Effects of Biomass in Recirculating Aquaculture Water Heating and

Cooling Systems

by

Devin Scot Murray

Engineering Project Submitted to the Graduate

Faculty of Rensselaer Polytechnic Institute

in Partial Fulfillment of the

Requirements for the degree of

MASTER OF ENGINEERING

Major Subject: Mechanical Engineering

Approved:

_________________________________________

Prof. Ernesto Gutierrez-Miravete, Thesis Adviser

Rensselaer Polytechnic Institute

Hartford, CT

December, 2014

i

© Copyright 2014

by

Devin Scot Murray

All Rights Reserved

ii

CONTENTS

Effects of Biomass in Recirculating Aquaculture Water Heating and Cooling Systems ... i

LIST OF TABLES ............................................................................................................ iv

LIST OF FIGURES ........................................................................................................... v

ACKNOWLEDGMENT .................................................................................................. vi

ABSTRACT .................................................................................................................... vii

1. Introduction.................................................................................................................. 1

1.1

State of the Aquaculture Industry ...................................................................... 1

1.2

Types of Aquaculture ......................................................................................... 2

2. Theory .......................................................................................................................... 5

2.1

Theoretical System ............................................................................................. 5

2.2

Methods of Heat Transfer .................................Error! Bookmark not defined.

3. Method ......................................................................................................................... 7

3.1

3.2

Analytical Analysis ............................................................................................ 7

3.1.1

Definition of System Parameters ........................................................... 9

3.1.2

Conductive Heat Transfer .................................................................... 10

3.1.3

Convective Heat Transfer .................................................................... 10

3.1.4

Radiation Heat Transfer ....................................................................... 10

Computational Analysis ................................................................................... 10

4. Results........................................................................................................................ 11

5. Discussion and Conclusion ........................................................................................ 12

6. References.................................................................................................................. 13

iii

LIST OF TABLES

Table 1: Thermal Properties of Seafood [2] ...................................................................... 5

Table 2: System Parameters............................................................................................... 9

Table 3: Concentration of Tilapia in Raceway ................................................................ 10

iv

LIST OF FIGURES

Figure 1: Aquaculture Production of Tilapia in Millions of Tons [3] ............................... 2

Figure 2: Raceway Style Tank for Recirculating Aquaculture System ............................. 4

Figure 3: Density of Fish in Raceway Style Tank ............................................................. 4

Figure 4: Raceway Dimensions ......................................................................................... 6

Figure 5: Heat Transfer Mechanisms ................................................................................ 7

v

ACKNOWLEDGMENT

I would like to thank my friends Jared Feist and Christopher Stubbs for accompanying

me on the pursuit of my graduate degree in engineering as well as my family for their

continuous encouragement. I would like to extend thanks to my wonderful girlfriend for

her unwavering support. A special debt of gratitude is also due to Dr. Ernesto GutierrezMiravete for his understanding and guidance throughout the completion of this project.

vi

ABSTRACT

High capacity water heating and cooling mechanisms are typically employed in large

scale recirculating aquaculture systems, specifically in regions where the product species

may be subject to sub-optimal growth rates at the extremes of ambient temperature. To

optimize the heating and cooling loads required to keep water temperatures in a desired

range, an analytical model of a recirculating raceway is constructed and analyzed to

account for the inclusion of the product species biomass. The aquaculture system studied

accounts for conduction, forced and free convection, as well as radiative heat transfer

mechanisms between the raceway and the ambient surroundings. Several different

concentrations of biomass are analyzed to provide bounding assumptions to the extent to

which biomass may affect water heating and cooling loads. An overall efficiency is

calculated for each system studied which is based on the heating load required to

maintain

the

temperature

of

the

vii

control

body

of

fresh

water.

1. Introduction

1.1 State of the Aquaculture Industry

Aquaculture, or fish farming, has been practiced by mankind in its various forms for

thousands of years [1]. Similar to terrestrial farming, aquaculture implies some sort of

intervention in the rearing process of the farmed animal such as regular stocking,

breeding, feeding, and protection from predators, to enhance production. In the United

States, the emergence of aquaculture can be traced back to the mid-19th century;

however it was not until the 1960s that rapid expansion in both production and variety of

species farmed took hold [2]. In the ensuing years, per capita consumption of protein

derived from some type of aquatic life form has continued to increase reflecting similar

rates in the worldwide consumption of fish.

To meet this ever increasing demand for aquatic sources of food, producers have begun

to increasingly turn towards aquaculture. Traditional fishing in the world’s oceans and

other large bodies of water is increasingly seen as a resource that has been tapped to its

maximum sustainable limit. This is due to overfishing, pollution and habitat destruction

which have led to significant loss in fish populations and natural diversity [1].

Aquaculture provides a sustainable and controllable means of producing fish to meet the

demands of an ever growing population whose diet is increasingly consisting of more

and more aquatic proteins.

As stated above, current aquaculture practices began in the 1960s in which significant

biological and engineering expertise began to enter the field to optimize production. At

its heart, aquaculture is inherently more energy effective than farming of land based

animals. First, fish are ectotherms (cold blooded) and do not expend energy maintaining

body heat. Secondly, fish are neutrally buoyant in their environment and therefore do not

have to expend energy to support their bodies. Lastly, fish exist in a three dimensional

environment which greatly increases final yield on a per acre basis [2]. For these

reasons, the feed conversion ratio (FCR) of fish, which is the ratio of an animal’s

efficiency in converting feed mass into a usable output, is much greater than that of

1

traditionally farmed animals like cattle and pigs, and similar to that of poultry. This

allows aquatic farmers to expend more energy in maintaining the optimum environment

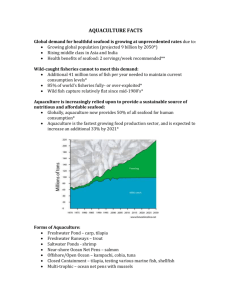

for their stock animal and remain competitive in the open market. Figure 1 below

illustrates the growth of the aquaculture industry with respect to tilapia, which is one of

the most commonly farmed species of fish.

Figure 1: Aquaculture Production of Tilapia in Millions of Tons [3]

In the creation of the artificial habitats for the product animal, both biological sciences

and mechanical engineering practices come into play. Chemically the water must be free

of toxins, pH balanced, and most importantly properly oxygenated to ensure the survival

of the product. Mechanically the temperature and flow of the water must be properly

controlled. The mechanical aspect of controlling the water temperature for tilapia

production will be further explored in later sections of this report.

1.2 Types of Aquaculture

Modern aquaculture facilities for tilapia generally fall into one of four categories [4]. In

each category, the most important aspect of the water management system is to ensure

clean properly oxygenated water is provided to the product animal to ensure survival. Of

2

secondary, but very high importance is the control of water temperature. Water must be

controlled in the proper band of allowable temperatures to ensure the following: survival

of the product animal, rapid growth, and spawning. As previously noted, all common

commercially grown aquaculture products are ectotherms. Therefore, these animals must

rely on their environment to control body temperature, with heat transfer taking place

through gills and the body walls. The proper temperature encourages a high metabolic

rate in the product animal leading to fast and efficient growth. Specific water

temperatures are also required to allow animals to spawn.

The most common and least labor intensive is a pond water production system. Tilapias

are freshwater fish and therfore may be raised in inland ponds fed by rainwater, streams

and other larger lakes. These ponds may be naturally occurring or man-made but must

ultimately be large enough to induce a naturally occurring ecosystem in which to sustain

tilapia production.

Another common method of aquaculture production is cage culture, in which cages

made of netting are used to constrain the tilapia. Typically these cages are placed in

much larger bodies of water than those that would be used in a pond water production

system.

Flow through raceway production systems are used in areas where an abundance of fresh

water flow is available, such as near large rivers of springs. These set ups allow

continuous water flow through an open trough which contains provisions to constrain the

tilapia. Depending on the available rate of water volume flowing through the raceway,

the system may need to be mechanically supplemented to provide proper aeration for the

density of tilapia contained in the system.

The final category of aquaculture system, and the subject of this study, is a recirculating

system. These systems are used where water is not available in significant volume to use

a flow through model or in regions where the ambient climate is not suitable to permit

year-round production. Recirculating aquaculture systems may utilize earthen ponds,

3

concrete tank or some style of man-made raceway. The most advanced re-circulating

systems may be located in large greenhouses or other climate controlled indoor facilities

to aid in mediation of ambient temperatures. Water treatment in recirculating systems

must include mechanical aeration to add dissolved oxygen, mechanical filtration to

remove large particulate, biological filters to enhance nitrification and mechanical

heating and cooling capacity to control water temperature [4]. Figure 2 below shows

raceway style tanks used in a recirculating aquaculture facility while Figure 3 shows the

high density of fish

Figure 2: Raceway Style Tank for Recirculating Aquaculture System

Figure 3: Density of Fish in Raceway Style Tank

4

2. Theory

This project will explore the postulate that biomass should be accounted for when

performing heat transfer calculations for recirculating aquaculture water heating and

cooling systems. The basis for this postulate is the difference in energy required to heat

or cool fresh water in comparison to the energy required to heat or cool many commonly

farmed species of fish. Subsequently, the energy losses transferring heat into or out of

the fish and into the water will be explored. The commonly accepted specific heat of

fresh water at 30 °C is 4.18kJ/kg-K [1] while Table 1 below shows the thermal

properties (including specific heat) of several common species of animals that are grown

in aquaculture farms:

Table 1: Thermal Properties of Seafood [2]

Review of the information included in Table 1 shows that the specific heat of all

common species of animals grown in aquaculture farms is less than that of fresh water.

Therefore, the potential for optimization of heating or cooling loads required to maintain

a specific water temperature exists and is dependent upon the percentage of biomass in

the system coupled with the distribution pattern of the biomass.

2.1 Theoretical System

To test the postulate proposed in this report, a control system is proposed which

adequately represents current commercial practices. To accomplish this end, a raceway

style recirculating aquaculture system will be used to simulate a body of fresh water

5

used to grow tilapia. The raceway model used is a rectangular pool in which the length is

many times greater than the width and the depth of water is kept to a minimum. This

design is optimal for indoor recirculating aquaculture facilities as the geometry of the

pool provides a natural river-like flow pattern from one end of the raceway to the other

to aid in ensuring water replacement. The total volume of water that fills the raceway

must be cycled through filter, aeration, and temperature control systems at least once per

day to ensure sufficient water quality to allow for optimal growth conditions of the

aquaculture product. Figure 4 below shows the overall geometry that will be used for

this study:

Figure 4: Raceway Dimensions

The system represents a large section of a raceway pool; however it does not include the

ends of the raceway. This is done to simplify analysis be removing the need to consider

end affects of water discharge and return which would complicate analysis but not

provide added value to the investigation at hand.

6

3. Method

3.1 Analytical Model

This study will use the model proposed in Section 2 to analyze the heat transfer

mechanisms in the recirculating raceway. Figure 5 below shows how the heat transfer

mechanisms are applied in the system:

Figure 5: Heat Transfer Mechanisms

7

Figure 6: Heat Transfer Diagram – Without Biomass

8

Figure 7: Heat Transfer Diagram – With Biomass

3.1.1

Definition of System Parameters

Table 2: System Parameters

Variable

Tw-in

T∞

Tf

Tw-out

Tw

ρw

kw

kc

Cpw

Description

Water inlet temperature

Ambient air temperature

Fish temperature

Water outlet temperature

Log mean temperature

Density of water at 30° C

Thermal conductivity of water

Thermal conductivity of cement

Specific heat of water

9

Value

305.15

283.15

TBD

996.025

0.616

0.720

4.181

Unit

K

K

K

K

K

kg / m3

W/mK

W/mK

kJ / kg K

w

tw

Aw

8264 x 10-7

.010

100

Viscosity of water

Thickness of wall

Area of wall

Ns/m

m

m2

Table 3: Concentration of Tilapia in Raceway

Case 1 Case 2 Case 3 Case 4 Case 5

30%

40%

50%

60%

70%

𝑹𝒆 =

𝑫𝑯 =

3.1.2

Assumptions

3.1.3

Conductive Heat Transfer

𝑫𝑯 𝝆 𝒖𝒘

𝟒𝒂𝒃

Convective Heat Transfer

3.1.5

Radiation Heat Transfer

Eq. 2

𝟐𝒂+𝒃

𝒒𝒄𝒐𝒏𝒅 = −𝒌𝒄 × 𝟐 𝑨𝒘

3.1.4

Eq. 1

𝝁

𝑻∞ −𝑻𝒘

𝒕𝒘

Eq. 3

3.2 Computational Analysis

Computational analysis of the theoretical system is used to investigate the impact of fish

distribution in the raceway on the overall specific heat capacity of the system

10

4. Results

11

5. Discussion and Conclusion

12

6. References

[1]

Kathryn White, Brendan O’Neil, and Zdravka Tzankova, At a Crossroads: Will

Aquaculture Fulfill the Promise of the Blue Revolution? Copyright © 2004

[2]

LaDon Swann, A Basic Overview of Aquaculture History, Water Quality, Types

of Aquaculture, Production Methods, August 1992

[3]

Food and Agriculture Organization of the United Nations, faostat.fao.org,

Copyright © 2013

[4]

Claude E. Boyd, Farm-Level Issues in Aquaculture Certification: Tilapia

[X]

Transport Phenomena in Multiphase Systems; A. Faghri and Y. Zhang;

Copyright © 2006; Elsevier Inc. – Appendix B, Page 980, Table B.48

[X]

Measurement of Thermal Properties of Seafood; Radharkishnan, Sudhahrini;

Thesis Virginia Polytechnic Institute and State University June 26, 1997

[X]

Fundamentals of Heat and Mass Transfer; F. Incropera, D. Dewitt, T. Bergman,

A. Lavine; Copyright © 2007; John Wiley & Sons Inc. - XXXXXXX

13