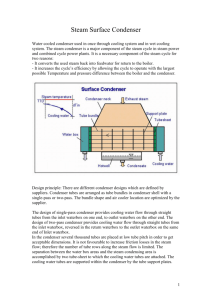

Steam Surface Condenser Design

advertisement

Memo To: Daniel Pope From: Josh Stratton Date: 2/9/2016 Re: Steam Surface Condenser Design Steam Surface Condenser Design A condenser of a steam power plant with a thermal efficiency of 40% that generates 10 MW of net electric power is to be designed. The steam enters the condenser as saturated vapor at 10 kPa and is to be condensed outside horizontal tubes through which cooling water from the St. Louis River flows. The temperature rise of the cooling water is limited to 8 degree Celsius and the velocity of the cooling water pipes is limited to 6 m/s. A schematic, to the right, shows the connections of the steam condenser being designed. The cooling water was taken from the mouth of the St. Louis River, which is at an average 4 degrees Celsius, year around [1]. The pipe material was chosen to be series “L” copper with an outside diameter of ¾” [2]. The size of the copper tubing was chosen from comparing the pumping power and the volume required for a rectangular cross sectional arrangement of the cooling pipes, described in Appendix 3. The arrangement of tubes was determined to be 19 vertical tubes and 32 horizontal tubes with a spacing of ¾”, to provide a realistic 4 ft. H x 2.5 ft. W x 10.5 ft. L design. 1 Steam In Ø .75in. .75in. .75in. N=19 N=32 Water Out Page 2