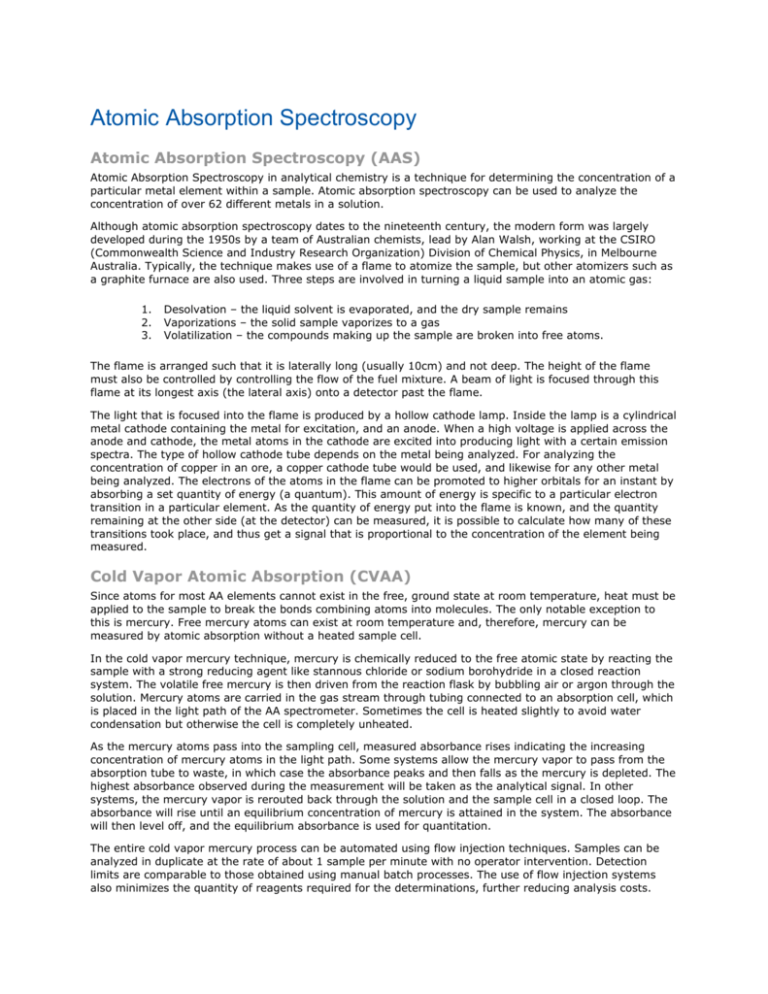

Atomic Absorption Spectroscopy (AAS)

advertisement

Atomic Absorption Spectroscopy Atomic Absorption Spectroscopy (AAS) Atomic Absorption Spectroscopy in analytical chemistry is a technique for determining the concentration of a particular metal element within a sample. Atomic absorption spectroscopy can be used to analyze the concentration of over 62 different metals in a solution. Although atomic absorption spectroscopy dates to the nineteenth century, the modern form was largely developed during the 1950s by a team of Australian chemists, lead by Alan Walsh, working at the CSIRO (Commonwealth Science and Industry Research Organization) Division of Chemical Physics, in Melbourne Australia. Typically, the technique makes use of a flame to atomize the sample, but other atomizers such as a graphite furnace are also used. Three steps are involved in turning a liquid sample into an atomic gas: 1. 2. 3. Desolvation – the liquid solvent is evaporated, and the dry sample remains Vaporizations – the solid sample vaporizes to a gas Volatilization – the compounds making up the sample are broken into free atoms. The flame is arranged such that it is laterally long (usually 10cm) and not deep. The height of the flame must also be controlled by controlling the flow of the fuel mixture. A beam of light is focused through this flame at its longest axis (the lateral axis) onto a detector past the flame. The light that is focused into the flame is produced by a hollow cathode lamp. Inside the lamp is a cylindrical metal cathode containing the metal for excitation, and an anode. When a high voltage is applied across the anode and cathode, the metal atoms in the cathode are excited into producing light with a certain emission spectra. The type of hollow cathode tube depends on the metal being analyzed. For analyzing the concentration of copper in an ore, a copper cathode tube would be used, and likewise for any other metal being analyzed. The electrons of the atoms in the flame can be promoted to higher orbitals for an instant by absorbing a set quantity of energy (a quantum). This amount of energy is specific to a particular electron transition in a particular element. As the quantity of energy put into the flame is known, and the quantity remaining at the other side (at the detector) can be measured, it is possible to calculate how many of these transitions took place, and thus get a signal that is proportional to the concentration of the element being measured. Cold Vapor Atomic Absorption (CVAA) Since atoms for most AA elements cannot exist in the free, ground state at room temperature, heat must be applied to the sample to break the bonds combining atoms into molecules. The only notable exception to this is mercury. Free mercury atoms can exist at room temperature and, therefore, mercury can be measured by atomic absorption without a heated sample cell. In the cold vapor mercury technique, mercury is chemically reduced to the free atomic state by reacting the sample with a strong reducing agent like stannous chloride or sodium borohydride in a closed reaction system. The volatile free mercury is then driven from the reaction flask by bubbling air or argon through the solution. Mercury atoms are carried in the gas stream through tubing connected to an absorption cell, which is placed in the light path of the AA spectrometer. Sometimes the cell is heated slightly to avoid water condensation but otherwise the cell is completely unheated. As the mercury atoms pass into the sampling cell, measured absorbance rises indicating the increasing concentration of mercury atoms in the light path. Some systems allow the mercury vapor to pass from the absorption tube to waste, in which case the absorbance peaks and then falls as the mercury is depleted. The highest absorbance observed during the measurement will be taken as the analytical signal. In other systems, the mercury vapor is rerouted back through the solution and the sample cell in a closed loop. The absorbance will rise until an equilibrium concentration of mercury is attained in the system. The absorbance will then level off, and the equilibrium absorbance is used for quantitation. The entire cold vapor mercury process can be automated using flow injection techniques. Samples can be analyzed in duplicate at the rate of about 1 sample per minute with no operator intervention. Detection limits are comparable to those obtained using manual batch processes. The use of flow injection systems also minimizes the quantity of reagents required for the determinations, further reducing analysis costs. The sensitivity of the cold vapor technique is far greater than can be achieved by conventional flame AA. This improved sensitivity is achieved, first of all, through a 100% sampling efficiency. All of the mercury in the sample solution placed in the reaction flask is chemically atomized and transported to the sample cell for measurement. The sensitivity can be further increased by using very large sample volumes. Since all of the mercury contained in the sample is released for measurement, increasing the sample volume means that more mercury atoms are available to be transported to the sample cell and measured. The detection limit for mercury by this cold vapor technique is approximately 0.02 µg/L. Although flow injection techniques use much smaller sample sizes. They provide similar performance capabilities, as the entire mercury signal generated is condensed into a much smaller time period relative to manual batch-type procedures. Flame Atomic Absorption (FLAA) Flame Atomic Absorption Spectroscopy is a fast and easy technique with an extremely high sensitivity (especially for elements like Pb, Cd, Cu and Cr), although problems can arise as a result of chemical (a much worse situation than with ICP-AES) and spectral interferences. The sample is atomized in the flame, through which radiation of a chosen wavelength (using a hollow cathode lamp) is sent. The amount of absorbed radiation is a quantitative measure for the concentration of the element to be analyzed. The most current gas mixtures used are air/acetylene and nitrousoxide/acetylene. The latter resulting in higher atomization efficiencies and thus better detection limits for elements like Si, Al, Sc, Ti, V and Zr. The air/acetylene flame can be used for easy atomizable elements (e.g. As and Se). Background correction can be achieved with a deuterium lamp although several disadvantages subsequently occur. A disadvantage of the AAS technique is the non linearity of the calibration curves when absorbance becomes higher than 0.5 to 1. The relative standard deviations are between 0.3 and 1% for absorbances of 0.1 to 0.2. Detection limits for flame AAS vary enormously: from 1 - 5 ppb (e.g. Ca, Cd, Cr, Cu) to more than 1000 ppb (e.g. P). Some elements (e.g. B, C, Br) cannot be measured at all. Overview of Technique In flame atomic absorption spectroscopy a liquid sample is aspirated and mixed as an aerosol with combustible gasses (acetylene and air or acetylene and nitrous oxide.) The mixture is ignited in a flame of temperature ranging from 2100 to 2800 degrees C (depending on the fuel gas used.) During combustion, atoms of the element of interest in the sample are reduced to the atomic state. A light beam from a lamp whose cathode is made of the element being determined is passed through the flame into a monochronometer and detector. Free, unexcited ground state atoms of the element absorb light at characteristic wavelengths; this reduction of the light energy at the analytical wavelength is a measure of the amount of the element in the sample. Specific Sample Considerations Plant: solid samples must be in liquid form to be aspirated by the instrument. Therefore, solid material must be liquefied by means of some form of extract or digest protocol. Procedures have been devised that make the total amount of an element in the sample available for assay or that use some particular property to extract that portion of the element which exists in some chemical forms but not in others. The [plant dry ash/double acid] extraction method determines the total element content of the sample. Soil: for ecological purposes there is more interest in measures of extractable or labile soil constituents than in total element content. Certain partitions of the total soil content of a given element are operationally defined by an extraction procedure, and arguments are usually offered that these partitions, so defined, correspond to different levels of biological availability or activity. The [HCl/H2SO4 double acid] extraction method, also referred to as North Carolina and Mehlich-1, is widely used to determine bioavailable Ca, K, Mg, Mn, P, and Zn in sandy acid soils characteristic of the eastern and southeastern United States. Water: aquatic samples of course need no liquefaction step, but researchers must still decide which analyte partition (dissolved, suspended, total) is of interest. Differing treatments of each sample partition are detailed in the U.S. EPA's discussion of [Content partitioning] of water samples. Graphite Furnace Atomic Absorption (GFAA) Graphite furnace atomic absorption spectrometry is a highly sensitive spectroscopic technique that provides excellent detection limits for measuring concentrations of metals in aqueous and solid samples. GFAA has been used primarily in the field for the analysis of metals in water. GFAA could be used to determine metals in soil, but the sample preparation for metals in soil is extensive and is not practical for field applications. GFAA cannot be described as a truly field portable instrument. GFAA instruments are extremely sensitive and therefore, must be operated in a clean, climate controlled environment. This can be difficult but not impossible to achieve in a field environment. In addition, the 220-volt electrical power requirement often precludes remote operation. However, GFAA is an example of “taking the laboratory to the field.” Miniaturization of electronics has significantly reduced instrument size and weight, making it easier to use the instrument in a field laboratory. In atomic absorption (AA) spectrometry, light of a specific wavelength is passed through the atomic vapor of an element of interest, and measurement is made of the attenuation of the intensity of the light as a result of absorption. Quantitative analysis by AA depends on: (1) accurate measurement of the intensity of the light and (2) the assumption that the radiation absorbed is proportional to atomic concentration. Samples to be analyzed by AA must be vaporized or atomized, typically by using a flame or graphite furnace. The graphite furnace is an electrothermal atomizer system that can produce temperatures as high as 3,000°C. The heated graphite furnace provides the thermal energy to break chemical bonds within the sample and produce free ground-state atoms. Ground-state atoms then are capable of absorbing energy, in the form of light, and are elevated to an excited state. The amount of light energy absorbed increases as the concentration of the selected element increases. GFAA has been used primarily for analysis of low concentrations of metals in samples of water. GFAA can be used to determine concentrations of metals in soil, but the sample preparation for metals in soil is somewhat extensive and may require the use of a mobile laboratory. The more sophisticated GFAAs have a number of lamps and therefore are capable of simultaneous and automatic determinations for more than one element. Logistical needs include reagents for preparation and analysis of samples, matrix modifiers, a cooling system, and a 220-volt source of electricity. In addition, many analytical components of the GFAA system require significant space, which typically is provided by a mobile laboratory. The advantages of GFAA spectrometry include: Greater sensitivity and detection limits than other methods Direct analysis of some types of liquid samples Low spectral interference Very small sample size Inductively Coupled Plasma – Mass Spectroscopy (ICP-MS) The Inductively Coupled Plasma coupled with a mass spectrograph give very high sensitivity for the determination of elements and even isotopes. This technique has the ability to detect very low levels (parts per billion) of most elements in a sample. The dynamic range is typically ten orders of magnitude and data reduction is relatively simple. Rapid data acquisition and data reduction enable the measurement of large numbers of samples in a short period of time. ICP-MS is the technique of choice for trace element analysis of natural waters, minerals, and rocks. High precision is achieved by using multiple internal standards. Inductively Coupled Plasma – Optical Emission Spectroscopy (ICPOES) Inductively coupled plasma optical emission spectroscopy is a major technique for elemental analysis. The sample to be analyzed, if solid, is normally first dissolved and then mixed with water before being fed into the plasma. Atoms in the plasma emit light (photons) with characteristic wavelengths for each element. This light is recorded by one or more optical spectrometers and when calibrated against standards the technique provides a quantitative analysis of the original sample. ICP instruments comprise various optical spectrometers, nebulizers (including glass concentric, parallel flow, JY pneumatic, cross flow, V groove, micro concentric, ultrasonic, CMA), spray chambers, ICP torch, and RF generators. Fourier Transform Infrared (FTIR) FTIR spectrometers record the interaction of IR radiation with a sample, measuring the frequencies at which the sample absorbs the radiation and the intensities of the absorption. Determining these frequencies allows identification of the sample's chemical make-up, since chemical functional groups are known to absorb radiation at specific frequencies. The intensity of the absorption is related to the concentration of the component. Intensity and frequency of sample absorption are depicted in a two-dimensional plot called a spectrum. Intensity is generally reported in terms of percent transmittance, the amount of light that passes through it. In the interferometer the light passes through a beam splitter, which sends the light in two directions at right angles. One beam goes to a stationary mirror then back to the beam splitter. The other goes to a moving mirror. The motion of the mirror makes the total path length variable versus that taken by the stationary-mirror beam. When the two meet up again at the beam splitter, they recombine, but the difference in path lengths creates constructive and destructive interference pattern called an interferogram. The recombined beam passes through the sample. The sample absorbs all the different wavelengths characteristic of its spectrum, and this subtracts specific wavelengths from the interferogram. The detector now reports variation in energy versus time for all wavelengths simultaneously. A laser beam is superimposed to provide a reference for the instrument operation.