Fazal Iqbal

advertisement

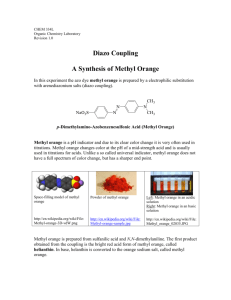

Best conditions to increase the continuous flow of methyl orange also commonly used in the textile industry as a dye product 3). The synthesis of methyl orange is an exothermic 4-step reaction. The two main reactions in the synthesis are: -The nitrosonium ion reacts with the amino of the sulfanilic acid, attaching a second N-atom at the sulfanilic acid to produce a diazonium salt (the process of diazotation): Team member: Fazal Iqbal School: Cygnus Gymnasium Studentnumber:98295 Teamnumber:4 16 April 2012 Summary Methyl orange is an extensively used product in the textile industry as a dye product. It has an intense coloring compound. Chemists use it as an indicator in the titration of weak bases with strong acids. Methyl orange is best produced in a micro reactor where temperature and flow rate can be controlled. In my initial experiment a continuous flow of 0.0028 mol/L was achieved. With regard to its production the following question raises in our minds: What effect does the temperature or flow rate have on the continuous flow of methyl orange? Methyl orange indicator -The diazonium salt is coupled with N,Ndimethylaniline, the coupling takes place in the opposite position from the – N(CH3)2 group: There are certain conditions in the mechanism that are needed for the synthesis of methyl orange such as flow rate and temperature. This raises the following question: what effect does temperature or flow rate have on the increase or decrease of the continuous flow of methyl orange? Therefore I want to examine what the effects will be on the methyl orange production when I vary the temperature or flow rate. My hypothesis on the inquiry question is: Increase in the temperature will increase the continuous flow of methyl orange. Increase in the flow rate will increase the continuous flow of methyl orange. Introduction My theoretical assumption is that: Methyl orange is a pH indicator in the chemistry. It is widely used in titrations because one of the major characteristics of methyl orange is that it changes color clearly and distinctive. It changes from red (at pH 3.1) to orange-yellow (at pH 4.4). However methyl orange also has mutagenic properties, it is Chemical reactions require collisions between reactant molecules or atoms. At higher temperatures collisions will be more violent and the frequency of collisions will increase 2). This means that the chemical reactions will speed up. The higher the flow rate the more the molecules will spread over the time and thereby increasing continuous flow of methyl orange. The product methyl orange is analyzed using an Ocean Optics spectrometer. Results The graph with flow rates of 100 µL/min and 65°C is as follows: Experimental design Methyl orange can be best produced in a micro reactor. This device consists of three inlets and one outlet. Solution A is lead through the first inlet. Solution A consists of 16.7 mmol sulfanilic acid, 16.7 mmol sodium carbonate, 16.7 mmol sodium nitrate, 166.7 mL water and 83.4 mL ethanol. The flow rate at which solution A is lead through inlet 1 is 100 µL/min. Figure: schematic design of micro reactor Solution B is lead through inlet 2 . Solution B contains 3.16 mL N,N-dimethylaniniline, 6.3 mL mL 12 M HCl and 238.7 mL water. This solution is flowed into the reactor with a rate of 100 µL/min. The graph with flow rates of 100 µL/min and 75°C is as follows: Solution C is lead through inlet 3. This solution contains 18.8 mmol NaOH, 62.5 mL water and 187.5 mL ethanol. The flow rate for solution C is set at 100 µL/min. The temperature of the micro reactor is set at 65°C. The same experiment is repeated with the same set up and flow rates but with a different temperature of 75°C in the micro reactor. To research the influence of the flow rates of the three solutions on the flow rate of methyl orange I chose to set the rates at 100 µL/min and 125 µL/min at 75°C. In this experiment the control variables are the flow rate and temperature. The independent variable is the time. The dependent variable is the continuous flow of methyl orange in mol/L. The graph with the different flow rates of 125 µL/min and the same temperature of 75°C is as follows: With same circumstances but increase of the temperature with 10° to 75° a continuous flow of methyl orange was found of 0.0034 mol/L. The concentration that is constantly produced increases with 0.0006 mol/L to 0.0034 mol/L . So at all an increase in the temperature increases the evolvement of the reaction in which methyl orange is produced so that the yield of the methyl orange gets higher. Thereby the first hypothesis could be accepted. As is notable increase in the flow rates of the three solutions with 25 µl/sec and the same temperature retained, decreases the concentration of flow rate of methyl orange that is reached. The main reason could be that the reaction happens at a quicker speed. The yield of methyl orange is reached sooner but the concentration of the methyl orange is a little bit lower. So the second hypothesis wasn’t right at all. We did each of these three experiments two times and in the table you can see all the results: Experim ent 1 Tempe rature 65° 65° Experim ent 2 75° 75° Experim ent 3 75° 75° Flow rate 100 µl/sec 100 µl/sec 100 µl/sec 100 µl/sec 125 µl/sec 125 µl/sec Concentration Methyl Orange 0.0028 mol/L 0.0024 mol/L 0.0034 mol/L 0.0038 mol/L 0.0023 mol/L 0.0019 mol/L Discussion and conclusion From the results shown above there is an important finding observed. First, at 65°C and flow rates of 100 µL/min a continuous flow of methyl orange was reached of 0.0028 mol/L. Evaluation The experimental set up could have been improved by making more measurements. This would have enhanced the reliability and validity of the results. But there was not enough time. In future it will be better to have more time to extend the experiment. This way more measurements can be done. My suggestion for a future experiment will be to have the following inquiry question. What effect does the concentration of solution A, B and C have on the continuous flow rate of methyl orange? Bibliography 1. Kijdna, A.ea. Synthesis of methyl orange in a micro reactor 2. http://www.800mainstreet.com/7/00 07-005-rea-t-cat.html 3. http://antoine.frostburg.edu/chem/se nese/101/acidbase/faq/methylorange.shtml 4. http://en.wikipedia.org/wiki/Methyl_ orange