X-ray mapping of interfacial regions for graphite brazed ferrous

advertisement

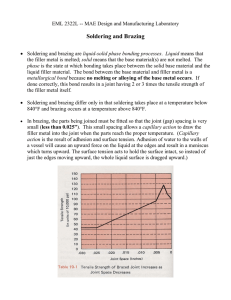

X-ray mapping of interfacial regions for graphite brazed ferrous composites P.G. Huggett1, R. Wuhrer2 1Materials Solutions Pty Ltd, Canning Vale, 6155, Australia; 2Advanced Materials Characterisation Facility, University of Western Sydney, Rydalmere, 2116, Australia e: paul@materialssolutions.com.au Abstract A new method has been developed for brazing white cast irons and other ferrous alloys to steel or ferrous substrates without the need to pre-machine the surfaces to be brazed. Standard alloy brazing processes typically require adjoining surfaces to be machined within tight tolerances, to enable capillary flow of the brazing alloy. The new brazing process uses graphite as the brazing medium, and can be used effectively on as-cast surfaces and “black” steel bar sections to result in an excellent metallurgical bond between the two components being joined. X-ray mapping has been used to study the graphite joining process. The x-ray mapping allows the diffusion of elements within the interface regions to be studied. Particular interest from the x-ray mapping was the detection of any non-metallic inclusions that may be present at the interface as a result of using “as-cast” surfaces in the joints. The results of the x-ray mapping show the graphite based brazing produces a defect free interface region with negligible non-metallic inclusions present, and substantial diffusion of alloying elements such as chromium across the interface.