VBN668 Operate electrical test equipment

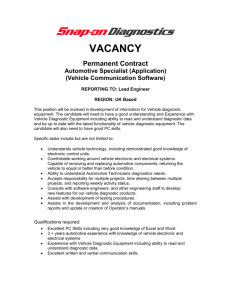

advertisement