 0.84

𝐶𝑝𝑤

17

𝛼𝑘 =

𝑘𝑡

= 0.80

𝑘𝑤

The ratio of specific heats, αCp, indicates the effect on the energy required to change the

temperature of the system with biomass. Since the ratio is less than 1, the time to cool

the new system should decrease given a constant heat loss qbase as less energy loss is

required to cool the system. The ratio of thermal conductance, αk, indicates the effect on

the thermal resistance on the system with biomass. Since this ratio is less than 1, the

resistance to change in temperature in the new system should increase as it indicates

energy conducts more easily through water than tilapia biomass. Since the ratio of

specific heats is closer to 1 than the ratio of conductance (e.g. the tilapia thermophysical

property is more similar to that of water), the effect of biomass on the thermal resistance

of the system should be greater than the effect of biomass on the energy required to

change the temperature of the system. This initial estimate is used to provide a reference

point from which to begin a more detailed analysis of the theoretical system.

2.4.3

Resistance Calculation

To introduce biomass into the recirculating aquaculture system, individual Nile tilapia

are considered which weigh 1 kg and are modeled as cylinders with radius, rt = 0.08 m

and length lt = 0.2 m. For this calculation, water temperature is again treated as a bulk

property due to steady state conditions. Making this assumption allows the dispersal

pattern of the biomass in the system to be random as no temperature profile is considered

throughout the water mass. The assumption does not impact calculations on the

increased thermal resistance of an aquaculture system with biomass as the temperature

profile through the water mass is also ignored in baseline calculations. Figure 12 below

shows a cross-sectional view of the system with the introduction of biomass:

18

Figure 12: Introduction of Nile tilapia biomass

A second important assumption in the modeling of biomass in the aquaculture system is

the neglecting of end effects of heat transfer through the tilapia. All heat transfer

calculations are performed as a 2D cross-section of the system and then applied to the

entire length of the raceway. To this end, tilapia mass is modeled into the system in 100

m long cylinders of radius rt with each cylinder representing 500 individual fish. Table 5

below shows the total number of fish approximated for each case studied and the number

of representative cylinder present in a given cross-section of the raceway:

Table 5: Number of Tilapia in the Aquaculture System

Case 1

Individual Fish

Representative Cylinders (Nt)

2.4.4

Case 2

Case 3

Case 4

99,500 149,000

199,000

248,500 298,000

199

298

398

497

Case 5

598

Resistance Calculation - Convection

To calculate the increase in thermal resistance due to convective heat transfer from the

fish biomass into the surrounding water, the number of fish in the system is determined

based on the biomass concentration in each specific case. A convective heat transfer

coefficient is then calculated based on the system characteristics and the total surface

area of the fish modeled for each different scenario. Thermal resistance due to

convection is determined by Equation 5. All detailed calculations can be found in

Appendix A.

19

2.4.5

Resistance Calculation - Conduction

The thermal resistance due to conductive heat transfer through the fish biomass is

calculated by use of the fish radius, rt, thermal conductivity, kt an assumed inner

diameter of the fish rt1.

𝑹𝒕𝒄𝒐𝒏𝒅 =

𝒓

𝒍𝒏( 𝒕 )

𝒓𝒕𝟏

[11]

𝟐∙𝝅∙𝟏𝟎𝟎𝒎∙𝒌𝒕

The constant rt1 is chosen to allow for the majority of the fish mass to be accounted for

in the thermal resistance due to conduction through the fish body. Similar to the body of

water, the temperature distribution in the fish is ignored and considered to be a bulk

property due to steady state conditions. All detailed calculations can be found in

Appendix A.

2.4.6

Resistance Calculation - Consolidation

As shown in Figure 8, the thermal resistance of the system due to fish biomass is a

network of parallel conductive and convective heat transfer paths occurring through the

individual fish, into the body of water and finally out into the ambient environment. The

following equation is used to calculate the thermal resistance of all parallel paths of heat

transfer that originate within the tilapia biomass:

𝑹𝒇𝒊𝒔𝒉 =

𝟏

(

𝟏

𝑹𝒕𝒄𝒐𝒏𝒗 +𝑹𝒕𝒄𝒐𝒏𝒅

)∙𝑵𝒕

+ 𝑹𝒃𝒂𝒔𝒆

[12]

The variable Nt is the number of tilapia found in a cross section of the system at any

given point along the raceway. A final calculation is performed as part of the resistance

calculation to combine the parallel paths of heat transfer that occur out of the water only

and the heat transfer which originates in the biomass and also passes through the water.

Figure 13 below shows the simplified heat transfer diagram:

20

Figure 13: Simplified Heat Transfer Diagram – Water and Tilapia

These paths of heat transfer are averaged based on the weight concentration of fish in the

system to accurately represent the impact of each thermal resistance path on the system

as a whole. Equation 13 provides the formula used to average the system resistance

based on weight concentrations.

𝑹𝒄𝒂𝒍𝒄 =

𝟏

(

𝟏

𝑹𝒃𝒂𝒔𝒆

2.4.7

∙𝑷𝒆𝒓𝒄𝒆𝒏𝒕 𝑾𝒂𝒕𝒆𝒓)+(

𝟏

𝑹𝒇𝒊𝒔𝒉

[13]

∙𝑷𝒆𝒓𝒄𝒆𝒏𝒕 𝑩𝒊𝒐𝒎𝒂𝒔𝒔)

Final Resistance

To reduce the impact of assumptions made in both the thermal resistance estimate and

the thermal resistance calculation, the results of each method are averaged for each case

study. This average thermal resistance is used to compute the new total heat transfer out

of the system for the various levels of biomass concentration. All detailed calculations

can be found in Appendix A.

21

3. Results and Discussion

The thermal resistances determined in this report result in a reduction to heat loads

required to maintain system temperature versus the baseline water only calculation. As

expected, the reduction in overall heat loads positively correlates to the percentage of

biomass in the system. Figure 14 and Figure 15 below summarize the effects of the

thermal resistances calculated as part of this study on required heat loads.

Required Heat Load to Maintain

Temperature

Heat Load (W)

270000

265000

260000

255000

250000

245000

0%

10%

15%

20%

25%

30%

Tilapia Concentration

Figure 14: Required Heat Load vs Tilapia Concentration

Heat Load Reduction

Required Heat Load Reduction

5.0%

4.5%

4.0%

3.5%

3.0%

2.5%

2.0%

1.5%

1.0%

0.5%

0.0%

0%

10%

15%

20%

25%

Tilapia Concentration

Figure 15: Required Heat Load Reduction vs Tilapia Concentration

22

30%

The basis for the heat load reduction is the increased thermal resistance of the system as

a whole due to the inclusion of biomass in heat transfer calculations. The estimated,

calculated, and average thermal resistances calculated in this study are shown in Figure

16.

Estimated, Calculated & Average Thermal

Resistance

0.00009200

Thermal Resistance (K/W)

0.00009000

0.00008800

0.00008600

Calculated Resistance

0.00008400

Estimated Resistance

Averaged Resistance

0.00008200

0.00008000

1%

4%

7%

10%

13%

16%

19%

22%

25%

28%

31%

34%

37%

40%

43%

46%

49%

0.00007800

Tilapia Concentration

Figure 16: Estimated, Calculated, & Averaged Thermal Resistance

The above figure shows reasonable agreement between the estimated and calculated

thermal resistances. As methods for determining both the estimated and calculated

thermal resistance of biomass in the system did not overlap, this indicates increased

confidence in the calculation methods described in the preceding sections.

It is also clear in Figure 16 that the relationship of the tilapia concentration to thermal

resistance differs for the estimated and calculated methods. The estimated thermal

resistance shows a clear positive linear correlation between increase in tilapia

concentration and increase in thermal resistance. This type of correlation for the

estimated thermal resistance is expected due to the assumptions made and method of

linear change of specific heat used in the estimation. However, the calculated thermal

23

resistance of the system shows a clearly different relationship. The initial increase in

tilapia concentration (from 1% to 15%) results in an increase in thermal resistance at a

rate much higher than the estimated method. However, the calculated thermal resistance

quickly levels off after biomass concentration levels hit 15% with only gradual increase

in thermal resistance for increasing tilapia concentration. This effect is due to the

conductive and convective heat transfer considered for each individual tilapia occurring

in parallel. As a basic principle of thermal resistance circuits, the more pathways that

exist in parallel in a given system (the number of tilapia increase), the greater the

decrease in overall thermal resistance. This results in a leveling off of the calculated

thermal resistance. Review of calculations does show that the thermal resistance

calculated for all tilapia actually does decrease as more fish are added into the system.

This decrease is offset due to the fact that resistance through the tilapia is still always

greater than the baseline resistance due to water only, and therefore the total calculated

resistance of the system continues to increase with higher levels of biomass

concentration.

It is also noted that the calculated method results in a greater thermal resistance of the

system for tilapia concentrations less than 30% of total system mass, while the estimated

method begins to result in a greater thermal resistance of the system for concentrations

above 30%. A sensitivity analysis on the effect of fish size on thermal resistance reveals

that the intersection point for the two methods varies. When a fish model of half of the

mass (0.5 kg) is used at the same overall biomass concentration levels, the intersection

point drops to approximately 15% before the estimated method for resistance calculation

becomes greater. This is important as it shows a dependence of increased thermal

resistance on not only the concentration of biomass in a system but on the physical

characteristics of the biomass itself.

24

4. Conclusion

This study constructs an analytical model of a recirculating aquaculture system and

determines the effect of varying levels of biomass on the heat transfer out of the system.

The model is a raceway aquaculture system used to grow Nile tilapia with an ambient

temperature differential of 22°C between the system and ambient environment. Five

different levels of biomass were modeled into the system and their effect on the overall

thermal resistance to heat flow out of the aquaculture system was determined. The

thermal resistance due to biomass was first estimated and then calculated in an attempt

to control the influence of individual assumptions made in each method.

It was determined that biomass does have a measurable, albeit low percentage, impact on

overall heat loads required to maintain temperature in a given aquaculture system.

Thermal resistance increases as more fish are added to the raceway, however the level of

increase is contingent not only upon the total concentration of biomass in the system but

also upon the size of the individual fish the system. For the specific system studied, 1 kg

Nile tilapia ranging from 10 to 30% of total system mass, heat load reductions ranging

from 2.5 to 4.7% percent can be obtained when accounting for the biomass of the

product species in the aquaculture system.

To convert the results of this study for practical applications, the following

approximation is proposed for reducing the size of heat loads required to maintain

temperature in a recirculating aquaculture system of larger fish (mass 1 kg or greater):

𝑹𝒆𝒅𝒖𝒄𝒕𝒊𝒐𝒏 𝒊𝒏 𝑯𝒆𝒂𝒕𝒊𝒏𝒈 𝒐𝒓 𝑪𝒐𝒐𝒍𝒊𝒏𝒈 𝑪𝒂𝒑𝒂𝒄𝒊𝒕𝒚 = 𝟏 −

(𝑷𝒃 × 𝑪𝒑𝒃 ) + (𝑷𝒘 × 𝑪𝒑𝒘 )

𝑪𝒑𝒘

For this approximation, Pb is the percentage of biomass in the system and Cpb is the

specific heat of the biomass. Cpw and Pw are the specific heat and percentage of water

and the system respectively. This approximation is considered valid for fish of 1 kg in

weight and for biomass concentration levels up to 30%. Further study may be pursued to

provide bounding constraints for validity for this approximation for other sizes of fish.

25

5. References

[1]

Kathryn White, Brendan O’Neil, and Zdravka Tzankova, At a Crossroads: Will

Aquaculture Fulfill the Promise of the Blue Revolution? Copyright © 2004

[2]

LaDon Swann, A Basic Overview of Aquaculture History, Water Quality, Types

of Aquaculture, Production Methods, August 1992

[3]

Raise Fish Around the Globe, startsomegood.com/fisharoundtheglobe, Site

visited November 9, 2014

[4]

Food and Agriculture Organization of the United Nations, faostat.fao.org,

Copyright © 2013

[5]

Claude E. Boyd, Farm-Level Issues in Aquaculture Certification: Tilapia

[6]

Empire State Plating Products, filterpumpeast.com/Process_Technology_Page,

Site visited November 9, 2014

[7]

[8]

Measurement of Thermal Properties of Seafood; Radharkishnan, Sudhahrini;

Thesis Virginia Polytechnic Institute and State University June 26, 1997

Transport Phenomena in Multiphase Systems; A. Faghri and Y. Zhang;

Copyright © 2006; Elsevier Inc. – Appendix B, Page 980, Table B.48

[9]

Fundamentals of Heat and Mass Transfer; F. Incropera, D. Dewitt, T. Bergman,

A. Lavine; Copyright © 2007; John Wiley & Sons Inc.

[10]

Tilapia: Life History and Biology, thefishsite.com/articles/58/tilapia-life-historyand-biology,Copyright © 2000, site visited November 16, 2014

[11]

Cultured Aquatic Species Information Programme, Oreochromis niloticus

(Linnaeus, 1758), Food and Agriculture Organization of the United Nations,

fao.org/fishery/culturedspecies/Oreochromis_niloticus/en, Copyright © 2014,

site visited November 16, 2014

26

Appendix A - Calculations

27