LIGNITE-FIRES

advertisement

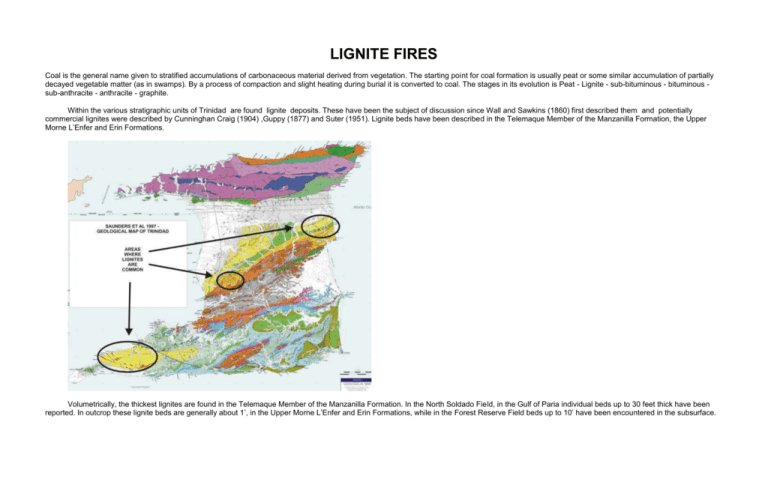

LIGNITE FIRES Coal is the general name given to stratified accumulations of carbonaceous material derived from vegetation. The starting point for coal formation is usually peat or some similar accumulation of partially decayed vegetable matter (as in swamps). By a process of compaction and slight heating during burial it is converted to coal. The stages in its evolution is Peat - Lignite - sub-bituminous - bituminous sub-anthracite - anthracite - graphite. Within the various stratigraphic units of Trinidad are found lignite deposits. These have been the subject of discussion since Wall and Sawkins (1860) first described them and potentially commercial lignites were described by Cunninghan Craig (1904) ,Guppy (1877) and Suter (1951). Lignite beds have been described in the Telemaque Member of the Manzanilla Formation, the Upper Morne L’Enfer and Erin Formations. Volumetrically, the thickest lignites are found in the Telemaque Member of the Manzanilla Formation. In the North Soldado Field, in the Gulf of Paria individual beds up to 30 feet thick have been reported. In outcrop these lignite beds are generally about 1’, in the Upper Morne L’Enfer and Erin Formations, while in the Forest Reserve Field beds up to 10’ have been encountered in the subsurface. At an outcrop of the Telemaque member of the Manzanilla Formation in the Forres Park area, are exposed four coarsening upwards cycles each capped by a thin ( less than 1’ thick) lignite bed. The base of these lignite beds are clearly erosional an internally the lignite shows sedimentary structures suggesting they were resedimented from nearby deposits. Also of note no rooted zone is present . At Guapo Bay, the area closest to the Vessigny Beach Facility has a lignite bed 1-2 ‘ thick exposed that is overlain in places by a porcellanite The lignite bed is dominantly organic material with leaf imprints ) and tree trunks in random orientations and growth positions . The lower contact of these beds is variable, in places it is clearly erosional and in others the underlying claystone beds have rooted zones . The lignite rich bed grades upwards into parallel bedded claystone ) and siltstones that have numerous leaf impressions parallel to the laminations. The only diference between these beds and the underlying lignite being the clay content. The second and thickest lignite unit (12’) at Guapo Bay is a composite unit made up of 3 beds with lower erosional contacts , the upper two being separated by a clay filled channel deposit/plug. Within all of the beds the lignites are of parallel laminated organic material, dominantly of leaf and grass origin. The upper most bed grades upward ( into a parallel laminated leaf rich claystone . Leaves appear to be Rhizophora (red mangrove). It is only within the Erin Formation on the western side of Quoin Cliff that we see a thin lignite bed with tree trunks in growth positions . At Chatham (White Cliff) there are a number of lignite beds, the outcrop closest to the old hotel exposes a large channel complex about 200’ in width. The base of the lowest channel rests on a thinly layered (2’) lignite in which plant material is visible as are occasional woody fragments. At the eastern end of the channel, another channel has eroded into the margin. Sediments at this edge are lignitic and were probably redeposited in a slack water area after being eroded from elsewhere. Further east is another outcrop with a strike section of a lignite. The base of the outcrop is a pure claystone with NO rooted zone. There is an abrupt change upwards into a ligntic claystone 2’ thick, another abrupt change to pure hard lignite 1’ thick and finally back into another lignitic claystone. Two possible origins will be reviewed for the lignites observed in outcrops at Guapo Bay, Chatham, Quoin Cliff and Frank Bay. The first involves an insitu origin within mangrove and sedge swamps developed behind estuarine sand barrier bars and spits While the other involves erosion and resedimentation. What are these lignites composed of? G.W. Halse (1937) reported a Mr. McCallum had analysed the lignites at Cedros Point and showed that they are made up of: Water (loss on drying to 1300C) – 5.3% Water & Organic matter (loss on ignition) – 16.1% Organic matter by diference – 10.8% Sulphur – 1.86% A lignite seam fire is the underground smouldering of a lignite deposit. Such fires have economic, social and ecological impacts. They are often started by lightning, grass, or forest fires, and are particularly insidious because they continue to smoulder underground after surface fires have been extinguished, sometimes for many years, before flaring up and restarting forest and brush fires nearby. They propagate in a creeping fashion along mine shafts and cracks in geologic structures. Lignite and Coal fires are a serious problem because hazards to health and safety and the environment include toxic fumes, reigniting grass, brush, or forest fires, and subsidence of surface infrastructure such as roads, pipelines, electric lines, bridge supports, buildings and homes. Whether started by humans or by natural causes, coal seam fires continue to burn for decades or even centuries until either the fuel source is exhausted; a permanent groundwater table is encountered; the depth of the burn becomes greater than the ground’s capacity to subside and vent; or humans intervene. Because they burn underground, coal seam fires are extremely difficult and costly to extinguish, and are unlikely to be suppressed by rainfall. There are strong similarities between coal fires and peat fires. Some fires along lignite or coal seams are natural occurrences. Some coals may self-ignite at temperatures as low as 40 °C (104 °F) for brown coal in the right conditions of moisture and grain size. The fire usually begins a few decimeters inside the coal at a depth in which the permeability of the coal allows the inflow of air but in which the ventilation does not remove the heat which is generated. Two basic factors determine whether spontaneous combustion occurs or not, the ambient temperature and the grain size: The higher the ambient temperature, the faster the oxidation reactions and the greater the heat release inside the grain. The larger the grain, the harder it is for the heat arising on the inside to be dissipated to the outside, i.e., the faster the spontaneous combustion. The poor heat loss is because the porous or crushed material usually has low thermal conductivity; it acts like insulation. Bushfires (lightning-caused, agricultural or arson) can ignite the coal closer to the surface , and the smouldering fire can spread through the seam, creating subsidence that may open further seams to oxygen and spawn future wildfires when the fire breaks to the surface. Prehistoric clinker outcrops in the American West are the result of prehistoric coal fires that left a residue that resists erosion better than the matrix, leaving buttes and mesa. It is estimated that Australia's Burning Mountain, the oldest known coal fire, has burned for 6,000 years.Globally, thousands of inextinguishable mine fires are burning, especially in China and India, where poverty, lack of government regulations and runaway development combine to create an environmental disaster. The 2003 Chatham Fire - Photos by C. Archie Lignite outcropping on the surface Lignite burning Close up of the lignite Land collapsing due to consumption of the subsurface lignite Baked clays Sulphur crystals being re-precipitated on the surface when hot vapours cool. Sulphur coating lignite found in Chatham Sick on Sulphur H. Vincent, 2004 June 2003 – Report made to Environment Management Authority (EMA) of continuous rising smoke, with “smelly odour.” • • • • • • • • • • July 27th 2003 – EMA and Ministry of Energy (MOE) visit site. Burning lignite bed diagnosed By October 2003, hopes of fire extinguishing on its own did not transpire. November 4th 2003 - EMA monitors air quality at indoor locations in surrounding areas (<400m away) Unacceptable levels of sulphur dioxide present Health authorities mobilized NEMA consulted on possible evacuation Fire services consulted to extinguish burn GSTT also consulted for technical advice Ministry of Works mobilized to assist in extinguishing efforts. The "Burning Cliff" at Cedros - G.W. Halse (1937) A fire at Cedros which started in 1933 and was still burning 2 years later. Extinguishing coal fires In order to thrive, a fire requires fuel and oxygen. Firefighting involves finding an appropriate methodology which addresses the interaction of these two factors for the specific fire in question. A fire can be isolated from its fuel source, for example through firebreaks or fireproof barriers. Many fires, particularly those on steep slopes, can be completely excavated. In the case of near-surface coal seam fires, the influx of oxygen in the air can be interrupted by covering the area or installing gas-tight barriers. Another possibility is to hinder the outflow of combustion gases so that the fire is quenched by its own exhaust fumes. Energy can be removed by cooling, usually by injecting large amounts of water. However, if any remaining dry coal absorbs water, the resulting heat of absorption can lead to re-ignition of a once-quenched fire as the area dries. Accordingly, more energy must be removed than the fire generates. In practice these methods are combined, and each case depends on the resources available. This is especially true for water, for example in arid regions, and for covering material, such as loess or clay, to prevent contact with the atmosphere. Extinguishing underground coal fires, which sometimes exceed temperatures of 540°C (1,000°F), is both highly dangerous and very expensive. Near-surface coal seam fires are routinely extinguished in China following a standard method basically consisting of the following phases: Smoothing the surface above the fire with heavy equipment to make it fit for traffic. Drilling holes in the fire zone about 20 m apart down to the source of the fire, following a regular grid. Injecting water or mud in the boreholes long term, usually 1 to 2 years. Covering the entire area with an impermeable layer about 1 m thick, e.g., of loess. Planting vegetation to the extent the climate allows. Efforts are underway to refine this method, for example with additives to the quenching water or with alternative extinguishing agents. Underground coal seam fires are customarily quenched by inertization through mine rescue personnel. Toward this end the affected area is isolated by dam constructions in the galleries. Then an inert gas, usually nitrogen, is introduced for a period of time, usually making use of available pipelines.