Food Safety & Sanitation

advertisement

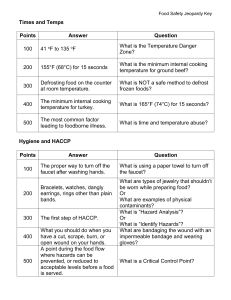

Food Safety and Sanitation The Federal government and each state and local areas have food sanitation regulations that clearly define how to prevent unsanitary and unsafe restaurant conditions. There are 5 federal agencies responsible for food safety. Texas has developed the Texas Food Establishment Rules which are based on the FDA food code. Each food establishment must have at least one person on premises at all times that has been trained in proper food handling- ServSafe Training. The General Manager and the Food and Beverage Manager of a hotel and/or restaurant are both responsible for the safety and sanitation of their operations. Managers are responsible for identifying risks in the day-to-day operation of a foodservice business. They have the ultimate responsibility for serving food that is safe to eat. Periodic inspections are conducted to ensure restaurants are in compliance with those regulations. Permits are issued by local governing authorities to restaurants to ensure food safety. Local health departments are responsible for investigating any reported incidents of foodborne illness. Restaurants can be closed temporarily or shutdown for violations of food safety regulations. Safe food handling practices keeps everyone healthy. Older people, children and pregnant women are more likely to become sick from contaminated food. Some symptoms of foodborne illness care nausea, vomiting, diarrhea, fever, cramps and even death. 1 A contaminant is a substance in food that does not belong in the food. Food Borne illness is a disease that is caused by eating contaminated food. There are three types of contaminants: physical, chemical and biological. Physical contaminants- items that accidentally get into food: hair, fingernails, glass, insects, etc. These might not cause food borne illness but they can cause problems like broken teeth, cuts, etc. Chemical contaminants – a chemical that is toxic not usually found in foods; examples include: cleaning supplies, pesticides, metals in solution. Sometimes cleaning supplies can be mistaken for cooking products or foods; pesticides can remain on foods; metals can leach out of cooking equipment into the foods. Biological contaminants – microscopic living substance that accidentally gets into food. Types of biological contaminants include bacteria, parasites, viruses, molds and fungi. A biological contaminant that causes disease is called a pathogen. Bacteria are the most common cause of foodborne illness. Bacteria reproduce rapidly under ideal conditions, which are often found in food, warm temperatures (between 41 F and 135 F) and a ready food source. The Temperature Danger Zone is room temperature or a temperature between 41 F and 135 F. Foods left at temperatures in this zone for 2 or more hours are 2 potentially dangerous. Bacteria grow best in potentially hazardous foods like raw and undercooked meats, fish, poultry, …casseroles, custards, meat and fish salads, mayonnaise based foods. A Virus is a microorganism that reproduces in the cells of other living things. Foods give viruses a way to get into the human body when a person eats the food that contains the virus. Once the virus is in the body, it can reproduce and make a person sick. To prevent the transmission of viruses use good personal hygiene and proper food handling. Parasites are organisms that must live in another living thing in order to survive. The host can be a person, animal or plant. The parasite gets nourishment from the host. Parasites can range from an amoeba to a tapeworm (up to 30 feet long!) Good personal hygiene and proper food handling again can prevent contamination by parasites. There are three main ways to prevent foodborne illness: personal hygiene, sanitation, and proper handling of food. Personal hygiene – keep your body and clothing clean. Sanitation – Cleaning is the removal of dirt and food, but sanitization is the treatment of a clean surface with 3 chemicals or heat to reduce the number of pathogens to safe levels. Proper handling of food – includes proper storage and cooking Food Sources and Storage Food comes from around the world and from a variety of sources. It is necessary to verify the sources are safe and reliable. Also the shippers must be able to provide verification that they follow standard safety and sanitary practices as well. Foods must be kept separate from supplies and held at the proper temperature during shipping. The food must be packaged for safe shipping and handling. Spoilage is detectable by the senses-sight, tastes, feel however contamination is cannot be detected in this manner. Proper storage areas for foods should be used, never hallways, restrooms, etc. The most important rule is FIFO. Rodents and insects spread disease, contaminate food, and destroy your property. Continuous pest control methods must be employed by good housekeeping and preventing entry of pests. Pesticides should only be used by a licensed pest control operator and as a last resort. 4 Employee Practices 1. stay home when sick 2. fingernails should be kept short (and glued on! LOL) 3. wash hands properly- hot water, soap, single use paper towel to dry 4. wash hands frequently 5. bathe daily 6. wear clean clothing 7. do not wear jewelry 8. keep hair restrained 9. control sweat 10. use gloves when directed 11. use sanitary serving methods Equipment, Utensils and Surfaces All devices used to prepare foods are known as equipment, smaller equipment is known as utensils. Utensils are used for food prep, food service and eating. All equipment must be constructed in such a manner that it is easy to use, clean (Stainless steel), operate, store, take apart and reassemble. Dishwashing involves both cleaning and sanitizing. Dishwashing can be done manually or by machine. Both methods require hot water, soap and clean rinse water. 5 Food Handling Safe handling procedures are necessary to keep food safe and prevent the growth of bacteria in foods. Keep cold foods cold and hot foods hot! When cooling foods to a safe temperature, the goal is to have the foods go through the danger zone as quickly as possible. Reheating, Thawing and Cooling are the 3 food temperature changes that provide the greatest potential for contamination. One of the major dangers when preparing raw foods is crosscontamination or the transfer of microorganisms from one food to another. Examples methods of possible cross contamination are: placing a cooked food on a surface that a raw food has been on, handling both cooked and raw without washing your hands or the equipment used, or dripping juices from raw to cooked foods. The FDA (the federal Food and Drug Administration) has developed temperature recommendations (that are not cooking instructions) for cooking foods to keep foods safe. An accurate thermometer is essential for measuring the temperatures of foods to make sure they have reached the required temps. Holding is keeping potentially hazardous foods out of the temperature danger zone during the periods while the food is waiting to be served to guests. An employee is usually assigned the task of checking and recording the temperatures of foods periodically that are being held. Many companies have 6 developed noncontact, infrared digital thermometers to make temperature checking easier. Sanitation Risk Management (SRM) – focuses on reduction of overall sanitation risks by identifying the risks at each control point in a food service program. In an SRM standards and procedures for each control point are given for each of the four resources. inventory-controls that protect food products, beverages, nonfood items from spoilage, contamination, pilferage, and waste people- employee training in the use of proper sanitation practices equipment- requirement for the proper cleaning and maintenance of all equipment facilities- requirement of a food facility design and layout that has a positive effect on the facility’s ability to provide a safe and sanitary dining environment HACCP (pronounced hass’ ip) is a common SRM (sanitation risk management) plan. It is the 7 step Hazardous Analysis Critical Control Point system. HACCP uses a systematic approach to identify, evaluate, and control food safety hazards. HACCP was developed by a joint venture between Pillsbury and NASA in the 1960s. 7 Critical control points (CCPs) are the activities in the food handling process that must be controlled to ensure food safety. A CCP is when a hazard can be prevented. Each critical control point is given critical limits (CLs). A CL is the action or temperature required for food safety. The written HACCP plan must detail hazards, identify the CCP’s critical limits, specify CCP monitoring and methods of recordkeeping, and outline a strategy for implementing the plan. Following this plan ensures food is safe from its arrival at the restaurant until it is served to the guests. Example of HACCP violations A restaurant purchases pre-prepared potato salad from a vendor. When the potato salad arrives it must be immediately stored at the proper temperature. If it sits out too long waiting to be stored it might pass the CL of time. Once placed in the cooler, the cooler must be at the proper temperature. Cooler temp must be checked every 4 hours and recorded. So a broken, warm cooler could exceed a CL and the salad is contaminated. Once an order for the salad is placed, using an unclean/unsanitized serving utensil puts the salad at risk again. 8