bbb1575-sup-0001-AppendixS1

advertisement

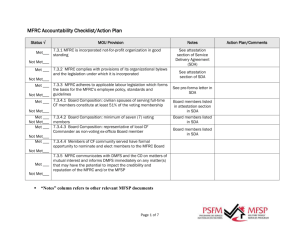

Supplementary Material Strategic supply system design—a holistic evaluation of operational and production cost for a biorefinery supply chain Strategic biorefinery feedstock supply system design Patrick Lamers1,*, Eric C.D. Tan2, Erin M. Searcy1, Christopher J. Scarlata2, Kara G. Cafferty3, Jacob J. Jacobson4 1 Idaho National Laboratory, Idaho Falls, ID 83415, USA National Renewable Energy Laboratory, Golden, CO 80401, USA 3 CH2M, Corvallis, OR 97331, USA 4 Mind’s Eye Computing, Idaho Falls, ID 83415, USA * Corresponding author: patrick.lamers@inl.gov; pa.lamers@gmail.com 2 Figure S 1. Grinding costs are a function of grinding energy needed for corn stover of various moisture contents. Current biochemical conversion pathway design case assumption is 20% moisture content. Strategic supply system design—a holistic evaluation of operational and production cost for a biorefinery supply chain Figure S 2. The impact of dry matter loss on bale ash content and final conversion efficiency based on a 35% initial moisture and 10% ash .11 The relative % of ash increases as the bale loses moisture. The storage consists of six bale high stacks covered with tarp at field side or a similar ‘unimproved’ storage site. Table S 1. Conversion factors and assumptions. Gasoline heating value Gasoline heating value Biochemical Thermochemical 2011$ per 2007$ Metric tonnes per short ton 46.54 MJ/kg 124,340 btu/gal 1.521 LGE/MFSP 1.517 LGE/MFSP 1.115 0.907 Strategic supply system design—a holistic evaluation of operational and production cost for a biorefinery supply chain Table S 2. Biochemical conversion details. Case 1 Corn Stover (Conventional) BC Refinery Scale (Dry Tonnes/Day) Feedstock type Feedstock logistics Feedstock form Minimum fuel selling price, MFSP ($/liter) Liter Gasoline-Equivalent MFSP, ($/LGE) Total installed cost ($MM) Total project investment ($MM) Delivered feedstock cost ($/dry tonne) Ethanol production (MM liter/yr) Ethanol yield (liter/dry tonne) BC Refinery Scale (Dry Tonnes/Day) Feedstock type Feedstock logistics Feedstock form Minimum fuel selling price, MFSP ($/liter) Liter Gasoline-Equivalent MFSP, ($/LGE) Total installed cost ($MM) Total project investment ($MM) Delivered feedstock cost ($/dry tonne) Ethanol production (MM liter/yr) Ethanol yield (liter/dry tonne) 500 Corn Stover Conventional Bale $1.01 $1.54 $106 $194 $98.31 57.7 329.2 1000 Corn Stover Conventional Bale $0.84 $1.27 $162 $295 $98.31 115.4 329.3 2000 Corn Stover Conventional Bale $0.72 $1.10 $252 $459 $98.31 230.8 329.3 500 Corn Stover Advanced Pellet $0.92 $1.40 $108.80 $199.10 $98.31 66.4 378.9 Case 2 Corn Stover (Advanced) 1000 2000 Corn Stover Corn Stover Advanced Advanced Pellet Pellet $0.76 $0.66 $1.16 $1.01 $164.87 $257.51 $301.32 $470.32 $98.31 $98.31 132.8 265.6 379.0 379.0 5000 Corn Stover Advanced Pellet $0.58 $0.88 $472.22 $864.73 $98.31 664.0 379.0 7500 Corn Stover Advanced Pellet $0.55 $0.84 $625.94 $1,148.32 $98.31 995.9 378.9 10000 Corn Stover Advanced Pellet $0.54 $0.82 $763.95 $1,402.94 $98.31 1327.8 378.9 Strategic supply system design—a holistic evaluation of operational and production cost for a biorefinery supply chain Biorefinery Size (2000 Dry Tonnes/day) Feedstock Ash Content (Dry wt%) Feedstock type Feedstock logistics Feedstock form Minimum fuel selling price, MFSP ($/liter) Liter Gasoline-Equivalent MFSP, ($/LGE) Total installed cost ($MM) Total project investment ($MM) Delivered feedstock cost ($/dry tonne) Ethanol production (MM liter/yr) Ethanol yield (liter/dry tonne) Case 3 Corn Stover (Conventional) - various ash contents 5% 7% 9% 11% Corn Stover Corn Stover Corn Stover Corn Stover Advanced Advanced Advanced Advanced Pellet Pellet Pellet Pellet $0.67 $0.69 $0.71 $0.72 $1.02 $1.05 $1.07 $1.10 $258.18 $256.51 $254.84 $251.60 $470.21 $467.76 $465.19 $459.06 $98.31 $98.31 $98.31 $98.31 246.5 241.2 236.1 230.8 351.7 344.2 336.8 329.3 13% Corn Stover Advanced Pellet $0.74 $1.12 $250.04 $456.50 $98.31 225.6 321.8 15% Corn Stover Advanced Pellet $0.76 $1.15 $248.82 $454.16 $98.31 220.3 314.4