Supplementary Data The water footprint of biofilm cultivation of

advertisement

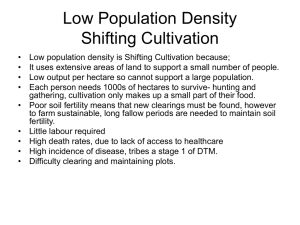

Supplementary Data The water footprint of biofilm cultivation of Haematococcus pluvialis is greatly decreased by using sealed narrow chambers combined with slow aeration rate Shuchao Yin1, 2, Junfeng Wang1, *, Lin Chen1, Tianzhong Liu1, * 1 Key Laboratory of Biofuels, Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences, Qingdao, Shandong, 266101, P. R. China 2 University of Chinese Academy of Sciences, Beijing, 100049, P.R. China *Corresponding author. Tel: +86 532 8066 2735; fax: +86 532 8066 2735. E-mail addresses: Shuchao Yin yinsc@qibebt.ac.cn Junfeng Wang wangjf@qibebt.ac.cn Lin Chen chenlin@qibebt.ac.cn Tianzhong Liu liutz@qibebt.ac.cn Material and methods Before determining the optimized aeration speed, we must assure there is enough carbon to be injected into the chamber even with the lowest aeration speed. So the maximum carbon that deposited inside the biofilm during 7 days cultivation was firstly measured. The final biomass of 1.5% CO2 treatment (fig. 4) was selected to analysis the carbon sedimentation because the biomass and astaxanthin concentration of this treatment were highest among the different treatments (fig.3; fig.4). In Haematococcus, most of the astaxanthin molecules were finally deposited in lipid body in ester style. Both of the triacylglycerol (main component in lipid body) and astaxanthin could be considered as carbon sink inside the cell. The final algal cells were harvested and lyophilized to analyze the carbon content in biomass by elemental analyzer (Elemental vario EL III, GmbH, Germany). The carbon contents in the initial and final algal biomass were marked as CIni. and CEnd (% DW), respectively; The initial and final biomass concentrations of algal biofilm were marked as DWIni. and DWEnd (g m-2), respectively. The net carbon element (Qcarbon, mole) that deposited inside the biofilm was calculated as: (1) 2 In equation #1, the figures 0.016 and 12 meant the area of algal biofilm in each chamber (m ) and the mole mass of carbon element (g mole-1), respectively. The minimum CO2 gas volume (VCO2, liter) that required for each chamber during cultivation could be calculated according to the ideal gas law: (2) In equation #2, the figures 8.314, 302.15 and 100 represented the ideal gas constant, temperature in kelvin and gas pressure in kilo Pascal, respectively. The minimum aeration rate (A mini, ml min-1) was calculated as: (3) It should be noticed that the carbon content in medium including Na2CO3 (one of the medium component and could be used as carbon resource) and secreted organic molecules if any, is not considered when calculating the Amini. Supplementary Table 1 Stoichiometric calculation of carbon element that deposited in algal biofilma Parameters Value -2 10.7 Green cells -2 End biomass (DWEnd, g m ) 52.7 Red cells after 7 days of cultivation Initial C content (CIni, % DW) 49.5 End C content (CEnd, % DW) 53 Net C gain (Qcarbon, mole) 0.03 Refer eq. 1 Minimum CO2 requirement (VCO2, l) 0.8 Refer eq. 2 Aeration CO2 concentration (CCO2, %) 1.5 Refer fig.4 5 Refer eq. 3 Initial biomass (DWIni, g m ) -1 Minimum aeration rate (Amini, ml min ) a The carbon source in medium, e.g. Na2CO3, was not considered in calculation. As shown in the table, the aeration should be at least 5 ml min-1 (with a CO2 concentration of 1.5%) to supply sufficient carbon to the biofilm. A lower speed will result in carbon deficiency. Accordingly, we set the 6 ml min-1 as the lower limit of the aeration. The 75 ml min-1 was selected as the upper limit because it could supply far beyond enough carbon source to the cultivation chamber, meanwhile, the water loss under this speed is not very high (ca. 15 ml d-1) so that the continuous cultivation need not to be interrupted frequently for water compensation.