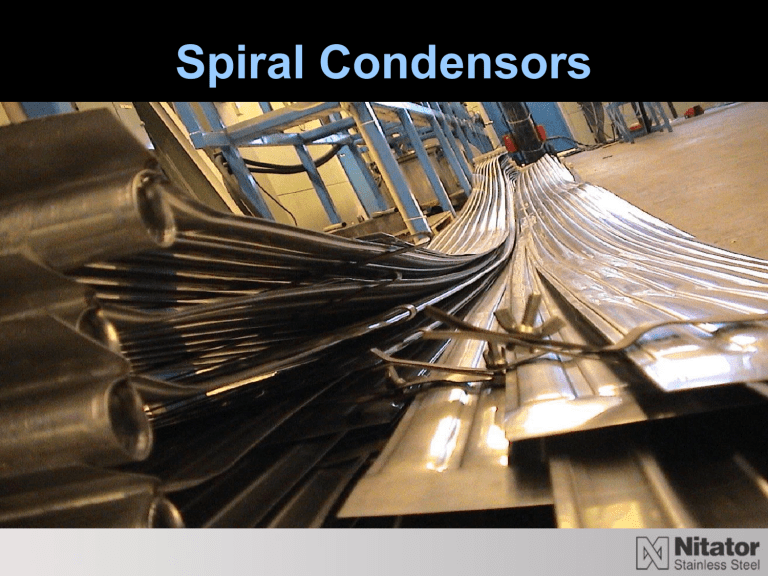

Spiral_Condensors - Nitator Stainless Steel AB

Spiral Condensors

Working Principle

The Spiral Condensor consists of two sheets stainless steel strips which have been wounded from the centre

Working Principle

The cooling medium consequently flows spirally through the seal welded channels while the vapour steam or gas to be condensed flows through the open spiral body

Special Features

The Spiral Condensor is designed with separate channels in order to equally spread and distribute the cooling water out into the periphery

Special Features

This means that the

Spiral Condenser is filled up very quickly and that the temperature is effectively spread at high turbulance, still with a low pressure drop, which is important to minimise pump effort

Pressure drop for water

450

400

350

300

250

200

150

100

50

0

0 3 4 5 6 7 8 9 10 11 12 13 14 15 m3/h

3 m2

6 m2

Special Features

The plate thickness is only 0.7 mm and the secret is based in the mantle profile which have been developed during the past 25 years of design and production of more than 3000 units

3 m 2 6 m 2

Areas Of Use

DEAERATION OF LIQUIDS

DAIRY PRODUCTS

BEVERAGES

MILK

OTHERS

JUICE

KETCHUP

Technical Specifications

3 m 2 Subject 6 m 2

Heat exchange surface, m 2 3.0

6.0

Through passage steam area, m 2

Condensed steam capacity at 60 0 C, kg/h

Cooling water capacity, m 3 /h

Maximum pressure, kPa

Water inlet connection,

mm

Water outlet connection,

mm

Height, mm

0.02

300

8.5

500

38

51

572

0.02

500

15

500

38

51

933

Width, mm 392 392