File - Andrew Pany`s E

advertisement

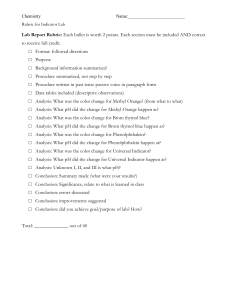

Andrew Pany English 202C The Synthesis of Methyl Orange For Use in the Textile Industry How Dyes Work Since prehistoric times, humans have been dyeing cloth. However, organic chemists have only mastered the coloring process over the past 150 years or so. The organic chemical industry originated in 1856 with William Henry Perkin’s discovery of the first synthetic dye, Perkin’s Mauve. Since that time, chemists have found that fibers usually absorb dyes from an aqueous, water-based, solution. The dye penetrates pores in the fiber and is bound to the fiber in a number of different molecular interactions: Electrostatic Forces – the attraction between positively charged substances, cations, and negatively charged substances, anions Van der Waals Attractions – the attractive forces between especially reactive areas, known as dipoles, of two neutrally charged molecules Hydrogen Bonding – the incredibly strong force between a hydrogen atom attached to a more electronegative (wanting electrons) atom of a molecule Covalent Bonding – a chemical bond that involves the sharing of electron pairs between atoms A suitable dye must be sturdy in the face of lighting, heating, and washing. In other words, the dye must not fade or come off when repeatedly exposed to the elements. The more of the above forces that are contained within the dye-fabric interaction, the stronger the dye will become. The most common dyes seen in industry are azo dyes. Azo dyes are formed by the coupling of amines, nitrogen groups, which are attached to phenols, six membered carbon rings with alternating double bonds, and/or other amines (shown below). This type of dye works very well on wool, silk, and even skin. Methyl orange, a synthetic azo dye, is produced via a two-step process. Figure 1. The structure of methyl orange. Synthesis of Methyl Orange Synthesis Step 1 – The Formation of Diazotized Sulfanilic Acid The first reaction is shown on the next page. Sulfanilic acid sodium salt is added to hydrochloric acid (HCl) and sodium nitrite (NaNO2) to yield diazotized sulfanilic acid, a necessary intermediate in the synthesis of methyl orange (reaction 1). The diazotized sulfanilic acid precipitates out of a solution and appears as a yellow, Andrew Pany English 202C grainy product. Byproducts of this reaction are sodium chloride and water, both of which will remain in solution once the precipitate is filtered. Reaction 1 – The Formation of Diazotized Sulfanilic Acid This diazotization is a fairly straightforward reaction. However, it has two key features that are essential to the synthesis of methyl orange. First, the diazotization swaps the functional group (reactive or external group) on top of the phenol in the salt from an amine (NH2) to a nitrile (N2) in the acid. A nitrile group is much more reactive and, therefore, allows for the simple formation of an azo group, which is seen in methyl orange. Second, the diazotization creates a separation of charge, shown explicitly on the acid. The separation of the positive and negative charges allows the compound to become even more reactive than it would be neutrally, causing the next step of the reaction to proceed very quickly. The increase in reactivity is essential to saving both time and money in the manufacturing process, while simultaneously growing yields. Synthesis Step 2 – The Formation and Purification of Methyl Orange In the second step, the diazotized intermediate is added to N,N-Dimethylanaline in the presence of acetic acid (AcOH), which results in the formation of a stiff, purple paste. Sodium hydroxide (NaOH) is combined with the paste and the new mixture is heated to boiling then cooled, resulting in the formation of the desired methyl orange. However, the crude product must be purified before use. Reaction 2 – Synthesis of Methyl Orange Purifying methyl orange on a large scale, as done in the textile industry, involves dissolving the organic material in a hot solvent, such as boiling water, to give a solution. As the solvent cools, impurities picked up during synthesis are naturally removed from the organic material and a more perfect crystal array begins to form. The solid solute then reemerges in the solution as a single, pure substance with the impurities washed away in the solvent. This purification process is commonly known as recrystallization. The recrystallization practice requires no action, just time. Andrew Pany English 202C A successful synthesis of methyl orange will yield a significant amount of product, mostly due to the reactive nature of the diazotized sulfanilic acid. The refined dye should be a fine powder, appearing red-orange in color as seen below. Figure 2. Purified Methyl Orange. Testing Of Methyl Orange In industry, synthesized dies are tested for their effectiveness on different fabrics. More polar dies, those with more electronegative elements like nitrogen, oxygen, chlorine, and fluorine, will stick to more polar fabrics. On the other hand, less polar dies will stick to less polar fabrics. The old adage “like attracts like” certainly applies here. The reason for this phenomenon of polarity is given by the aforementioned interactions, electrostatic, van der Waals, hydrogen bonding, and covalent bonding. If more polar sites are found on the dye and fabric, then there is a greater chance for these strong intermolecular attractions to occur. To test methyl orange, a dye bath must be prepared by adding water and acid to the die. This solution then heated to a boil with several different pieces of fabric to check the strength of the dye. The sulfonate (SO3) groups on the methyl orange molecule are very polar and thus enable the dye to combine well with polar sites on fibers. For instance, wool and silk have many polar sites and therefore bind strongly to methyl orange, showing plenty of color. Alternatively, nylon, creslan 61, and polyacrylonitrile, have a limited number of polar sites and show little to no color after dyeing. The results of methyl orange’s testing against several fabrics can be seen below. Andrew Pany English 202C Methyl orange, being an industrial dye, will work at any scale as long the bath is proportioned correctly (about 30 liters of liquid to 50 grams of methyl orange). However, when scaling the operation, be wary of the toxicity of methyl orange. Like many synthetic dyes, extreme exposure to methyl orange can cause tumors, heart disease, and lung disease among other ailments. Exercise caution when working with the dye, be sure to wash it off skin and wear a breathing mask to prevent the chalky dust from entering the body. This document does contain some information from: Masters, K.M. Chem 213H Textile Module, Spring 2015. Masters, K.M.; Williamson, K.L. Macroscale and Microscale Organic Experiments: Extraction and Recrystallization, 6th Edition.