BCD Technologies (Word - 2950KB)

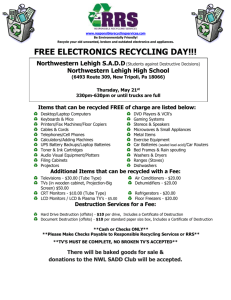

advertisement

BCD Technologies Pty Ltd Submission Department of Sustainability, Environment, Water, Population and Communities Consultation Paper on the Development of the Destruction of Waste ODS and SGG Program Table of Contents 1.0 Overview .......................................................................................................................... 3 2.0 Discussion......................................................................................................................... 4 3.0 A. Destruction ............................................................................................................................................ 4 B. Financial ................................................................................................................................................ 8 C. Reclamation and Recycling ................................................................................................................. 14 D. Gas Classification................................................................................................................................. 17 E. Administrative ..................................................................................................................................... 18 F. Miscellaneous ..................................................................................................................................... 19 Conclusions .................................................................................................................... 21 ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 2 of 21 1.0 Overview BCD Technologies Pty Ltd (herein referred to as BCD) are a division of Tox Free Solutions Limited (herein referred to as Toxfree). BCD Technologies is currently the only approved destruction facility for waste SGG and ODS gases in Australia These are primarily received through the Refrigerant Reclaim Australia and Refrigerant Recovery New Zealand Product Stewardship Schemes BCD is pleased to provide a submission considering the issues raised for Consultation on the Destruction of Waste ODS and SGGs Program. We agree that the Destruction Program must be designed to be simple and practical to manage and also highlight some of the environmental considerations for which we believe more stringent controls are required. Our company is a key stakeholder in the outcome of the program and we look forward to working with DSEWPaC to ensure the Destruction Program is developed to be pertinent to both the goals of the Clean Energy Future and to Industry. Our company; A locally run and managed company with the backing of a National Corporation and Interstate Network Established In-Flight Plasma Pyrolysis Process developed by CSIRO and used in Australia for SGG and ODS destruction for over 12 years. Small responsive Technical Team with strong working knowledge of waste SGG and ODS management and the Technical and Financial issues. Operators of SGG and ODS transfer and destruction facility with refrigerant analytical services. We readily invite DSEWPaC representatives to inspect our Facilities and use our experience and resources to assist with the development of a successful destruction program in conjunction with the other key stakeholders. Yours Sincerely, Daniel Allen Manager – Technical Services – East Coast BCD Technologies Pty Ltd & Thermal Treatment Solutions Pty Ltd Part of the Toxfree group 2.0 Discussion A. Destruction BCD has been using the Plascon® process developed by the CSIRO in Australia since the mid 1990’s for destruction of ODS and SGG gases and also for the destruction of high hazard liquid wastes such as polychlorinated biphenyls and organochlorine pesticides. Recently the company has also been destroying small quantities of SF6 gas on a contract basis. Our company views that Australia has a very strong refrigerant recovery program with established collection and administration networks and destruction by a process recognised internationally as world’s best practice. Need for destruction in coming years Australia has a bank of approximately thirteen thousand tonne of ODS refrigerants and twenty seven thousand tonne of SGG refrigerants over and above the five hundred tonne of ODS held by DSEWPaC for critical use and the SF6 gas in use in the electrical industry of which a portion cannot be reclaimed at end of life. Australia needs destruction capacity. However, the Australian market is a very small market on an annual basis with presently only some 500 tonne being returned for destruction at end of life. The total revenue for this market at the point of destruction in its present form is less than $3.5 Million dollars per annum and employs less than 15 people. Taken in isolation this total revenue figure and staff numbers is classified by most countries and definitions as a small business, except the ATO definition which includes revenue at less than $2 Million per annum. The APRA (Australian Prudential Regulatory Authority) whom controls financial institutions considers a small business as one with less than $50 Million per annum revenue. This is important as it means this market is very susceptible to significant legislative changes such as, in this instance, the carbon price reform affecting SGG and ODS gases under the Clean Energy Future Plan. There is a need for destruction of waste gases at end of life, this is a key commitment made by Australia under the Montreal and Kyoto protocols. It is not a market that can sustain significant competition or business risk and it is important that any destruction program under the Clean Energy Future recognises the importance of destruction of these substances and the scale of the market being affected. ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 4 of 21 Regardless of the effect of reclamation and recycling there will come a time when the residual in the existing bank of refrigerants will no longer be required to be utilised in systems, as refrigeration and air-conditioning technology progresses, and existing systems reach end of life by obsolescence. It is a criminal offence under the Ozone Protection and Synthetic Greenhouse Gas Management Act and Regulations to release ODS and SGG gas to atmosphere. Once the equipment is obsolete the gas will either be vented by the failure of old equipment or be recovered by conscientious licenced technicians to be returned for destruction. In terms of specific volumes and species this will depend on the effect of the destruction program incentives and the lifecycle profile of the refrigerant types. Requirements for an accredited destruction facility Regardless of market size consumers generally have a right to competition and this is fair. The implementation of a destruction program for SGG and ODS gas obviously sounds appealing and will likely spark interest from alternate destruction providers. What is important under a destruction program is to ensure that the environmental outcomes are not diminished and that only reputable and proven technologies and people are permitted to be part of this small but significant part of Australia’s international obligations and strong environmental reputation. Such a destruction facility is required to be licenced by a number of state administering authorities, for example, state environment protection authorities, workplace health and safety and council requirements as well as approval at a Federal level with licencing as an authorised refrigerant destruction facility, requirements for a halon special permit and individual refrigerant technician licencing. Outside of these exisiting requirements a principle policy should be utilised as an overarching goal. The current trend in Australia is derived from the American and European approach to permitting new technologies and facilities for hazardous industry. In Australia both EPA Victoria and the Western Australian Environmental Protection Authority have implemented the BACT (Best Available Control Technology) principle for assessing new technology and facility applications. This is summarised from an excerpt of the Western Australian Environmental Protection Authority Guidance Statement No. 55 “Implementing Best Practice in Proposals Submitted to the Environmental Impact Assessment Process”, Dec 2003; ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 5 of 21 Without going in to intricate detail of this principal, which is well documented, the key elements include; All relevant environmental quality standards must be met. Common pollutants should be controlled by adopting Best Practicable Measures (BPM) to protect the environment, Hazardous pollutants should be controlled to the Maximum extent Achievable (MEA), There is a responsibility not only to minimise adverse impacts, but also to improve the environment either directly or indirectly. Our company views that the BACT principal forms the basis of permitting accredited destruction (and reclamation) facilities. This could be incorporated as a requirement under the existing approvals process for refrigerant destruction facilities through the Ozone Protection and Synthetic Greenhouse Gas Management Act and Regulations. Such facilities should also be able to prove their financial viability given the relatively small nature of the destruction market, provide a process that can operate to keep up with the production requirements of the market and show traceability mechanisms for SGG’s and ODS’s from receipt to destruction. They should be assessed on the basis of requiring a strong working knowledge of SGG’s and ODS’s and the refrigeration and air-conditioning industry in order to maintain the strength of the current collection and destruction system. The Destruction Provider and broad coverage vs targeted services Our company views that definitions around broad coverage and/or targeted services are not specifically required. While a destruction provider could be the manager of a network of logistics to return waste gases this should be at the discretion of the provider rather than a requirement. We foresee that there is an opportunity for a destruction provider (whom we see as an aggregator) to operate as a direct aggregator, a broker or a combination thereof. We see that there is potential for a destruction facility to also be a destruction provider and offer this service as a conduit to their facility. We do not view that any area would be disadvantaged under this mechanism provided the hybrid model we describe under our financial considerations is adopted as this will provide incentive to the market to ensure that logistics networks operate nationally to maximise recovery for destruction. In particular, we see that different market sectors may require different approaches from an aggregator. The needs of the refrigerant sector are different than that of the fire protection sector (where critical use fire extinguishing agents need to be stocked for future use) and these are both different to sector covering SF6 in electrical equipment. Furthermore it is to be hoped that comprehensive de-manufacture of end-of-life ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 6 of 21 refrigerators and other sources of insulating foams can be carried out in the future in Australia, and this sector would again have separate issues related to aggregation and destruction. Therefore we would think that sector based aggregators be able to be licenced, rather than an aggregator being required to service all markets. Factors that should influence decision making on the type and scope of incentives for destruction The factors that should influence the destruction program are environmental best practice by providing a strong incentive to remove ozone depleting substances and high global warming potential (GWP) SGG’s from import and use in Australia. Australia has a strong economy and now receives from industry at least $190 million dollars per annum as a direct result of the import of SGG’s. The costs of funding destruction are only a small percentage of this which means the financial potential exists to really drive the shift to low GWP refrigerants. ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 7 of 21 B. Financial The primary aim of a financial mechanism implemented as part of an ODS and SGG destruction program is that it should be simple to implement and administrate while still achieving the goal of ensuring end of life refrigerant is returned for destruction. In an ideal economy a market-based GWP-based incentive would be the most suitable however this is not directly suitable to the Australian ODS and SGG destruction market for a number of reasons. We propose a variation of the Hybrid Model described in the consultation paper and discuss some of the other financial issues. Financial Model – Our View Our view is that an alternative hybrid model should apply based on covering the costs of destruction plus GWP additional to this. A hybrid model should not be the model described in Option 2 Alternative B of the consultation paper which proposed covering the costs of destruction and a differential percentage of GWP. We view that the GWP calculation basis for providing a destruction incentive over and above the cost of destruction should be based on the average species and volume of refrigerant in the Australian bank of refrigerants being the most stable and reliable form of data for this calculation. Such a hybrid model would ensure that the base cost of destruction is covered regardless of the price of carbon and would provide enough of an incentive to ensure that end of life refrigerant continues to be returned for destruction as well as supporting recycling and reclamation of SGG’s. However, complimentary to such a financial model greater regulatory support will be required to ensure that harmful ODS gases such as R22 are consigned for destruction rather than reclamation processes. As refrigerants are primarily returned as mixtures of waste gases it is not practical to pay a destruction rebate based on the specific GWP of each species returned except where a significant quantity of a specific gas is returned. The financial model we propose therefore assumes an average GWP to be applied as the incentive for any waste gas returned to be based on the mass of waste gas returned. This assumes that the waste mixture of gases as a whole will follow the trend of composition of those in the bank of refrigerants with the separate fixed price for ODS being covered under the existing overall cost of destruction. An example of the GWP calculation based on the table from the consultation paper entitled “The bank of ODS and SGGs by gas type” shows what this GWP incentive would be based on the GWP and levy values is shown; ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 8 of 21 Mean GWP based on Leviable Refrigerants in the Australian Bank Species % of Bank Levy per kg GWP HFC-410A 22% $ 40.00 1725 HFC-407C 4% $ 35.00 1526 HFC-404A 9% $ 75.00 3260 HFC-134a 32% $ 30.00 1300 Mean: $ 26.55 1150 Then, using the cost of destruction outlined in the consultation paper we provide an example payment under the scheme; Example payment structure based on one kilogram of mixed waste refrigerant returned for destruction Entity Value Notes Destruction Provider and Destruction Facility Combined Total $13.50 Current cost of destruction as outlined in the consultation paper Wholesaler and Recoverer Combined Total $10.50 Current incentive payments as outlined in the consultation paper $26.55 Mean GWP based on Leviable Refrigerants in the Australian Bank Total Destruction Incentive: $50.55 Based on consultation paper and example calculation Consideration of Alternate Financial Models Option One – Alternative A – Efficient Cost of Destruction A flat rate payment scheme works well when it is the only financial factor and is directly linked to a single revenue stream such as a fixed import levy. Under a scheme that puts a high price on the import of refrigerants without balancing this at the point of return of the refrigerant for destruction at end of life there becomes little incentive to return gas for destruction unless compliance is more heavily enforced at a contractor level. The concept of a flat rate payment works because it is simple to administrate. However it will severely affect the destruction industry and the capacity and quality of this essential service, it may even lead to mothballing of destruction facilities given the small size of the market, unless the flat rate is sufficiently high to encourage ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 9 of 21 sustained destruction of ODS and end of life gases in conjunction with regulation and compliance to remove ODS from service whilst not precluding the recycling of suitable SGG gases. Option One – Alternative B – GWP-Based Flat Rate This option would need to be based on the average GWP of all ODS and SGG in the Australian bank of refrigerants. This would provide a workable interim solution however, as the composition of the bank trends away from high GWP refrigerants and the incentive moves to a market-based structure it has the analogous inherent risks to Option Two – Alternative A as discussed below. Option Two – Alternative A – GWP Incentive Payment This is the highest risk option proposed and should not be considered at all in our opinion. It will provide the correct incentive for destruction in the early years of the program however, if the open market trends downwards rapidly as is the current case globally and exemplified by the dramatic drop in value of emission abatement units in New Zealand from highs of over $20 per unit to less than $2 per unit, then there will be no money to fund destruction. The risk is that when this becomes a market-driven commodity it becomes a short-term solution to a longterm problem and ultimately dis-incentivises destruction unless an alternate financial support mechanism also exists. Option Two – Alternative B – Hybrid Model This is the most workable of the options proposed however we believe it could be improved upon as we have proposed in our alternative hybrid model. Allocated funding Our company wishes to raise some additional points around the allocation of funding. We understand from the consultation paper that the budget allocated for the destruction program is ranges from $23.4-37.5M per annum over first 3 years compared to a budgeted $190M revenue. We also understand that the revenue derived from the price applied to the import of SGG’s in bulk is not ring-fenced within the management of ozone depleting substances and synthetic greenhouse gases but is rather to general government funds. This is however a large amount of revenue incoming that is directly related to the management of ozone depleting substances and synthetic greenhouse gases and we view that the budget should reflect the goals of ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 10 of 21 the Clean Energy Future to promote change to low GWP gases. This will only happen if a strong incentive is provided to recycle low GWP SGG’s, destroy ODS substances (the most prevalent being R22) and create greater compliance and awareness of the management of ODS and SGG substances. Using a waste analogy, where landfill levies are collected in most states to promote a diversion from landfill we see a success story where waste funds are most effective when high levies are imposed and the funds derived from these levies are maintained (ring-fenced) in the government department in which they are collected. The Victorian EPA collects the highest waste levies in Australia with the cost of landfill in Victoria being up to $760 per tonne as a result as opposed to a maximum of around $70 per tonne in Queensland which has no waste levy. There is no incentive in Queensland to avoid landfill resulting in its widespread use and lack of incentive for the waste industry to develop new technologies and awareness of waste diversion from landfill. In Victoria the waste levy and fund are driving significant diversion from landfill and are providing a strong pipeline of funding for both compliance enforcement and to incentivise industry to develop a range of alternate waste treatment technologies. Funding in the form of grants is provided to businesses establishing treatment processes and technologies that prove a diversion of waste from Victoria’s landfills. The same ring-fence principal (to a greater degree than presently budgeted) should apply to the ODS and SGG industry with the money derived from the charge payable on import of these gases. At present the budget allocation only seems to cover the base cost of destruction, a small amount of risk and some administrative cost allowances. We view that the DSEWPaC has an opportunity to provide a small amount of additional funding to support any or all of the following which we believe would strengthen the industry; Compliance enforcement of emitters of end of life gases (including contractors, councils, demolition companies, car crushing plants, refrigerators and air-conditioners at scrap yards and landfills). National awareness campaigns targeted at householders and industry contractors. Grants for development of improved environmental outcome-based low GWP refrigeration alternatives and technologies to reduce leakage rates, promote environmentally sound destruction of ODS and end of life gases and support reclamation of low-GWP refrigerants. Funding for product stewardship of end of life refrigerators, air-conditioners and vehicles. ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 11 of 21 Financial mechanisms for co-contamination of waste gas streams (Hydrocarbons, CO2, NH3) One aspect of any destruction program will be the management of the mixtures of waste gas returned of which, under the present product stewardship scheme, the whole mass of gas returned is paid for destruction or as a contractor rebate even though the composition may have a small amount of waste hydrocarbon and other non-ODS non-SGG co-contaminants. Under any scheme significant co-contamination must be traced back to the contractor by having mechanisms of traceability through the system coupled with education and an enforcement system to first work with contractors then take increasing action if co-contamination of waste gas streams at any significant level continues. However, the scheme must continue to pay on the whole of the mass of the waste gas returned otherwise the efficient cost of destruction will increase to compensate for this. We are unsure whether this has been considered to date and suggest it is an important consideration of the destruction program. Inclusion of high GWP gases High GWP gases should be included in any destruction scheme. For refrigerants our alternative hybrid model works for these gases except SF6 which is discussed below. The financial risk is low and can be controlled by ensuring licensed contractors are used and that traceability mechanisms exist through the chain. Any significant quantity of high GWP gases would then raise suspicion that could be traced to a contractor level to follow up suspected fraud or theft. SF6 SF6 should be included in the destruction scheme and is in a different category to the majority of SGG substances by virtue of its almost exclusive use to the power generation and supply industry which are predominantly controlled by state-owned utilities. We believe that SF6 could have a full GWP incentive applied which, due to the GWP of SF6 being 23,900:1 would still provide enough incentive to cover the cost of destruction and cover the market-based risk of carbon trading on a free market. With suitable tracking and control our company believes that there would be only small quantities of this gas received for destruction with the majority being recycled. SF6 continues to be used preferentially to oil-based insulators in power supply and distribution. The high cost of purchase means this gas will be preferentially recycled. It is suited to recycling as it is a gas used and collected in isolation from other gases so is normally returned as a single gas mixture with moisture, air and decomposition products as the only contaminants. Because of this it can largely be recycled and produces only a small fraction of contaminated gas that requires destruction. ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 12 of 21 Presently our facility destroys around 250kg per annum of SF6 thus, based on the quantities involved there would be again suspicion raised around any significant quantity. Additionally, any theft or fraud would contain an element of danger to the thief as the gas is primarily retained in high-voltage switchgear controlled by state owned enterprises. These state owned enterprises have group environmental coordinators and strict operating procedures and policies that do not tolerate non-compliance or suspicion of theft/fraud. ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 13 of 21 C. Reclamation and Recycling Overview Some key focal points of the Clean Energy Future Plan are to have an equivalent carbon price that aims to; Increase recycling of SGG’s and, Encourage a switch to purpose-designed equipment using lower GWP gases. Inherent in these focal points is a recognition that SGG’s have a lower environmental risk profile than their ODS predecessors. Our company views that the environmental risk associated with recycling of most SGG’s is relatively low due to the following reasons; Most SGG’s are installed in modern equipment which has lower leakage potential than older ODSbased systems. SGG’s generally have very low ozone depleting potential. The majority of these gases are imported and are likely to continue to be until the switch to lower GWP alternatives makes the need for such gases and the equipment they are used in redundant. What the Clean Energy Future Plan does not address and which our company believes is a perverse outcome of applying a carbon price to SGG’s and not to ODS substances is that the primary gases targeted for reclamation and recycling will be ODS and not SGG as intended. Effect of destruction incentives on reclamation. Our company believes that a destruction incentive can be set at a high level as outlined in our alternative hybrid model and that this will not affect the viability of reclamation for low-GWP SGG’s in the Australian market. Having a low destruction incentive while a high price is paid on import (that flows through to the consumer on top of the base price of the refrigerant) will significantly tip the balance toward reclamation and may make destruction commercially unviable. Reclamation while a GWP equivalent price is paid on the import of SGG’s has a double incentive in that the GWP equivalent price is not paid for the reclaimed product and the underlying market value of the waste gas can also be charged. While there is still an inherent capital cost and direct operating cost to the process the end result is a product that, while demand exists, will provide a greater return to a commercial entity than to send the waste gas for destruction. ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 14 of 21 It is therefore important to ensure that a significant incentive remains to return waste gas for destruction coupled with greater compliance of the industry. This will ensure that multiple industries thrive and that the environmental aims of the Montreal and Kyoto protocols are adhered to. The R22 Environmental Issue ODS gases and specifically the most significant ODS presently in use, the HCFC R22 are being phased out globally under the Montreal Protocol. This is because they have both a strong deleterious effect on the ozone layer and also typically have high global warming potentials. In short they are internationally recognised as environmentally harmful substances that should not be permitted for widespread use. The problem is that the distinction between ODS gases and SGG’s has become blurred and ODS gases have been caught up in the attitude that has become prevalent in our society that recycling and reclamation for reuse are favourable attributes to apply to waste substances. For most materials this is true but certainly not for ODS gases of which the most prolific in the Australian bank of air-conditioning and refrigeration equipment is R22, comprising some 30% or approximately twelve thousand tonnes of environmentally harmful gas still in use in Australia. Our company puts forward that recycling and reclamation of ODS gases and specifically R22 should be banned concurrently to the destruction program for the following reasons; ODS’s and R22 are internationally recognised as harmful environmental gases to be phased out under the Montreal Protocol By allowing import, use and reclamation until at least 2030 Australia will be 15 years behind other world leaders in this area, such as the United Kingdom, whom have completely banned imports and use of virgin HCFCs and have also banned the use of recycled or reclaimed HCFC’s (R22) from 2015(The EC Ozone Regulation Legislative Update and Strategies for HCFC Phase-out Information Sheet RAC 8 – R22 Phase-out) . R22 systems are typically older air-conditioning and refrigeration systems. To allow recycling and reclamation back in to such systems increases the risk of their emission causing environmental harm at end of life as these systems are more likely to be prone to failure and leakage. There is no need to prolong the use of R22. The refrigeration and air-conditioning industry has been planning its obsolescence for some time and, as far as we are aware, R22 is not installed in systems that have critical use. If critical use is required, such as the present situation in Australia where halon ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 15 of 21 is stored in controlled quantity for fire-fighting applications in air-craft and defence force use, then such use should be separately legislated and controlled. It is not required for domestic purposes. There are drop-in replacement gases for R22 systems available. Although these replacements have similar GWP to R22, the fact that they have zero ODP makes them vastly superior to R22 where it is not economic to replace the R22-based system with a system designed around non-ODS refrigerants. Legislative control and compliance enforcement Legislation coupled with compliance enforcement should be strengthened to control and prevent reclamation and recycling of ODS gases. Specifically reclamation and recycling facilities and technicians must be licenced and controlled to the same degree as destruction facilities to ensure they are only managing SGG gases and that the gases being put back in to air-conditioning and refrigeration systems are pure to ARI 700 standard and only being replaced in to systems with little or no risk of leakage. Our company proposes that legislative and compliance controls and greater funding for the compliance enforcement of the refrigeration and air-conditioning industry be considered concurrently to the destruction program and that funding be allocated for these controls. Industry agrees with us Some recent comments from the December 2012 issue of Climate Control News including a roundtable discussion by other key industry stakeholders also support the risks involved in encouraging recycling and reclamation; Michael Bennett (RRA): “the potential for systems to be contaminated by impure refrigerant is real, and there is a danger this will be widespread.” Ian Stangroome (VASA): “The potential for contamination of the refrigerant pool in the automotive sector is extreme.” Glenn Evans (ARC): “Fake refrigerant isn’t the only new danger faced by technicians as the home-grown problem of impure, contaminated and flammable mixtures becomes more prevalent.” ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 16 of 21 D. Gas Classification Identification of species before payment is made. The foremost issue regarding gas classification is safety to contractors on consolidation and processing of waste gases. Our company sees gas classification working by two distinct analytical methods being a tier 1 classification at an aggregator’s facility and a tier 2 classification at or before delivery to a destruction facility. Tier 1 we see as being an initial safety check at the aggregator’s facility, the aggregator being the entity whom takes the small recovery cylinders from technicians and consolidates these in to half tonne or one tonne vessels for consignment for destruction. At a tier one level it is important to conduct a generic identification of the composition of the cylinder by use of a small hand held gas analyser or similar. This will assist in the determination of the presence of ODS and SGG gases and may also serve to identify any flammable substances present. Once the aggregator is satisfied the cylinder is suitable (safe) to consolidate they will decant these with the contents of other small cylinders in to the larger vessel. Tier 2 we see as being a comprehensive assessment of the contents of a half-tonne or one tonne vessel by gas chromatography. Our destruction facility currently operates a laboratory for this purpose and we know of at least one other such laboratory in Australia thus an aggregator could send a sample to a third party laboratory and provide a cylinder with corresponding analysis to the destruction facility or could send the cylinder to the destruction facility directly whom could conduct the analysis on behalf of the aggregator. At a tier 1 level identification of species before payment is made is probably not practical. It is possible at a tier 2 level however is probably not necessary under a hybrid model that pays destruction costs plus GWP. Under this circumstance the analysis would be primarily be used to trace contamination and keep industry honest and provide data to show the trends in the type of SGG and ODS gases being removed from service nationally. NATA accreditation Our company believes it should be a requirement that companies conducting gas analysis be accredited to the Standard ISO/IEC 17025:2005. Presently the Australian accreditation to this analytical quality standard is conducted by NATA. ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 17 of 21 E. Administrative How would the hybrid model work? The key to a successful destruction program is to ensure refrigeration and air conditioning contractors and wholesalers are encouraged to return end of life refrigerant to the program. In order for this to happen incentives need to pass through the chain of wholesaler (aggregator) to technician as currently occurs through the successful Refrigerant Reclaim Australia product stewardship scheme. Under a hybrid model where the cost of destruction plus a full GWP incentive is paid to the destruction facility or destruction provider it would be imperative that as much of this GWP incentive as possible is passed back through the chain. Our company envisages that cylinders would be returned to an aggregator or would be passed from an aggregator to the destruction facility. The aggregator would be required to have traceablility mechanisms to determine the origin of each unit of gas they have aggregated and would likely pay a percentage of the mean GWP of the Australian installed bank of refrigerants to their contractors on return of waste gas. An aggregator would use a hand held gas analyser or similar to determine the generic composition of each cylinder returned prior to aggregating these in larger cylinders. On receipt of aggregated (bulk) deliveries of gas to the destruction facility our company envisages a percentage as close to the full GWP as possible (based on the average bank value, full GWP less future changes in operating costs not covered by the efficient cost of destruction) would be paid to the aggregator in addition to the efficient cost of destruction rebate. The destruction facility would analyse by gas chromatography each bulk cylinder received and determine the composition of the gas. Where any trend showed significant percentages of non-SGG and non-ODS gases the traceability back through the aggregator becomes of importance. In such circumstances our company envisages the aggregator would then, on receipt of cylinders from the same providers to the contaminated cylinder would organise individual samples for analysis by gas chromatography and deduct the cost of this testing from the rebate (GWP incentive) paid to the contractor. This would act to ensure that only eligible gases are returned to the destruction program and act as a key driver for technicians to improve their separation of gases at the point of collection. ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 18 of 21 Annual review mechanism Our company agrees that an annual review mechanism is imperative. We believe the hybrid model based on costs plus GWP is workable and are keen to be a key driver to the success of the destruction program however this is also a significant change for industry that has potential to disrupt the established networks and supply chain under the current product stewardship scheme. Our company is happy to provide a representative to sit on an annual review panel to provide key operational views regarding the destruction program. F. Miscellaneous Potential for increased theft/fraud Our company believes the potential for theft/fraud has already been established by introduction of a GWP equivalent levy on the import of SGG’s. Presently refrigerant could be stolen from existing equipment and onsold to consumers as new refrigerant. Traceability and greater compliance enforcement than is currently present in the Australian air conditioning and refrigeration industry is imperative. This will assist in minimising the potential for stolen refrigerant to be returned to the program. Non-SGG and non-ODS refrigerant “spiking” of gas to be returned can be countered by the gas classification regime described in this submission. Regarding high GWP gases such as SF6 this is particularly pertinent as we would not expect greater than a few hundred kilograms to be returned for destruction each year. Any significant quantity of such gas would automatically trigger alarm bells. Refrigerators and AC units and blowing agent foams Our company believes the same rebate under the destruction program should apply to SGG and ODS gases recovered from end of life air conditioning units and blowing foams. These two items are very poorly managed in Australia at present. However, the destruction program itself will not provide enough incentive to encourage widespread recycling of these items. The cost to properly recycle a refrigerator is not covered by a destruction incentive alone. Instead they must also be subject to a product stewardship scheme. We recommend these items be referred to the Product Stewardship Advisory Group. ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 19 of 21 Internationally such schemes have worked where a levy, for example twenty dollars on the manufacture or import of each unit is applied. This is used to fund recovery at end of life. In such environments facilities have been established that shred the units in a contained atmosphere to collect the waste ODS and SGG gases followed by a process whereby each of the components of the unit are separated and recycled as far as practicable. The cost to the end user is negligible, additional jobs are created and a strong environmental outcome is achieved. ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 20 of 21 3.0 Conclusions In summary our main points regarding the ODS and SGG destruction program and the related issues are; We have put forward an alternative hybrid model that we believe is workable based on covering the efficient destruction cost and paying additionally an average GWP of the SGG refrigerants installed in the Australian refrigerant bank. High GWP SGG’s should be included in the program and there is potential to separate SF6 by virtue of its industry and pay a full GWP for this gas. Accreditation and control of destruction facilities, reclamation facilities, recycling facilities and processes and analytical laboratories are imperative to the process. Environmentally harmful ODS substances such as the prolific R22 should be banned as well as use of reclaimed R22 concurrent to the destruction program. Additional funding and regulation should be provided to compliance, national awareness and industry grants to support the Clean Energy Future. Product Stewardship should be recommended for refrigerators, air-conditioning units and the automotive industry. ODS SGG Destruction Program | DSEWPaC BCD Technologies Pty Ltd | Submission Dec 12 Page 21 of 21