Spinel Water Treatment Plant HACCP Plan

advertisement

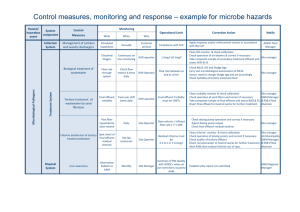

Spinel Water Treatment Plant HACCP Plan Step CCP Potential Hazard 2. Alum Dosing CCP 1 Biological Contamination (Alum Overdosing/ Alum Under dosing) 1. 2. 3. 4. 5. 2. Alum Dosing (cont.) CCP 2 Biological Contamination (No Alum) Spinel Water Treatment Plant HACCP Plan Preventive Measures Operating Procedures Monitoring Volume Checking Approved Supplier Specific Gravity Testing 1. Redundancy 2. Maintenance Program 3. Ordering Procedures 4. Contingency 5. Manual Operation 6. MSDS Critical Limit(s) > 15 NTU in raw water < 2,000 L (1,000 L in each tank) Monitoring Corrective Action 1. Operator 2. Daily 3. Check raw water turbidity in the laboratory using spectrophotometer manufacturer’s procedures 4. Record results on Weekly Operations Sheet and WTP database If turbidity > 15 NTU: 1. Operator 2. Re-sample and re-test If turbidity still > 15 NTU: 3. Do jar test using procedure Coagulant Jar Test 4. Adjust dose rate using procedure Calculation of Dose Rate from Jar Test 5. Record results on Coagulant Jar Test Log Sheet 6. Consider changing source water 7. Complete Incident / Improvement Form 1. Operator 2. Daily 3. Check level of alum using the visual gauge 4. Record results on Daily Readings 3 and WTP database If < 2,000 L Alum available: 1. Operator 2. Order alum (fast track) 3. Check delivery date and time 4. Calculate usage rate to ensure sufficient supply 5. If not adequate, seek contingency source Page 1 of 4 7. SCADA 8. Flowmeter 7. Filtration CCP 3 Biological Contamination (Ineffective Filtration due to: • Algae • Loss of Media) 8. Back Washing CCP 4 Physical /Chemical contamination (Backwash Failure due to: • Clear Water Storage < 9.5 ML) 9. Ammonia dosing CCP 5 Biological contamination (under dosing/no ammonia) Spinel Water Treatment Plant HACCP Plan 1. Daily Backwashing 2. Operation Procedures 3. Visual Inspection Alarms 4. Turbidity Meters 5. Maintenance Schedule 6. Daily Sampling 1. Operating Procedures 2. Manual Operation 1. Operating Procedures 2. Daily Monitoring 3. Volume 6. Record of purchase in purchase order book 7. Record of calculations on Weekly Operations Sheet 8. Complete Incident / Improvement Form > 0.5 NTU for 15 minutes 1. Operator 2. CITEC alarm 3. Recorded on CITEC If turbidity > 0.5 NTU: 1. Operator 2. Initiate backwash 3. Record activity in diary 4. Investigate cause of high turbidity 5. Complete Incident / Improvement Form < 9.5 ML in Clear Water Storage 1. Operator 2. CITEC continually 3. Recorded on CITEC If Clear Water Storage < 9.5 ML: 1. Operator 2. Notify Water Quality Coordinator 3. Investigate why CWS < 9.5 ML 4. Initiate backwash, if necessary 5. Record activity in diary 6. Implement Demand Management Plan, if necessary 7. Complete Incident / Improvement Form If ratio is out of required range: 1. Operator 2. Check plant and equipment 3. Adjust accordingly Chlorine: Ammonia Ratio between 3:1 and 4:1 1. 2. 3. Operator Weekly Drawn down test on Ammonia according to Ammonia Dose Page 2 of 4 Biological contamination (overdosing) 4. 5. 6. 10. pH Correction CCP6 Physical Contamination high pH/turbidity (overdosing) Biological contamination (overdosing) 7. 1. 2. 3. 4. 5. 6. 7. 11. Chlorination CCP 7 Biological Contamination (Under dosing/ No Chlorine) Spinel Water Treatment Plant HACCP Plan Checking Approve supplier Specific Gravity Test Flow Based Dosing On-site spares Operating Procedures Monitoring Redundancy – including an extra lime dispensing system Volume Checking Approved Supplier Maintenance Calibration 1. Operating Procedures 2. Monitoring 3. Volume Checking 4. Approved Supplier 5. Alarms 6. Maintenance 7. Automatic Change-over 8. Manual Dosing Calculation Record results on Weekly Operations sheet and WTP database 4. Draw down test on Ammonia according to Ammonia Dose Calculation 5. Record activity in diary 6. Complete Incident / Improvement Form Operator Daily Check Lime Volume over time according to hydrated Lime Drop Test Take sample from Clear Water Storage and check if pH>8.5 Record results on Weekly Operations Sheet and WTP database If pH >8.5 1. Operator 2. Re-sample and re-test If pH still>8.5: 3.Check plant and equipment 4. Adjust accordingly 5. Record activity in diary 6. Calibrate pH meter if necessary 7. Record on Calibrating Merck WTW pH Meter 8. Check total chlorine using spectrophotometer manufacturer’s procedures 9. Record results on Weekly Operations Sheet and WTP database 10. Complete Incident / Improvement Form 1. Operator 2. Daily 3. Take sample from Clear Water Storage and check Chlorine residual according to spectrophotometer manufacturer’s procedures 4. Record results on Weekly Operations Sheet and WTP database. 5. SCADA Alarm at 1.7 mg/L Total Chlorine If Chlorine Residual < 1.5 mg/L: 1. Operator 2. Re-sample and re-test If Chlorine Residual still < 1.5 mg/L: 3. Check chemicals and plant and equipment 4. Repair and adjust accordingly 5. Initiate manual dosing if necessary 4. > 8.5pH 1. 2. 3. 4. 5. < 1.5 mg/L Total Chlorine Page 3 of 4 6. Record activity in diary 7. Complete Incident / Improvement Form Spinel Water Treatment Plant HACCP Plan Page 4 of 4