Waterproofing And Transition

advertisement

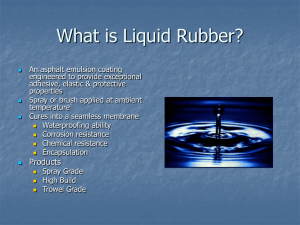

Fox Blocks Airlite Plastics Co. 6110 Abbott Street Omaha, NE 68110 877.369.2562 www.FoxBlocks.com Waterproofing and Transition Fox Blocks stay-in-place insulating concrete forms (ICFs) are used in all types of residential and commercial applications. Fox Block ICF walls provide unparalleled energy efficiency, safety, durability and comfort. Fox Block ICFs features a flat interior configuration. It contains plastic polypropylene ties or studs that hold the form together during concrete placement and later serve as the furring strips for fastening interior and exterior finishes. Building with Fox Block Walls Proper waterproofing is critical to ensuring a dry basement. Each step in the waterproofing and transition process is important; it is not an area in which to cut corners or try to save money. You can't rely on the EPS foam and concrete to prevent water leakage, and if leakage occurs, it can damage your reputation as a builder. Water problems are difficult and expensive to find and fix, so it's better to prevent them from occurring in the first place. The contractor, designer and owner must share in the responsibility of choosing the proper waterproofing product and installing the waterproofing properly. Components of Ensuring a Dry Interior Basement Water Sealant System – It is critical to NOT use any solvent, ketone, ester or petroleum-based water sealant products. These types of materials will "eat-away" or deteriorate the expanded polystyrene (EPS) foam. Make sure that the product used is compatible with EPS. It is a requirement for Fox Block walls to be covered with a water sealant system on below grade applications. There are basically three types of water sealant systems available for ICF walls—brush, roll, spray, or trowel-on rubber coating systems; air gap and peel and stick contact membrane systems; and drainage membrane systems. Some of the variables that should be considered when choosing a waterproofing system include: the local soil type, the local climate, the ground water conditions and the specific building and project requirements. Fox Blocks recommends either the air gap or drainage type systems. Fox Blocks does not recommend the spray, brush, or trowel-on waterproofing systems for the following reasons: They typically do not hold up as well over time They dry to a lower mil coverage They do not cover gaps in the wall They may have small pin-holes in the membrane. While there are many different products on the market, Fox Blocks specifically recommends the following waterproofing membrane systems or an equivalent: Fox Blocks Airlite Plastics Co. 6110 Abbott Street Omaha, NE 68110 877.369.2562 www.FoxBlocks.com 1. Cosella-Dörken’s Delta MS (or equivalent) This is an air gap waterproofing membrane system. It is a tough, dimpled 24-mil high-density polyethylene wrap that seals out water and bridges inevitable foundation gaps. It has full code approval with Canadian evaluation reports. If any moisture gets behind the Delta MS it will self drain to the footing and drain tile. The dimpled side must be installed facing the foundation wall. The Delta MS system comes in rolls and is installed by wrapping the foundation wall and mechanically fastening it with course thread screws near the top of the foundation wall with speed clips at every plastic stud. No damp proofing spray is required. Follow Cosella-Dörken’s attached installation guidelines for the Delta MS system. 2. Polyguard’s Polyguard 650 System This option should be used only in areas where there are termite concerns. Polyguard’s 650 ICF peel and stick waterproofing membrane is a 60-mil self-adhering membrane consisting of 56 mils of rubberized asphalt laminated to 4 mils of polyethylene. It is available in rolls of 4' x 50' (4.22 x 15.24 m) or 39.36" x 61' (12 x 18.6 m). Polyguard also offers a 650XTM or 650XTP product. These two products provide both waterproofing and termite protection. For very heavy, hard-to-drain soils, Fox recommends that you use the Polyguard 15P drain system in addition to the 650 waterproofing membrane. This system will relieve hydrostatic pressure. Follow Polyguard’s installation guidelines. 3. Resisto by Colphene Soprema – a peel and stick self adhered membrane It is essential to follow the waterproofing manufacturers' application procedures. The membrane systems work especially well, because they effectively cover the seams of the block. They should be applied either horizontally or vertically down the wall with the required overlap. The top edge and all termination points of the water sealant membrane must be properly sealed. The drainage type membrane systems offer a release to the hydrostatic water pressures. Make sure that the water sealant system is extended over the top of brick ledges and footings. Drain Tile System - It is important to install a drain tile system. This acts as a below-grade gutter system that removes water from the base of the building. The drain tile system may be placed at the base of the footing or slab on either the exterior or interior or both sides of the wall. It must be placed at an elevation lower than the slab. Fox Blocks offers a list of contacts for different types of drain tile systems. Backfill and Grade – Place aggregate below and above the drain tile system. Make sure either a floor system is installed and/or the top of the wall is adequately braced before backfilling. The backfill should be lightly compacted to avoid settlement. As the site is backfilled make sure the grade is sloped away from the building in all directions. Use extreme care when backfilling so that the backfill or equipment does not puncture a hole in the water sealant system. If rocky soil or dry clay soil is being backfilled, Fox Blocks recommends that you install a protective membrane in front of the water sealant system to avoid puncturing the membrane. Caulking, Flashing and Sealing – Caulking, flashing and sealing is imperative to avoid water problems. Wherever flashing is required in traditional construction is also required with Reward walls. Water that gets behind a water sealant system, a deck, doors and windows and penetrations through the wall for example will find its way inside. Guttering and Downspouts – Install guttering and downspouts on the Fox building to direct water away from the building. Fox Blocks Airlite Plastics Co. 6110 Abbott Street Omaha, NE 68110 877.369.2562 www.FoxBlocks.com Stacking Reward Forms and Placing Concrete - When stacking Fox Block forms, stack them loosely enough to allow the forms to stretch when the weight of the concrete is being placed, but not so loose that there are gaps between the forms. This will help builders achieve straight walls, while not inviting water into the building. Finally, always follow Fox Blocks recommendations for the concrete mix and concrete placement to ensure that there are no voids and honeycombing within the concrete walls. The concrete mix should consist of a 5.5" to 6.5"(139.7 to 165.1 mm) slump with a maximum aggregate size of 3/8" to 1/2" (9.53 to 12.7 mm). When building with Fox Block ICFs there are two areas to pay particular attention to when placing concrete and consolidating the concrete: The vertical seams between forms where two plastic ties are located close to each other The area next to and below door and window bucks where a plastic tie may be close to the buck. Do not be afraid to remove a plastic tie close to a buck as long as proper bracing is installed to keep the form from blowing out. Transition Area With ICF construction there will almost always be a transition area on the wall where the EPS foam is exposed above grade. Transition could occur on a Fox Block basement wall with wood frame, one- or two-story upper floors, as well as on a Fox Blocks basement wall with above-grade ICF walls. No EPS foam can be left uncovered, so the exposed between the waterproofing membrane and the exterior finish must be covered with some compatible finish. The waterproofing membrane typically will terminate slightly below grade and follow the grade line. The exterior finish may consist of brick or stone veneer, siding or stucco. Each of these is finished slightly differently, but in the same general way. Typically you make sure the exterior finish above grade overlaps the transition material and that the transition material overlaps the waterproofing material. Any moisture must be able to drain down without getting behind any finish material that is on the Fox Block wall. Some common materials used to finish the EPS foam in the transition area include Tuff II by Total Wall, Protecto Wrap, acrylic or Portland cement based stucco or parging material. Protecto Wrap is a tough self-adhesive membrane material. For the stucco and parging materials, Fox Blocks recommends that you choose one that offers the best impact resistance and waterproofing resistance. Acrylic stucco must be used with a fiberglass mesh. Portland cementbased stucco and parging must utilize a metal lath. With brick veneer as the substrate, it is important to have an adequate air gap behind the brick veneer and weep holes in the brick veneer to remove any moisture that gets behind the brick. Fox Blocks also recommends that either flashing or a waterproofing membrane be placed up and over the brick ledge and up the wall a few inches. With siding as the substrate it is important to follow the overlap guidelines discussed above. The siding must overlap the transition material and the transition material must overlap the waterproofing membrane. With stucco as the substrate, it is important to overlap the stucco with the waterproofing membrane.