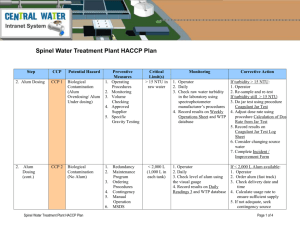

Control measures, monitoring and response – example for microbe

advertisement

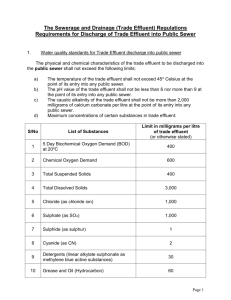

Control measures, monitoring and response – example for microbe hazards Hazard/ System hazardous component event Collection System Treatment System Operational Limit Corrective Action Notify Customer services Compliance with CoP Apply response and/or enforcement actions in accordance with the CoP ADSSC Plant Manager Continuous on line monitoring Shift operator 1.5mg/l ±0.5mg/l Flow rate through system Check flow meters 4 times daily Shift Operator Flow rate between xx and xx L/min Check MLSS, DO and Sludge Age. Carry out microbiological examination of MLSS Assess need to change Sludge age and act accordingly Check turbidity of tertiary treatment feed Site manager Final effluent turbidity Twice per shift times daily Shift operator Final effluent Turbidity must be <5NTU Clean turbidity monitor & check calibration Check operation of sand filters and correct if necessary Take composite sample of final effluent and assess BOD & SS Divert final effluent to head of works for further treatment Site manager O&M Manager & RSB if flow diversion Post filter hypochlorite dose volume Daily Site Operator Dose volume = Influent flow rate x ?? ±10% Site Operator Residual chlorine must be 0.5 to 1.0 ± 0.1mg/l Measures What When Who Management of canteen and laundry dischargers Scheduled inspections Annually Dissolved Oxygen Biological treatment of wastewater Microbiological Pathogens Monitoring Control Tertiary treatment of wastewater by sand filtration Chlorine disinfection of tertiary Spot check of final effluent treated wastewater residual chlorine Disposal System User awareness Information bulletin to AAM Site lab technician Monthly Summary of RW Quality with ADSSCs views on Site Manager use restrictions issued to AAM Clean DO monitor & check calibration Check operation of air blowers & correct if necessary Site manager Take composite sample of secondary treatment effluent and assess BOD & SS Check dosing pump operation and correct if necessary Adjust dosing pump output Check final effluent residual cholrine Site manager Clean chlorine monitor & check calibration Check operation of dosing system and correct if necessary Check quality of tertiary effluent Divert recycled water to head of works for further treatment Alert AAM that residual chlorine out of spec. Site manager AA Municipality O&M Manager & RSB if flow diversion Establish why report not submitted O&M Regional Manager