Abstract Example 3

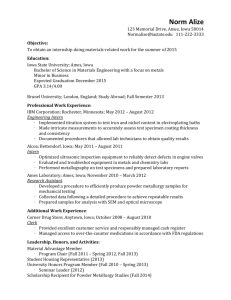

advertisement

Automated Flaw Detection for NDE Images Ye Tian, Amgen Inc., Thousand Oaks, CA 91320; Ranjan Maitra, Department of Statistics and Statistical Laboratory, Iowa State University, Ames, IA 50011; William Q. Meeker, Department of Statistics and the Center for NDE, Iowa State University, Ames, IA 50011; Stephen D. Holland, Department of Aerospace Engineering and Center for NDE, Iowa State University, Ames, IA 50010 Many modern NDE systems generate image data. In some applications an experienced inspector performs the tedious task of visually inspecting every image to provide accurate conclusions about the existence of flaws. This labor-intensive approach can cause misses due to operator error. Automated methods can eliminate human-factors variability and improve throughput. Simple methods based on peak amplitude in an image are sometimes employed and a trained-operator-controlled refinement that uses a dynamic threshold based on signal-to-noise ratio (SNR) has also been implemented. We develop an automated and optimized detection procedure that mimics the operations of a trained operator. The primary goal of our methodology is to reduce the number of images requiring expert visual evaluation by filtering out images that have strong evidence for the existence or absence of a flaw. We use an appropriate model for the observed values of the SNR-detection criterion to estimate POD. Our methodology outperforms current methods in terms of its ability to detect flaws. This work was performed with partial support from the Federal Aviation Administration under contract number DTFACT-09-C-00006 through the Center for Nondestructive Evaluation at Iowa State University. Experimental Studies on NRUS Behavior of Impact Damaged Composite Laminates Hyunjo Jeong, Wonkwang University, Mechanical and Automotive Engineering, Iksan, Jonbuk, Korea; Daniel Barnard, Iowa State University, Center for NDE, Ames, IA 50011 Nonlinear acoustic methods or Nonlinear Elastic Wave Spectroscopy (NEWS) techniques are widely used these days for damage assessment in a large group of materials including metals, rocks and composites. Nonlinear resonant ultrasound spectroscopy (NRUS) is one of those techniques and has proved to be valuable for damage detection because of its high sensitivity. NRUS is a vibration-based technique exploiting the nonlinear resonance behavior of damaged materials. In NRUS, the resonant frequency of an object is sought as a function the excitation level. As the excitation level increases, the material nonlinearity is manifested by a shift in the resonance frequency. In this work, NRUS experiments were conducted on intact and impactdamaged carbon fiber-epoxy composite laminates. Both fundamental and higher harmonic resonance were measured and analyzed. It was observed that undamaged samples exhibited some baseline nonlinearity. With increase in impact damage, nonlinearity increased beyond the baseline nonlinearity. The hysteretic nonlinear parameter was extracted from the change in resonant frequency with peak strain amplitude. The higher order hysteretic parameters were found to be more sensitive to conventional first order parameters for given damage level. This work was supported by National Research Foundation of Korea (2013R1A2A2A01016042).