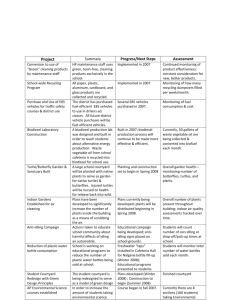

Lab Activity Biodiesel

advertisement

Biodiesel Materials 125 mL vegetable oil 25 mL methyl alcohol 1.2 g potassium hydroxide 3 beakers , 250 mL 1 beaker , 400 mL 1 large graduated cylinder 150 mL or more 1 small graduated cylinder 100 mL or less 2 plastic containers with caps that can hold 200 mL or more 1thermometer 1hotplate + magnetic stirrer 1 timer 1 scoop 1 normal funnel 1 pair of metal thongs 1 rubber beaker holder weighing paper 2 watch glasses- for burning 2 droppers – plastic pipetes – small 60 cm of string 1 scissors 1lighter NOTE : As you do the lab cite sources of experimental error. 1 Part 1 : Making Crude Biodiesel – Day 1 I . Making Potassium methoxide 1. Using an electronic balance and weighing paper, weigh out 1.2 g of potassium hydroxide 2. Obtain a 25 ml bottle of methyl alcohol. Remove the cap and add the potassium hydroxide to the bottle of methyl alcohol. 3. Tightly place the cap back on the bottle of methyl alcohol and shake the contents of the bottle for approximately 60 seconds. 4. After 60 seconds , loosen the cap of the bottle to release any pressure that may have developed. Re-tighten the cap and continue shaking. 5. Repeat as many times as necessary until the potassium hydroxide is completely dissolved. 6. After the potassium hydroxide is completely dissolved in the methyl alcohol, it is now called POTASSIUM METHOXIDE. Potassium methoxide reacts with the oil to produce the biodiesel esters and the glycerol. II. Setting up the Vegetable Oil – Adding the Potassium methoxide 7. Using the LARGE graduated cylinder, measure 125 mL of vegetable oil and place it in a 250 mL beaker. 8. Place the beaker on a hot plate. Add the small white magnetic stir bar and set the stir speed to medium- enough to stir well but not to splash. 9. Using the SMALL graduated cylinder, measure 20 mL of the Potassium methoxide and add this to the beaker of oil. Keep the remaining 5 mL in the bottle and replace the cap for later use. III. Making the Biodiesel – Heating the mixture 10. Turn on the heat of the hot plate and set to about 3000C. You set this temperature initially high because it takes a while to heat up the oil mixture. Use a thermometer and heat until it reads 55 - 600. Start timing at this point and you will need to heat for 20 minutes. Make sure the magnetic stir bar is stirring the mixture well. The temperature will fluctuate and you will need to reduce the temperature setting of hot plate down to about 800 more or less . You are trying to maintain a constant temperature between 55-600 for 20 minutes but this will be a little difficult. Read the thermometer constantly so you are getting close to the 55-600 range. Do the best you can but it doesn’t need to be exact. 2 11. After 20 minutes of heating is finished , remove the beaker with the rubber beaker holder so you don’t burn your self. Remove the white magnetic stir bar using metal thongs. Let the biodiesel mixture sit undisturbed for approximately 15 – 20 minutes. LEAVE THE HOT PLATE ON AND BE CAREFUL. IV. Separating the Biodiesel layer two times 12. After the 15- 20 minutes the mixture should separate into two distinct layers. You must now separate the top biodiesel layer from the bottom glycerol – oil layer. The DECANT method: simply pour the top layer ( decant) to a new clean 250 mL beaker. You do not need to get every single drop. 13. Leave the oil- glycerol layer behind and pour into the trash. Clean this beaker with soap and water well. 14. Place the newly made biodiesel back on to the hotplate. Add the white magnetic stir bar. Add the remaining 5 mL of Potassium methoxide and heat again: 55-600 for another 15 minutes. Constantly read the thermometer to maintain the 55-600 range. 15. Remove the beaker again ( using rubber beaker holder) , let sit undisturbed for about 10 minutes. 16. The mixture MAY or MAY NOT separate one more time. If it does, decant top layer. This is the purified biodiesel. 17. Place the purified biodiesel into a plastic container. 18. Should have about 100 mL of biodiesel. 3 Part 2 : “Washing” the Biodiesel two times– Day 2 1. Using a 400 mL beaker add about 250 mL of DISTILLED water from the container in the room. 2. Place on hot plate and heat to a “ lukewarm “ temperature of about 45 - 50 0 . Maintain temperature because you will be using this water a few times to “WASH” the biodiesel. 3. With a second identical plastic container to the container that holds the biodiesel, measure an amount of the LUKEWARM water that is equal to HALF the amount of the biodiesel. Doesn’t have to be exact but close. 4. Gently pour the lukewarm water into the biodiesel container and put the cap back on the biodiesel – water mixture. 5. Gently mix the water and biodiesel by slowly turning the container end – over – end for approximately 30 – 45 seconds. Do not mix the biodiesel – water mixture too roughly. After mixing , allow the biodiesel – water mixture to sit undisturbed. If done correctly and gentle like, the mixture should immediately begin separating into two layers. 6. Be patient and let it separate as much as possible. Some groups may take longer than others. After the biodiesel and water have separated, remove the biodiesel layer ( the decant method) into a clean beaker. You do not have to get every drop. Quality is important NOT quantity. Pour the cloudy water layer into the sink. Pour the biodiesel back into the container. 7. Repeat the washing procedure one more time adding HALF the amount of lukewarm water to the biodiesel, gently mix. 8. After you have finished “washing” the biodiesel , decant the final amount into a beaker. Heat the biodiesel to about 1200 for about 5 minutes using the hotplate. USE GOGGES and be careful. Make sure the small white magnetic stirrer is in the beaker. This final heating is to remove any excess water. 9. Finally, let the mixture cool and put into the plastic container. This is the final product of biodiesel! 4 Part 3 : “Burning” the Biodiesel – Day 3 Determining burning rate – which one burns faster? 1. Cut 2 pieces of string 10 cm long. 2. Put 2 droppers full of vegetable oil on to a watch glass and the same amount of biodiesel into another watch glass. 3. Soak one piece of string in the vegetable oil and one piece of string in the biodiesel. 4. Hold the string soaked in vegetable oil with the thongs and light it. Time how long it takes to burn out. Do the same for the string soaked in biodiesel. 5. Repeat the test one more time. 6. Record the values in the class data table. 5