the manchester materials - School of Materials Intranet

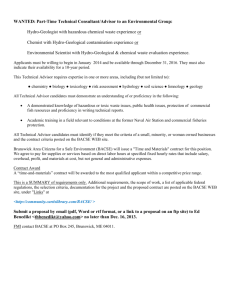

advertisement