maitland/5231/H10Alkalis and Detergents

advertisement

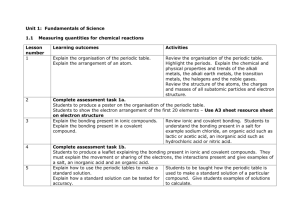

H10 Alkalis and Detergents Industrial processes are continually being improved to make them more efficient or environmentally safe. This chapter investigates the industrial production of sodium hydroxide and sodium carbonate. Properties of sodium hydroxide Uses for sodium hydroxide Sodium hydroxide is used in the manufacture of: Soap and other detergents Rayon and other plastics Paper Oven and drain cleaners Very soluble in water Very strong base, completely ionising into Na+ and OHions in aqueous solution Sodium hydroxide is also used in the manufacture of: Extraction of alumina from bauxite Removal of H2S and SO2 in the processing of natural gas and oil. Galvanic cell Device in which a chemical reaction generates electricity by converting chemical energy to electrical energy. Electrolysis Process in which electrical energy is converted to chemical energy and therefore to bring about chemical change. Electrolytic cell A cell in which electrolysis is carried out Industrial preparation of sodium hydroxide Sodium hydroxide is made industrially by electrolysing a concentrated sodium chloride solution (brine). 2NaCl(aq) + 2H2O(l) 2NaOH(aq) + Cl2(g) + H2(g) Three different electrolytic cells have been used over the last 100 years. Diaphragm cell Mercury cell Membrane cell Diaphragm cell Salt bridge: Anode: Cathode: Asbestos diaphragm Titanium Iron mesh Oxidation reaction 2Cl- Cl2 + 2e- Reduction reaction 2H2O + 2e- H2 + 2OH- Advantages Produces large quantities of sodium hydroxide and chlorine Reasonable cost Acceptable levels of purity Disadvantages Small amount of chloride in the sodium hydroxide Health and environmental problems associated with making and using the asbestos diaphragms There may be hypochlorite, ClO-, (a strong oxidant) in the waste brine solution Mercury cell Salt bridge: None, sodium metal is drained off as a mercury amalgam. Anode: Cathode: Titanium Liquid mercury Oxidation reaction 2Cl- Reduction reaction Na+ + e- Cl2 + 2eNa (dissolved in Hg) Advantages Produces very pure sodium hydroxide Avoids using mercury Disadvantage Loss of mercury to the environment Membrane cell Salt bridge: Anode: Cathode: Polytetrafluoroethylene (PTFE) diaphragm Titanium Iron mesh Oxidation reaction 2Cl- Cl2 + 2e- Reduction reaction 2H2O + 2e- H2 + 2OH- Advantages Virtually pure sodium hydroxide No asbestos or mercury No hypochlorite, ClO-, (a strong oxidant) in the waste brine solution Disadvantages Not known as yet Electrolysis of sodium chloride under different conditions Faraday constant (Insert Conquering Chemistry HSC page 346 Table 10.1) Quantity of electricity carried by one mole of electrons. 96 500coulombs per mole (C mol-1) Coulomb Amount of charge involved when a current of one ampere flows for one second. Q = It Hydrolysis Reaction between a compound and water. Saponification Fats and oils Soap Reaction between an ester and hydroxide ion to form an alcohol and a carboxylate anion. Saponification is the hydrolysis of an ester under alkaline conditions. Esters of glycerol (1, 2, 3-propanetriol) Each glycerol reacts with three fatty acid molecules to form a triglyceride. Saturated fatty acids lead to solid fats Unsaturated fatty acids lead to liquid oils Soluble salt of a fatty acid, most commonly sodium tristearate or sodium palmitate. Made by the saponification of fats and oils. Surfactant Surface acting substance Substance that decreases the surface tension of water or, alternatively, “solubilizes” dirt and grease. Consists of a hydrophilic carboxylate ion at one end of the molecule attached to a hydrophobic hydrocarbon chain. Synthetic surfactants do not form precipitates with magnesium and calcium ions and consequently can be used with hard water. Emulsions Dispersion of small droplets of one liquid throughout another liquid. Different classes of surfactants (Insert Conquering Chemistry HSC page 356 Table 10.3) Environmental impact of soaps and detergents Solvay process Soaps are biodegradable Earliest synthetic surfactants (anionic branched-chain alkylbenzene sulfonates) were not biodegradable. Later linear-chain alkylbenzene sulfonates have a similar biodegradability to that of soaps. The phosphate content of washing powders and liquids is the major environmental concern with detergents. The key steps in the Solvay process used to manufacture sodium carbonate are Saturate a concentrated brine solution with ammonia. Bubble carbon dioxide through this to form a precipitate of sodium hydrogen carbonate Filter off the sodium hydrogen carbonate Heat the sodium hydrogen carbonate to form sodium carbonate Regenerate the ammonia from the filtrate in the third step. Environmental issues associated with the Solvay process include: Disposal of calcium chloride Loss of ammonia Waste heat Mining