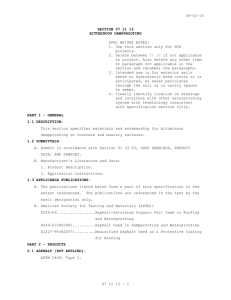

Division 7 – Thermal & Moisture Protection Waterproofing 07100

advertisement

Division 7 – Thermal & Moisture Protection Waterproofing 07100 Refer to Samet Corporation standard details and standards Before waterproofing or dampproofing subcontractor is allowed to commence his work, see that: a. Surfaces are free from foreign material. b. Excess mortar or concrete is removed; all holes, joints and cracks are pointed and rough or high spots are ground smooth. c. Wood nailers or other attachment conditions are adequate. d. Surfaces are dry to receive heated asphalt, coal tar or other membrane. Check for dampness if necessary. e. Special conditions are provided as required at corners, intersections, and connections to existing works. Damp surfaces may be allowed for coal tar emulsions, asphalt emulsions, and polyvinyl acetate emulsions if no surface water film is present. Installation should not proceed if temperature is below 40 degree F or weather is damp or foggy. Hot-applied bituminous materials are not overheated. If asphalt is being used, heated requirements is EVT, plus or minus 25 degree F, at point of application. (EVT Equiviscous Temperature is the temperature at which asphalt will attain a viscosity of 125 centistokes which is the practical and optimum temperature for wetting and fusion at the point of application). In the event EVT information is not furnished by the manufacturer, the following maximum heating temperatures should be used as guidelines: Dead Level Asphalt………Type I 475 degree F maximum Flat Grade Asphalt………. Type II 500 degree F maximum Steep Grade Asphalt…….. Type III 525 degree F maximum Special Steep Asphalt…… Type IV 525 degree F maximum In no case should kettle or tanker be heated above flash point. Do not exceed final blowing temperature for more than four hours. Kettle temperature is observed. Method and sequence of transporting and application of bituminous material are adequate. Surfaces are properly primed if required. Pipes, ducts, conduits, and other items penetrating membrane are flashed or made watertight as required. Membrane details are understood. Observe details for turning up membrane, stripping around penetrations, membrane lapping, etc. See that both inside and outside corners are treated as required by the specifications. Joinery between each day’s work is adequate. No work proceeds during damp weather. Allow no moisture to be present between layers. Stored materials are protected against moisture. Proper nails, adhesives and fastenings are used. Samet Corporation | Building Structures. Building Relationships. Division 7 – Thermal & Moisture Protection Waterproofing 07100 Application provides coverage and quantities of materials as required. Top edge is secured and flashed as required. Felts are applied as required: no felt touching felt, full mopping of asphalt to ply lines, and no “fish mouths” or buckles. Protective covering is provided and installed as required and backfilling takes place immediately. Covering remains in place during backfilling. Installation is protected from damage by other trades or by general contractor during installation and following completion. If subject to heavy traffic, movement of equipment, plywood sheets or other protection should be provided. Synthetic or rubber single-ply membranes are installed by approved contractors and strictly according to manufacturers’ specifications if required. COMMENTS: Waterproofing is to be performed by a professional waterproofing contractor with warranties is place. All pits are to be waterproofed below grade. Many waterproofing materials are flammable and safety precautions are to be reviewed prior to work starting. Smoking, torches and other potential ignition sources should be identified. Waterproofing should cover walls and onto footings and internal seals may be required in cast in place concrete. Samet Corporation | Building Structures. Building Relationships.