Biomass Energy Curriculum Part Three

advertisement

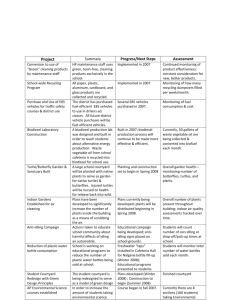

Hot Topics Workshop: Table of Contents Biofuels ........................................................................................................................................................................................ 4 ETHANOL .................................................................................................................................................................................... 4 MODEL 1: Ethanol Molecule ........................................................................................................................................... 4 MODEL 2: Sugar versus Corn versus Cellulosic Ethanol .................................................................................... 5 MODEL 3: Plant Cell Walls: Key to Understanding Cellulosic Biomass ........................................................ 6 MODEL 4: Step 1: Pretreatment with Enzymes ..................................................................................................... 7 MODEL 5: Step 2: Hydrolysis ........................................................................................................................................ 8 MODEL 6: Step 3: Fermentation to Ethanol............................................................................................................ 8 MODEL 7: Carbon Cycle and Ethanol.......................................................................................................................... 9 MODEL 8: Advantages and Disadvantages of Ethanol ...................................................................................... 10 Investigating Ethanol as a Fuel ........................................................................................................................................ 11 Protocol: Composition of Fuels ................................................................................................................................... 11 Protocol: Ethanol from Corn ........................................................................................................................................ 13 Part I: ............................................................................................................................................................. 13 Part II: ........................................................................................................................................................... 15 BIODIESEL ................................................................................................................................................................................ 18 MODEL 1: Internal Combustion, Four-Stroke Gasoline Engine ..................................................................... 18 MODEL 2: Four-Stroke Diesel Engine....................................................................................................................... 19 MODEL 3: Gas Engine versus Diesel Engine .......................................................................................................... 19 MODEL 4: Diesel Fuel versus Gasoline .................................................................................................................... 20 MODEL 5: Fat: The Common Thread of Biodiesels ............................................................................................. 21 MODEL 6: Transesterification: Making Biodiesel from Oils............................................................................ 22 MODEL 7: Basic Technology in Biodiesel Process .............................................................................................. 23 MODEL 8: Microalgal Oil for Biodiesel ..................................................................................................................... 24 MODEL 9: Process of Algal Biodiesel Production ................................................................................................ 25 Research at WUSTL.................................................................................................................................. 25 Investigating Biodiesel Properties, Production and Efficiency Protocol: Determining Catalyst Needed for Biodiesel Production .................................................................................................................................... 26 Protocol: Properties of Various Cooking Oils ........................................................................................................ 27 Part 1: Density of various oils ............................................................................................................. 27 Part 2: Freezing point and melting point of various cooking oils ......................................... 30 Part 1: Synthesis of biodiesel .............................................................................................................. 34 Part 2: Separation and purification of biodiesel ........................................................................... 35 Part 1: Density and freezing/melting point of biodiesel .......................................................... 37 Part 2: Heat of combustion of biodiesel ........................................................................................... 41 MODEL 2: Renewable Bioproducts ........................................................................................................................... 45 MODEL 3: Polymerization ............................................................................................................................................. 46 Investigating Biodegradables Protocol: Making and Testing Corn Plastic ............................................... 47 Culminating Project .............................................................................................................................................................. 49 Biomass Energy Expert Task: ...................................................................................................................................... 50 Science Poster Rubric ............................................................................................................................. 53 Biomass Resources ............................................................................................................................................................... 54 Biofuels WHY? Biofuels are transportation fuels, like ethanol and biodiesel, that are made from biomass materials. These fuels are usually blended with petroleum fuels – gasoline and diesel fuel, but they can also be used on their own. Using ethanol or biodiesel means we don’t burn quite as much fossil fuel. This means that we have cleaner-burning fuels, producing fewer air pollutants and reducing our carbon footprint. In this section we focus on both ethanol and biodiesel, what they are, how they are made, current research efforts to increase efficiency and comparative analysis of the two biofuel technologies. ETHANOL MODEL 1: Ethanol Molecule What are the names and numbers of atoms that make up ethanol? What is the formula for ethanol? The atoms that are circled in red are called a functional group. What are these atoms? This functional group makes ethanol an alcohol. Based on this Model, circle the molecules below that are alcohols. MODEL 2: Sugar versus Corn versus Cellulosic Ethanol Based on Model 2, what are some examples of feedstock that can make ethanol from sugar? Based on Model 2, what are some examples of feedstock that can make ethanol from starch? Based on Model 2, what are some examples of feedstock that can make ethanol from cellulosic biomass? What three technologies are necessary for making cellulosic biomass? What technology is needed for all three types of ethanol production? Based on Model 2, what are the current sources for ethanol production? Based on Model 2, predict where current scientific research is focused. MODEL 3: Plant Cell Walls: Key to Understanding Cellulosic Biomass What are the two types of cell walls present in the plant cell? Where are the cellulose microfibrils located? Each microfibril structure contains chains of glucose molecules. Chains of repeating molecules of glucose molecules make up cellulose. Based on this information, circle one glucose molecule in the cellulose molecule pictured below: On this diagram, label the areas where biomass, starch and sugar come into the process of ethanol production. At what point in the process is cellulose released? What is the original source of energy that is eventually transformed into a biofuel? MODEL 4: Step 1: Pretreatment with Enzymes What is happening in this step? Based on this Model and your knowledge of plant cell walls, what is the purpose of this step? MODEL 5: Step 2: Hydrolysis Enzymes are used to allow for chemical reactions to take place quickly. Enzyme names end in “ase.” What is the name of the enzyme? What molecule does this enzyme work on? Is this enzyme used to build something (synthesis) or to break something apart (degradation)? MODEL 6: Step 3: Fermentation to Ethanol What sugars do the microbes ferment? What are the steps of this process? How is the ethanol purified? Where does this process take place? MODEL 7: Carbon Cycle and Ethanol What is the source of energy in this process? Based on this Model, what are the inputs into the factory to make ethanol? Based on this Model, what are the outputs into the factory? How does this diagram explain why ethanol production is carbon neutral? In other words, even though carbon dioxide is being produced, what in this process uses this carbon dioxide? MODEL 8: Advantages and Disadvantages of Ethanol Based on this cartoon and the diagram of the carbon cycle what are the advantages and disadvantages of ethanol? Take a position. Do you believe that the use of ethanol is more beneficial or less beneficial? Support your reasoning. Investigating Ethanol as a Fuel Protocol: Composition of Fuels Background: In chemistry, the names of compounds with the same functional group often end with the same suffix (i.e., ethanol ends in –ol because it is an alcohol!). The prefixes in the names refer to the number of carbon atoms in the formula. Materials: Toothpicks Three colors of modeling clay Procedure: 1. Write the molecular formula for the following: a. Methane b. Propane c. Ethanol d. Butanol 2. Use one color of clay for carbon, one for hydrogen and another for oxygen. Create 3D models of the formulas of methane, propane, ethanol, and butanol. Also create a model of O2. 3. Draw and label your models in the space below. 4. When methane burns, it combines with oxygen to form carbon dioxide and water. This reaction is NOT balanced, but indicates the substances necessary for methane to burn and the products formed. The number of molecules in the system remains constant, although molecules can be changed from one form to another or transferred from one object to another. This means the same number of each atom must be present on each side. 5. How many Carbon atoms are on the left side? How many carbons are on the right side? Are the Oxygen atoms balanced? 6. How many Hydrogen atoms are on the left side? How many are on the right side? Are the Hydrogen atoms balanced? 7. How many Oxygen atoms are on the left side? How many are on the right side? Are the Oxygen atoms balanced? 8. Use this information to balance the equation. 9. Propane burns with oxygen to form water and carbon dioxide also. Write the skeleton equation below. 10. Follow the steps to balance the skeleton equation for the combustion of propane. a. Make sure the number of oxygen atoms is even on both sides. b. Balance the hydrogen atoms c. Balance the carbon atoms d. Balance the oxygen atoms e. Write the complete equation below. 11. Use the clay models to demonstrate the complete combustion of propane. Make more molecules if necessary! Draw models in the space below showing all of the molecules you made and formed in the combustion of propane. 12. Ethanol is also combusted to propel vehicles. Write the equation for combustion of ethanol and balance it! (Hint: It requires oxygen as a reactant and forms carbon dioxide and water as products) Protocol: Ethanol from Corn Part I: Background: Corn kernels consist of four main parts: the pericarp (the hull or outer covering), the germ (the part that sprouts), and the endosperm (the starch inside that expands), and the tip cap (where the kernel’s attached to the cob). The starch is the “food” for the corn and provides energy for its growth. Starch can be separated from other kernel components through a method called wet-milling. It can then be dried and used in a number of practical ways Materials: Dried corn kernels Exacto knife Magnifying glass Bag of frozen corn Bowl Slotted spoon Potato masher Water Cheesecloth Iodine Set-Up 1. Divide corn kernels (one per student) in half vertically with an Exacto knife and keep moist 2. Gather frozen corn, a bowl, and a potato masher Procedure: 1. Obtain a magnifying glass and a large kernel of corn that has been split in half 2. Draw a picture of the vertical cross-section of the kernel in the space below and label the parts Homemade Cornstarch 3. Thaw a package of frozen corn and place in a bowl 4. Crunch up the corn with a potato masher, cover with water. 5. Let stand about 24 hours 6. Remove the corn from the bowl with a slotted spoon 7. Allow the water to stand another 15 minutes 8. Very slowly, gently pour the corny water through a piece of cheesecloth. The starch will get trapped in the cloth. 9. On a small portion of the cheesecloth place a drop of iodine. 10. Record your observations 11. Allow the remainder of the cheesecloth to dry overnight 12. In the morning feel and test the powder remaining on the cheesecloth Part II: Background: Starch in corn must be broken down into simple sugars (like glucose) before fermentation can occur. In earlier times this was done by chewing the corn. This allowed the salivary enzymes to naturally break down the starch. That step is achieved today by cooking the corn and adding enzymes (amylase) to break it down. They function as catalysts and help speed up the chemical changes. Students will prepare and use the enzymes from new sprouts of corn kernels and compare the effect of these enzymes and saliva. The sprouting process in a seed produce enzymes that will convert starch to sugar. Preparation of Enzymes: About two weeks prior to the lab make a malt in which corn is sprouted to a length of about one inch. 1. Soak corn seeds in a pail of warm water for 24 hours. 2. Drain, add more warm water, and drain again after 15 minutes. 3. Spread the soaked seeds on a wet towel, cover with another wet towel and a plastic sheet (keeps towels moist). 4. When sprouts reach a length of one inch, remove sprout and kernel from towels and let dry. 5. When malt is thoroughly dry, it can be ground for use in the mash. Materials for Fermentation: Thermometer Stirring rod Distilled water (preheated and room temp) Balance Beakers Erlenmeyer flasks Lab towels pH paper Sulfuric acid Sugar Bunsen burner or hot plate Safety glasses Corn (shelled, meal, grits, or flour) Grinding apparatus (rocks and boards/mortar and pestle) Materials for Distillation Cloth Beakers Burner set up (Bunsen or alcohol burner, ring stands, wire screen, iron rings) Graduated cylinder Empty soda can 4 to 8 oz. clear glass jar with narrow opening at top larger jar or other container to hold above 4in x 12 in piece of aluminum foil Lab grade ethanol Safety glasses Fermentation Procedure: 1. In a beaker, mix 50 g of corn with 300 ml of preheated distilled water. (Corn mash can be obtained from feed mills and stores – it has consistency of coarse sand) 2. Add 1 or 2 drops of sulfuric acid to adjust pH to 5 3. Bring the mixture to a boil, stirring constantly, for 15 minutes While the mash is boiling prepare the malt 4. In an Erlenmeyer flask, mix 12 g of the prepared ground malt (made from the sprouting) with 100 ml of distilled water. 5. Prepare the yeast: In a test tube, mix 0.5 g of yeast with 20 ml of warm (29C/85F) water. Add a pinch of sugar and watch for bubbling to show yeast is active. Set aside. 6. When mash has boiled 15 minutes, remove it from the heat and cool it for 5 minutes, stirring constantly. 7. Set beaker in warm, cool, then ice water to speed up cooling process. Stir occasionally and check temperature. 8. Add malt solution when mash has cooled to 63C/145F. These enzymes will help break down the starch polymers into their sugar particles. 9. Allow to cool to 28C/83F, then stir in yeast solution. Yeast is a single-celled fungi that feeds on sugar and causes the fermentation. Since a simple sugar has been obtained, the yeast can now be added. 10. Cover the beaker with a small plastic bag, or transfer the mixture to an Erlenmeyer flask. A pipette rubber hose can be attached to transfer the CO2 to a different container with water to witness the bubble formation. 11. Make observations of the liquid and the gas being formed. 12. Let the mixture stand at room temperature for several days. When the bubbling stops, fermentation has ended. Distillation Procedure 1. Squeeze fermented mash through a cloth into the soda can until it is 1/3 to ½ full. OR Being careful not to disturb the mash, use a pipette to draw off the top clear layer of liquid. 2. Mount the soda can above the burner on a wire screen supported by an iron ring (attached to the ring stand). Mount the second iron ring around and near the top of the can to prevent it from tipping over. 3. Insert the smaller glass jar into the larger one and surround liberally with an Ice-rich slush bath 4. Prepare an air-cooled condenser made of aluminum foil. Do this by wrapping the foil lengthwise around a dowl rod or broom handle, taking care to seal the seam that runs the length of the foil tube by making several folds of foil neatly pressed back on itself. 5. Fit one end of the condenser into the opening at the top of the soda can. Gently bend the other end down and insert it into the small glass graduated cylinder which serves as a receiver flask for the distillation. 6. Heat the soda can and its contents with a steady flame. 7. The liquid should contain about 10% ethanol, so distill into a graduated cylinder the first 10% (~5 ml). 8. Carefully smell the fuel and the lab grade ethanol by wafting and make observations. . BIODIESEL MODEL 1: Internal Combustion, Four-Stroke Gasoline Engine Based on the Model, what are the four strokes of this four-stroke combustion cycle to convert gasoline into motion? During the intake stroke, the engine takes in the two reactants needed for combustion. What does it intake? Based on the Model, what part of the engine is responsible for the ignition of the gasoline? What type of motion is generated from this engine? MODEL 2: Four-Stroke Diesel Engine The diesel engine also uses a four-stroke combustion cycle. What are the four strokes? MODEL 3: Gas Engine versus Diesel Engine Based on the Model, how is the injection and ignition of fuel different in the diesel engine when compared to the gasoline engine? MODEL 4: Diesel Fuel versus Gasoline DIESEL GASOLINE Engine Type Four-stroke internal combustion Four-stroke internal combustion Fuel Injection Direct fuel injection, highcompression, no ignition source Driven by a spark, spark plug needed to ignite gasoline Flash Point > 62 C -43 C Autoignition Temperature 210 C 246 C Chemical Formula C14H30 C9H20 Energy Density in 1 Gallon 155 x 106 Joules (147,000 BTU) 132 x 106 Joules (125,000 BTU) Cost (per Gallon) $3.43 $3.11 Based on the Model how what are the relative flash points and autoignition temperatures for diesel and gasoline? Explain why these properties are important considering the fuel injection for the different engines. What fuel source has more energy? What fuel source do you think gets better mileage? Why? Fuels with more carbon atoms are heavier and less refined. Which fuel do you think requires more refining? Explain your reasoning. According to the Model which fuel is cheaper? Why do you think is the cause of this? Technical Definition from the National Biodiesel Board: A fuel comprised of mono- alkyl esters of long chain fatty acids derived from vegetable oils or animal fats. In the next section, we will take a closer look at the meaning of this definition. MODEL 5: Fat: The Common Thread of Biodiesels A triglyceride is a fat. What atoms are present in fats? Circle the glycerol molecule in the triglyceride. The chains attached to the glycerol on the triglyceride are called fatty acids. Put a rectangle around each of the fatty acids. Why do you think this fat molecule is called a triglyceride? (HINT: What does the prefix “tri” mean?) MODEL 6: Transesterification: Making Biodiesel from Oils Ester functional group How many triglycerides are used as reactants? How many molecules of methanol? How many esters are formed? The ester molecules are what we know as biodiesel. Based on the color scheme in this Model, what 2 molecules rearrange to form biodiesel? Explain in words what is happening in this transesterification reaction. MODEL 7: Basic Technology in Biodiesel Process What is the process of removing glycerin from the triglyceride/vegetable oil molecule called? What happens during the refining process? What can glycerin be used for after it is removed from vegetable oil? What are three benefits of producing biodiesel from used vegetable oil? .. ,, MODEL 8: Microalgal Oil for Biodiesel What is a byproduct of power to grid? What are the necessary ingredients used in the production of algal biomass? How is CO2 involved in this process? Explain two ways that biomass is used to produce energy in this process. MODEL 9: Process of Algal Biodiesel Production In Step 1, what does algae require to produce oil? In Step 1, how do you produce a greater oil yield? How much oil is extracted from the screw press? After oil is extracted from the screw press, how is it treated before it is ready for use in a diesel engine? How many more gallons per acre can algae produced as compared to soy? Coconut? Palm? Research at WUSTL Watch the following video: http://news.wustl.edu/news/Pages/21543.aspx. How are clean coal research, carbon sequestration and production of algal biodiesel related? Investigating Biodiesel Properties, Production and Efficiency Protocol: Determining Catalyst Needed for Biodiesel Production Purpose: To make a mini batch of biodiesel to determine the amount of catalyst needed for large-scale production Protocol: 1. 2. 3. 4. 5. 6. 7. 8. 9. . . , , Dissolve 0.9 grams KOH into 20 ml of methanol Add 100 ml of vegetable oil to the mixture Mix vigorously for 5-15 minutes Allow to settle for 30 minutes. Did two separate layers occur? If yes, use 0.9 grams of KOH per liter of vegetable oil. If no, go to step 5. Dissolve 1.0 grams of KOH into 20 ml of methanol Add 100 ml of vegetable oil to the mixture Mix vigorously for 5-15 minutes. Allow to settle for 30 minutes. Did two separate layers occur? If yes, use 1.0 grams per liter of vegetable oil. IF no, try again using 1.1 grams of KOH. Continue this process by raising the amount of KOH by 0.1 grams until separation occurs. When separation occurs, you have determined the proper amount of KOH to use per liter of vegetable oil for large-scale production Protocol: Properties of Various Cooking Oils Adapted from Beyond Benign 2010 This lab contains 2 parts: Part 1: Density of various cooking oils Part 2: Freezing point and melting point of various cooking oils Background: Which vegetable oils are the best for use as biodiesel? What property do you think a vegetable oil should have in order to operate properly in a diesel engine? To think about this, we will first take a closer look at vegetable oils that we find in the kitchen. Although these oils are similar to those used in biodiesel, they cannot be used directly as fuel. These oils need to be chemically converted to biodiesel fuel. Objective: Determine the density of various cooking oils Determine the freezing point and melting point of various cooking oils Part 1: Density of various oils Materials: Scale or triple beam balance 50 mL graduated cylinder 4 x various cooking oils (i.e. vegetable, canola, corn, peanut oils) Procedure: 1. Work in pairs. Wear safety goggles, gloves and apron. 2. Weigh an empty 50 mL graduated cylinder. Record the mass in grams (g). 3. Pour 20 mL of vegetable oil into the 50 mL graduated cylinder. Record the exact volume of the vegetable oil in milliliters (mL). 4. Weigh the graduated cylinder and vegetable oil on a scale. Record the mass in grams (g). 5. Repeat steps 3-5 for all of the various oils. Use clean glassware for each oil. 6. Calculate the density of each oil by filling in the data sheet. Data for part 1 (density of various cooking oils): Vegetable oil 1. Mass of an empty 50 mL graduated cylinder (in g) _____________________________ 2. Mass of a 50 mL graduated cylinder + 20 mL vegetable oil (in g)___________________ 3. Mass of 20 mL of vegetable oil (in g) [line 2 – line 1] _________________________ 4. Volume of 20 mL vegetable oil as determined from the graduated cylinder (mL) _________________________ 5. Density (d) of vegetable oil (g/mL) [line 3 ÷ line 4] (show calculations including units) Canola oil 1. Mass of an empty 50 mL graduated cylinder (in g)_______________________________ 2. Mass of a 50 mL graduated cylinder + 20 mL canola oil (in g)_____________________ 3. Mass of 20 mL of canola oil (in g) [line 2 – line 1] ____________________________ 4. Volume of 20 mL canola oil as determined from the graduated cylinder (in mL) ___________________________________ 5. Density (d) of the canola oil (g/mL) [line 3 ÷ line 4] (show calculations including units) Corn oil 1. Mass of an empty 50 mL graduated cylinder (in g) _________________________ 2. Mass of a 50 mL graduated cylinder + 20 mL corn oil (in g)______________________ 3. Mass of 20 mL of corn oil (in g) [line 2 – line 1]_______________________________ 4. Volume of 20 mL corn oil as determined from the graduated cylinder (in mL) ___________________________________ 5. Density (d) of the corn oil (g/mL) [line 3 ÷ line 4] (show calculations including units) Peanut oil 1. Mass of an empty 50 mL graduated cylinder (in g) ______________________________ 2. Mass of a 50 mL graduated cylinder + 20 mL peanut oil (in g)_____________________ 3. Mass of 20 mL of peanut oil (in g) [line 2 – line 1]_____________________________ 4. Volume of 20 mL peanut oil as determined from the graduated cylinder (in mL) ___________________________________ 5. Density (d) of the peanut oil (g/mL) [line 3 ÷ line 4 ] (show calculations including units) Part 2: Freezing point and melting point of various cooking oils Materials: 4 x various types of oils (i.e. vegetable, canola, corn, peanut oils) 4 x graduated plastic transfer pipettes 2 x thermometers (wide-range) 1 x 500 mL beaker 1 x glass stirring rod 4 x test tubes (12 x 75 mm test tubes are a good size) 1 test tube rack Rock salt Ice Dry ice (optional) Water Procedure: 1. Label a test tube with the name of the first oil. 2. Using the graduated plastic transfer pipette, transfer 2 mL of this oil into the correspondingly labeled test tube. 3. Place a thermometer into the test tube. 4. Set the test tube in the test tube rack. 5. Add rock salt, ice and water to a 50 mL beaker. Stir the water with a glass stirring rod to dissolve the salt. 6. Optional step: add dry ice instead of ice to the salt water mix after salt has fully dissolved. 7. After the salt has dissolved (or after 5 minutes if dry ice was added in step 5), record the temperature of the water in the beaker in degrees Celsius (°C). 8. Transfer the test tube from the test tube rack into the beaker, making sure not to get any water into the test tube. 9. Observe the oil in the test tube. Record the temperature on the thermometer inside the test tube when the oil solidifies. This is the freezing temperature of the oil. 10. Remove the test tube from the beaker and place it in the test tube rack. 11. Observe the oil in the test tube and record the temperature at which it begins to liquify. This is the melting point of the oil. 12. Repeat steps 2-11 for each oil, using a new pipette and test tube for each oil. 13. Fill in the data table on the next page. Data for part 2 (freezing point and melting point of various cooking oils): Oil name Freezing point (°C) Temperature of water, rock salt and ice: Melting point (°C) ˚C [If dry ice was used instead of ice, Temperature of water, rock salt and dry ice: ] ˚C Questions: 1. Which oil has the lowest freezing point? 2. Is the freezing point of the oils the same as the melting point of the oils? 3. What is the definition of freezing point? Of melting point? 4. What happens during the freezing/melting process in terms of molecular dynamics? 5. Besides density, freezing points and melting points, what other properties might help you differentiate the oils? 6. If you are investigating the use of these oils for biodiesel engine, which oil will you choose? Why? 7. What benefit do you think biodiesel has over the traditional diesel gas? 8. What are some examples of chemical change? How are they different from a physical change? Further thinking: 1. What is the freezing point of water? 2. What was the temperature of the water with rock salt and ice in it? 3. If dry ice was used, what was the temperature of the water with rock salt and dry ice in it? 4. How low can the temperature of water and rock salt go before ice forms (water solidifies)? 5. Explain why the freezing point of water is lowered with the addition of rock salt. Protocol: Synthesis of biodiesel Adapted from Beyond Benign 2010 This investigation contains 2 parts: Part 1: Synthesis of biodiesel Part 2: Separation and purification of biodiesel Background: Biodiesel is a fuel made from vegetable oil through a reaction called transesterification. Transesterification is a reaction between an ester and an alcohol in The main component of vegetable oil is a molecule called triglyceride (also known as triacylglycerol). Triglyceride is composed of a glycerol group linked by an ester bond to 3 fatty acid molecules. PreLab Questions: 1. What is the name of the reaction used to make biodiesel? 2. What is a fatty acid? Draw the structure. 3. What molecule in vegetable oil takes place in the reaction to form biodiesel? Draw the structure of this molecule. 4. What happens when the alcohol is added in the transesterification reaction? Part 1: Synthesis of biodiesel Materials: 20 mL of ethanol (CH3CH2OH) 0.35 g sodium hydroxide (NaOH) 20 mL of vegetable oil 1 x 125 mL Erlenmeyer flask 1 x magnetic stir bar 1 x stir/hot combination plate 1 x balance or scale 1 x weigh paper or weigh boat 1 x spatula or scoopula 1 x 50 mL graduated cylinder 1 x 25 x150 mm test tubes (or multiple smaller tubes) 1 x test tube rack 1 x thermometer capable of measuring 40˚C Procedure: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. You will work in pairs. Wear safety goggles, gloves and apron. Measure 20 mL ethanol in the 50 mL graduated cylinder. Transfer the ethanol into the 125 mL Erlenmeyer flask. Add a magnetic stir bar into the flask. Place the flask on a stir/hot plate and turn on the stir function on the stir/hot plate. Stir the ethanol at a medium speed. Using weigh paper (or a weigh boat) and a spatula (or a scoopula), measure 0.35 g of NaOH on a balance. Transfer the NaOH into the flask. Allow the solution to stir until all of the NaOH has dissolved. Sodium ethoxide has formed inside the flask. Measure 20 mL of vegetable oil using the graduated cylinder. Transfer the vegetable oil into the flask. Turn on the heat function of the stir/hot plate and allow the vegetable oil to warm to 40ºC. Heat and stir the mixture at 40˚C for 30 minutes. Turn off the stir/hot plate and remove the flask from the top of it. Pour the mixture in the flask into one 25 x 150 mm test tube (or split the mixture into multiple smaller tubes) and place the test tube(s) in the test tube rack. Allow the mixture to sit in the test tube rack overnight to separate into 2 layers: biodiesel and glycerol. Part 2: Separation and purification of biodiesel Note: After allowing the mixture from part 1 to sit overnight, the test tubes will show 2 layers of materials. The top layer is biodiesel and the bottom layer is glycerol. In this part, the biodiesel will be separated from glycerol and neutralized using a weak acid, 0.1 M acetic acid. Acetic acid is a weak organic acid that you may have already had contact with at home. Vinegar (commonly used for cooking) is 5% acetic acid. Although the acetic acid is a weak acid, do not allow direct contact with skin nor ingest the 0.1 M acetic acid. Materials: Biodiesel mixture synthesized in part 1 of lesson 1 1 x 25 mL graduated cylinder 1 x 50 mL beaker 2 x plastic transfer pipettes 0.1 M Acetic acid Drying agent (i.e. calcium chloride) pH indicator strips or pH meter Procedure: 1. Pipette the top biodiesel layer from the mixture and transfer it into the graduated cylinder. Record the volume of the biodiesel in milliliters (mL). 2. Transfer the biodiesel into the beaker. 3. Using a pH strip or a pH meter, measure the pH of the biodiesel. 4. Neutralize the biodiesel. a. Add 20 drops of 0.1 M acetic acid into the beaker, or until a neutral pH is obtained. KEEP TRACK OF HOW MANY DROPS WERE ADDED. b. Mix the solution thoroughly after each addition of the 0.1 M acetic acid. c. Use pH indicator strips (or a pH meter) to determine the pH of the biodiesel. d. Record the final pH of the biodiesel. 5. Add a few pellets of a drying agent into the beaker. Mix the contents. 6. Label the biodiesel test tubes with your initials, the date and “biodiesel” 7. Store the biodiesel in a dry location at room temperature. Data: 1. Volume of biodiesel in step 1: 2. Number of drops of 0.1 M acetic acid added into order to obtain a neutral pH: __________mL __________drops 3. Assuming 20 drops = 1 mL, how many mL of 0.1 M acetic acid were added to the biodiesel? __________mL 4. What was the starting pH of the biodiesel (from step 3)? _________˚C 5. What is the final pH of the biodiesel (from step 4)? _________˚C Questions: 1. If methanol (CH3OH) was used instead of ethanol (CH3CH2OH), sodium ethoxide (CH3CH2O-Na+) would not be formed. What WOULD be formed instead? Draw the structure of this molecule. 2. Why is 0.1 M acetic acid used to neutralize the biodiesel mix? 3. How many drops or mLs of 0.1 M acetic acid were required to neutralize your biodiesel mix? Protocol: Analysis of biodiesel Adapted from Beyond Benign 2010 This investigation contains 2 parts: Part 1: Density and freezing/melting point of biodiesel Part 2: Heat of combustion of biodiesel Part 1: Density and freezing/melting point of biodiesel Materials: Biodiesel 1 x 50 mL graduated cylinder 1 x 100 mL beaker 1 x triple beam balance or scale Ice and rock salt OR dry ice Water Test tubes Thermometer Calculator Procedure: 1. 2. 3. 4. You will work in pairs Wear safety goggles, gloves and apron Weigh the empty 50 mL graduated cylinder. Record the mass in grams (g). Transfer 20 mL of biodiesel into the 50 mL graduated cylinder. Record the volume of the biodiesel in milliliters (mL). 5. Weigh the graduated cylinder and biodiesel on a scale. Record the mass in grams (g). 6. Determine the mass of the biodiesel 7. Calculate the density of the biodiesel 8. Transfer the biodiesel evenly into 3 test tubes 9. Set up an ice bath by dissolving some rock salt in water and ice in a 100 mL beaker. 10. Place the test tubes of biodiesel into the beaker, making sure not to get any water into the test tubes 11. Place a thermometer into each test tube 12. At every 1 minute interval, record the temperature of the biodiesel and the physical state of the biodiesel (solid, liquid, etc.) 13. If the biodiesel solidifies (freezes), record the temperature on the thermometer 14. If the biodiesel does not freeze and the temperature inside the test tubes is below 20˚C, the monitoring can stop 15. Remove the biodiesel test tubes from the beaker and allow it to sit at room temperature 16. Monitor the temperature at which the biodiesel melts (the solid or gelled biodiesel is back to liquid state, and seems to clarify in appearance) Data for part 1 (Density and freezing/melting point of biodiesel): Density of biodiesel 1. Mass of an empty 50 mL graduated cylinder (in g)______________________________ 2. Volume of biodiesel measured in graduated cylinder (in mL)______________________ 3. Mass of biodiesel and graduated cylinder (in g) ______________________________ 4. Mass of biodiesel (in g) line 3 – line 1 ___________________________________ 5. Density of biodiesel (in g/mL) line 4/line 2 Questions: 1. Given the following information: glycerol’s density is 1.26 g/mL and your biodiesel density from the above section in g/mL, would you be able to identify which layer was which when the biodiesel mix separated? How so? 2. What were some possible mistakes that you can make? Freezing point of biodiesel Time (in minutes) Temperature of biodiesel (˚C) At what temperature did the biodiesel freeze? State of biodiesel (solid or liquid) ____________˚C Melting point of biodiesel Time (in minutes) Temperature of biodiesel (˚C) At what temperature did the biodiesel melt? State of biodiesel (solid or liquid) __________˚C Part 2: Heat of combustion of biodiesel Materials: Wad of steel wool (with the diameter of a quarter) Metallic sample cup Plastic transfer pipettes Biodiesel Triple beam balance or scale Empty, dry soft drink can Glass stirring rod Ring stand with ring holder Match sticks Deionized water 100 mL graduated cylinder 200 mL beaker Thermometer Hotplate Tongs Calculator Procedure: 1. Clamp the ring holder onto the ring stand. 2. Obtain the dry empty soft drink can and adjust the flip top so that the flip top is vertical and perpendicular to the can opening. 3. Take the glass stirring rod and stick it through the hole in the flip top of the can. Slide the can so that it hangs from the middle of the glass stirring rod. 4. Place the glass stirring rod over the ring holder on the ring stand. The soft drink can should hang from the rod, and be below the opening of the ring holder. 5. Measure 100 mL of deionized water using a 100 mL graduated cylinder 6. Pour the deionized water into the soda can 7. Measure the initial temperature of the water in the can using the thermometer 8. Place the wad of steel wool in the metal sample cup. 9. Weigh the metal sample cup with the wool in it using the triple beam balance. Record the mass of the metal sample cup. 10. Pipette 5 mL of biodiesel into the metal sample cup. 11. Measure the metal sample cup with the biodiesel in it. Record the mass of both and determine the mass of the biodiesel. 12. Place the metal sample cup with the biodiesel on top of a hot plate. Turn on the hot plate. 13. Allow the metal cup to get hot, then ignite the biodiesel will inside by using a match. Exercise extreme caution. 14. Using tongs, transfer the metal cup from the hot plate and place it 2 inches below the soft drink can on the ring stand. 15. Allow the heat from the burning biodiesel to warm the water in the soft drink can. If the biodiesel stops burning but there is still biodiesel left in the metal cup, reignite the biodiesel using a match. 16. Once the biodiesel has completely burned so that no more is left, record the final temperature of the water in the soft drink can. 17. Allow the metal cup to cool to room temperature, then weigh it on the scale to determine the mass of any residual biodiesel. 18. Calculate the heat of combustion of the biodiesel per gram of biodiesel. 19. Compare the biodiesel’s heat of combustion with that of commercial diesel fuel. Data for part 2 (heat of combustion of biodiesel): Heat of combustion 1. Mass of an empty metal sample cup (in g) ________________________________ 2. Mass of a metal sample cup with biodiesel prior to combustion (in g)_______________ 3. Mass of biodiesel prior to combustion (in g) line 2 – line 1_______________________ 4. Mass of metal cup after biodiesel combustion (in g) ___________________________ 5. Mass change of metal cup (in g) line 3 – line 4 _______________________________ 6. Amount of water added into empty soft drink can (in mL) ________________________ 7. Density (d) of water (g/mL) 8. Mass of water in soft drink can (in g) _____________________________ 9. Initial temperature of water (in ˚C) ______________________ 10. Final temperature of water (in ˚C) _______________________ 11. Temperature change of water (in ˚C) line 10 – line 9 ___________________ 12. Heat of combustion of water (in cal/g) Heat of combustion equation: Q=cmxT Where Q = heat of combustion (cal/g) c = specific heat (cal/g ˚C) specific heat of water = 1 cal/g ˚C m = mass (g) ΔT = change of temperature change (˚C) 13. Heat of combustion of biodiesel (in cal/g) line 12 ÷ line 5 14. Is the heat of combustion of the biodiesel you synthesized similar to the heat of combustion of the fossil fuel diesel? Heat of combustion of diesel = 10,700 cal/g Bioproducts: What can we make out of organics? WHY? A new discipline of engineering is emerging based on green chemistry. Plant scientists and other biologists have begun partner with academic colleagues, industry and government agencies to design, develop and implement sustainable biosolutions. These bioproducts have the potential to replace petroleum-based products, as well as be recycled, renewed and re-used for multiple applications. Many biobased products are currently being sold and more being developed. It is necessary to understand the scope of this part of biomass energy because it is such an emerging industry in the United States and internationally. MODEL 1: Uses of Oil After crude oil is drilled, what are the 9 it can be used? Where is most oil used? How much of the total crude oil is used to make plastics? MODEL 2: Renewable Bioproducts Based on the Model, what are the four major precursors to bioproducts? What processes are used to create bioproducts? List five examples of bioproducts. Research one of these bioproducts. What stage of development is it in? Is it widely available? What research is still underway related to this bioproduct? MODEL 3: Polymerization Based on the Model, what is ethene? Based on the Model, what is polyethene? What is a definition of a monomer? What is a definition of a polymer? What is the name of the plastic that is used for milk bottles? What is the name of the plastic used for food trays, bottled water and shampoo? What monomer is used to create PVC? Investigating Biodegradables Protocol: Making and Testing Corn Plastic Purpose: To explore the properties of biodegradable plastic made from corn products Materials: Cornstarch Sandwich size zipping bags Corn oil Medicine dropper Measuring spoons Water Food coloring Microwave Procedure: 1. Place a tablespoon of cornstarch in a zipping bag 2. Add two drops of corn oil to the cornstarch 3. Add 1 ½ tablespoons of water to the oil and cornstarch 4. Stir the mixture 5. Add two drops of food coloring to the mixture and stir well 6. Make observations 7. Microwave your plastic for 20-25 seconds on high 8. Make observations 9. Form your plastic into a ball. Make observations. Make Corn Putty Play with it like clay, then watch it become liquid again. Materials: 1 cup cornstarch 1/4 cup + 1 tablespoon water food coloring 1. Blend mixture with fork. It should flow when the bowl is tipped but feel solid when you touch it. 2. If it’s too thick, add a little water. If it’s too runny add a little cornstarch. Protocol: Worm Bin Composting From Vernier Our newest environmental project at Vernier is composting with a worm bin. Our worm bin is a large, locally made, unfinished cedar chest with about 60 cubic feet of capacity. The bin is located in a shady spot on the side of our building, and contains a colony of red wiggler worms. We collect food scraps and coffee grounds, along with coffee filters, in a compost pail in our kitchen. Volunteers, called the "worm wranglers," empty the pail into the worm bin several times a day. We also add paper towels and grass clippings to our composting worm bin. The worms turn this portion of our garbage into nutrient-rich compost that we can use on plants around our building. Keeping a colony of red wiggler worms happily composting is not as easy as you might think. If the colony of worms gets too hot or too dry, the worms can die. For this reason, we monitor temperature and carbon dioxide production from our worm bin using a LabQuest, a Stainless Steel Temperature Probe, and a CO2 Gas Sensor. The graph below shows data taken from our worm bin over a period of 50 hours. A 6 V, 12 Ah motorcycle battery served as the power supply for the LabQuest. We monitored the temperature inside the compost heap and CO2 levels in the air in the bin during this period. You can clearly see in the graph that as temperature rises and falls, so does the level of CO2 in the bin. Daily fluctuations in worm bin temperature (red) and carbon dioxide levels (blue) If you have any questions about how to adapt your LabQuest to record continuously for more than eight hours, contact John Melville. Culminating Project Why? The goal of the culminating project is to assess if students know, what they know and whether they understand the content, concepts and processes discussed in this unit. In addition, the assessment is designed to see how well they know and understand solar energy conversion and uncover what they still do not know or understand. A performance task is a complex scenario that provides students an opportunity to demonstrate what they know and are able to do concerning this concept. We ask students to apply all that they have learned in this unit to an authentic real life situation. Using the GRASP Framework for Authentic Assessment of Learning “To begin with the end in mind means to start with a clear understanding of your destination. It means to know where you’re going so that you better understand where you are now and so that that steps you take are always in the right direction.” –Stephen Covey G Goal: Provide a statement of the task; establish the goal, problem, challenge or obstacle in the task. R Role: Define the role and/or job of the students in the task. A Audience: Identify the target audience within the context of the scenario (e.g., clients, committee, community members) S Situation: Set the context of the scenario; explain the situation P Products or Performances: Clarify what the students will create and why they will create it S Standards/Criteria (to judge product or performance): Provide students with a clear picture of success; issue rubrics or develop them with the students Biomass Energy Expert Task: Driving Questions: What are the four major applications of biomass energy? How can we minimize CO2 production? How can we maximize the amount of biomass energy? Goal Apply knowledge of biomass energy to develop a plan for using biomass energy in your assigned region Role Biomass Specialist Audience Regional Business Council of your assigned region Situation The Regional Business Council in your region is looking to determine ways of using biomass to both decrease CO2 and increase energy from biomass sources. You are being asked to determine how to utilize biomass energy in order to decrease the region’s carbon footprint and provide a source of renewable source to the grid. You must test your model to determine its success. Performance/Product Scientific Poster and Presentation of model. The Poster will describe the scientific process you used for making your decision. You must present your proposal and the model to the Regional Business Council for judging. Standards/Criteria See holistic scoring guide below for overall project Instructions for the Student: Solar energy is absorbed by plants in a process called photosynthesis. The chemical energy in plants gets passed on to animals and people that eat them. Biomass is a renewable energy source because we can always grow more trees and crops, and waste will always exist. If we design and create a means for converting biomass to other forms of energy then we can reduce the emissions of CO2 and add renewable energy to the energy profile. Your group has been provided a region. Your task is to determine (1) the variety of biomass technology applications available and the relative efficiencies (2) reduce the carbon footprint of the region (3) decide what biomass technologies your region should utilize and (4) communicate how research on your specific region has informed your decisions. Dimensions of the task: Understandings: Solar energy is the primary source of energy for all biomass Biomass energy is a renewable energy source which can be transformed to heat energy, chemical energy, mechanical energy and electrical energy Utilization of biomass energy can reduce the carbon footprint of a region Knowledge: Skills: Carbon cycle Apply knowledge of science and technology to create a model to decrease CO2 and increase utilization of biomass energy Greenhouse gases Biochar Gasification Ethanol Biodiesel Transesterification Refiining Four-stroke engine Polymerization Compost Conduct the project, specifying the problem, research, design, experimental process, analysis of data, results and solutions Holistic Scoring Guide Score Description 5 Demonstrates complete understanding of the problem. All requirements of task are included in response. 4 Demonstrates considerable understanding of the problem. All requirements of task are included. 3 Demonstrates partial understanding of the problem. Most requirements of task are included. 2 Demonstrates little understanding of the problem. Many requirements of task are missing. 1 Demonstrates no understanding of the problem 0 No response/task not attempted Student Names: Science Poster Rubric CATEGORY Expert Post Doc Graduate Student Undergraduate Graphics Clarity Graphics are all in focus and the content easily viewed and identified from 6 ft. away. Most graphics are in focus and the content easily viewed and identified from 6 ft. away. Most graphics are in focus and the content is easily viewed and identified from 4 ft. away. Many graphics are not clear or are too small. Graphics Relevance All graphics are related to the topic and make it easier to understand. All borrowed graphics have a source citation. All graphics are related to the topic and most make it easier to understand. All borrowed graphics have a source citation. All graphics relate to the topic. Most borrowed graphics have a source citation. Graphics do not relate to the topic OR several borrowed graphics do not have a source citation. Labels All items of importance on the poster are clearly labeled with labels that can be read from at least 3 ft. away. Almost all items of importance on the poster are clearly labeled with labels that can be read from at least 3 ft. away. Several items of importance on the poster are clearly labeled with labels that can be read from at least 3 ft. away. Labels are too small to view OR no important items were labeled. Content Accuracy At least 7 accurate facts are displayed on the poster. 5-6 accurate facts are displayed on the poster. 3-4 accurate facts are displayed on the poster. Less than 3 accurate facts are displayed on the poster. Knowledge Gained Student can accurately answer all questions related to facts in the poster and processes used to create the poster. Student can accurately answer most questions related to facts in the poster and processes used to create the poster. Student can accurately answer about 75% of questions related to facts in the poster and processes used to create the poster. Student appears to have insufficient knowledge about the facts or processes used in the poster. Attractiveness The poster is exceptionally attractive in terms of design, layout, and neatness. The poster is attractive in The poster is terms of design, layout acceptably attractive and neatness. though it may be a bit messy. Grammar/ Spelling There are 1-3 mistakes on the poster. There are no mistakes on the poster. SCORE The poster is distractingly messy or very poorly designed. It is not attractive. There are 4-6 mistakes There are more than on the poster. 6 mistakes on the poster. Total 35 Biomass Resources Biofuels http://www.habmigern2003.info/biogas/biofuels.html Biofuels, Journey to Forever http://journeytoforever.org/biofuel.html Types of Biofuels http://biofuel.org.uk/types-of-biofuel.html Algae Biofuels http://www.exxonmobil.com/Corporate/energy_climate_con_vehicle_algae.aspx Popular Science Articles on Algae Biofuels http://www.popsci.com/technology/article/2010-01/us-government-throws-78-million-algaebiofuels-research How Biodiesel Works? http://auto.howstuffworks.com/fuel-efficiency/alternative-fuels/biodiesel.htm National Renewable Energy Laboratory, Innovation for Our Energy Future http://www.nrel.gov/learning/re_biomass.html Renewable Energy World http://www.renewableenergyworld.com/rea/news/article/2007/10/new-refinery-to-fix-keyflaws-in-biodiesel-production-50225 U.S. Department of Energy http://www1.eere.energy.gov/biomass/