CE 532 * Environmental Biotechnology

advertisement

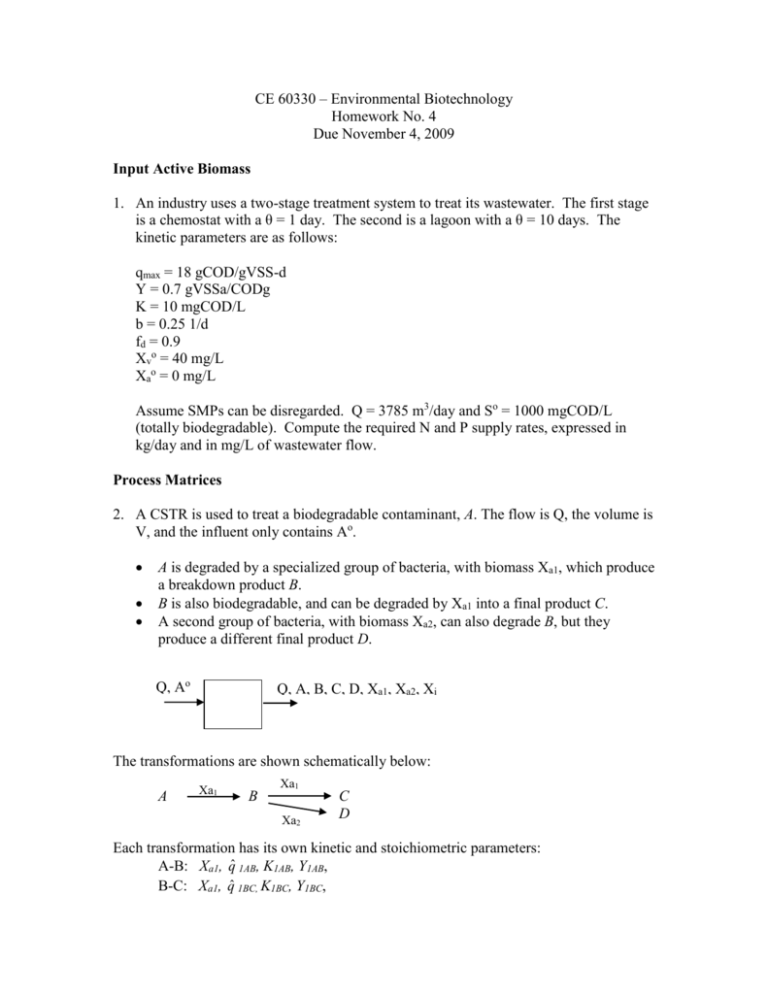

CE 60330 – Environmental Biotechnology Homework No. 4 Due November 4, 2009 Input Active Biomass 1. An industry uses a two-stage treatment system to treat its wastewater. The first stage is a chemostat with a θ = 1 day. The second is a lagoon with a θ = 10 days. The kinetic parameters are as follows: qmax = 18 gCOD/gVSS-d Y = 0.7 gVSSa/CODg K = 10 mgCOD/L b = 0.25 1/d fd = 0.9 Xvo = 40 mg/L Xao = 0 mg/L Assume SMPs can be disregarded. Q = 3785 m3/day and So = 1000 mgCOD/L (totally biodegradable). Compute the required N and P supply rates, expressed in kg/day and in mg/L of wastewater flow. Process Matrices 2. A CSTR is used to treat a biodegradable contaminant, A. The flow is Q, the volume is V, and the influent only contains Ao. A is degraded by a specialized group of bacteria, with biomass Xa1, which produce a breakdown product B. B is also biodegradable, and can be degraded by Xa1 into a final product C. A second group of bacteria, with biomass Xa2, can also degrade B, but they produce a different final product D. Q, Ao Q, A, B, C, D, Xa1, Xa2, Xi The transformations are shown schematically below: A Xa1 B Xa1 Xa2 C D Each transformation has its own kinetic and stoichiometric parameters: A-B: Xa1, q̂ 1AB, K1AB, Y1AB, B-C: Xa1, q̂ 1BC, K1BC, Y1BC, B-D: Xa2, q̂ 2BD, K2BD, Y2BD b (the decay term) is the same for all reactions fd (the degradable fraction) is the same for all reactions Assume the following stoichiometric conversions: 1 mg of A is transformed into 0.5 mg B, 1 mg of B is transformed into 1 mg of C 1 mg of B is transformed into 0.25 mg of D Assume 1) All transformation are aerobic, and that oxygen may be rate limiting 2) Compound B is self inhibitory with an inhibition constant KIB Write a process matrix for the above Biofilm Models 3. AQUASIM Biofilm Model. Set up the system a CMBR using AQUASIM (I will send you a file with the model). Determine the time required to reach steady state (constant effluent concentrations and biofilm thickness) if the initial biofilm thickness is 10 μm. The kinetic parameters are as follows: L = 0.01 cm K = 10 mg/L Xf = 10 mga/cm3 qmax =12 mgs/mga-d b’ = 0.1 1/d D = 1 cm2/d Df = 0.75 cm2/d Y=0.5 mga/mgs The input concentration is 200 mg/L. The flowrate is 1000 L/day, and the reactor volume is 100 L. The biofilm surface area is 44.5 m2.