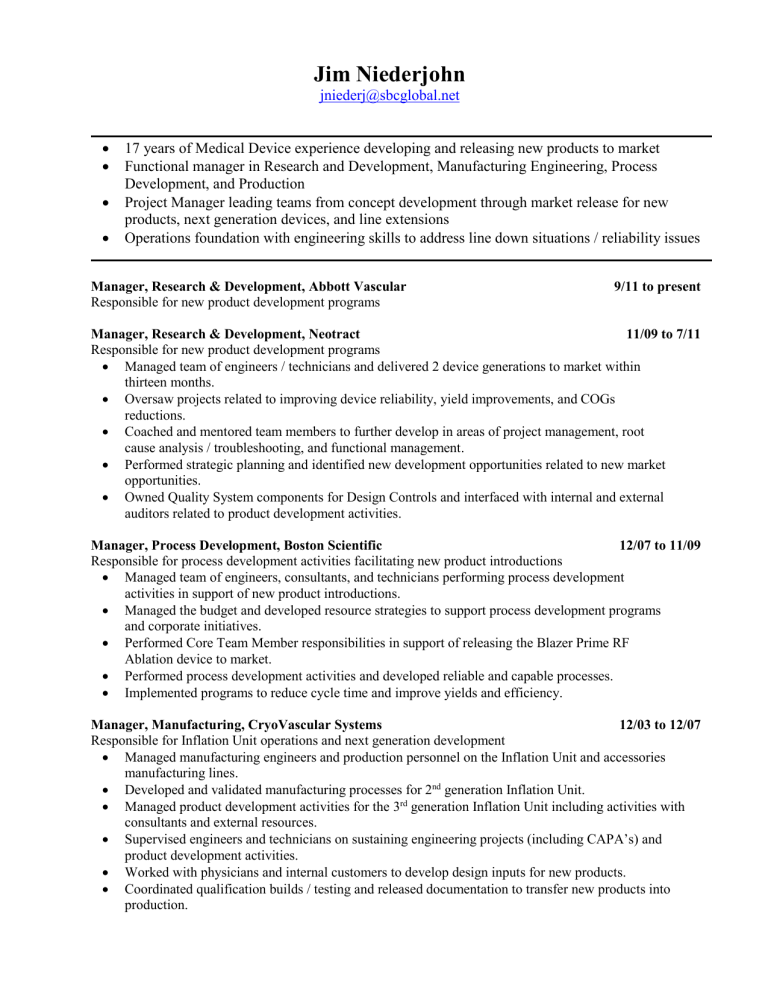

Professional Biography

Jim Niederjohn

jniederj@sbcglobal.net

17 years of Medical Device experience developing and releasing new products to market

Functional manager in Research and Development, Manufacturing Engineering, Process

Development, and Production

Project Manager leading teams from concept development through market release for new products, next generation devices, and line extensions

Operations foundation with engineering skills to address line down situations / reliability issues

Manager, Research & Development, Abbott Vascular

Responsible for new product development programs

9/11 to present

Manager, Research & Development, Neotract 11/09 to 7/11

Responsible for new product development programs

Managed team of engineers / technicians and delivered 2 device generations to market within thirteen months.

Oversaw projects related to improving device reliability, yield improvements, and COGs reductions.

Coached and mentored team members to further develop in areas of project management, root cause analysis / troubleshooting, and functional management.

Performed strategic planning and identified new development opportunities related to new market opportunities.

Owned Quality System components for Design Controls and interfaced with internal and external auditors related to product development activities.

Manager, Process Development, Boston Scientific 12/07 to 11/09

Responsible for process development activities facilitating new product introductions

Managed team of engineers, consultants, and technicians performing process development activities in support of new product introductions.

Managed the budget and developed resource strategies to support process development programs and corporate initiatives.

Performed Core Team Member responsibilities in support of releasing the Blazer Prime RF

Ablation device to market.

Performed process development activities and developed reliable and capable processes.

Implemented programs to reduce cycle time and improve yields and efficiency.

Manager, Manufacturing, CryoVascular Systems 12/03 to 12/07

Responsible for Inflation Unit operations and next generation development

Managed manufacturing engineers and production personnel on the Inflation Unit and accessories

manufacturing lines.

Developed and validated manufacturing processes for 2 nd generation Inflation Unit.

Managed product development activities for the 3 rd generation Inflation Unit including activities with consultants and external resources.

Supervised engineers and technicians on sustaining engineering projects (including CAPA’s) and product development activities.

Worked with physicians and internal customers to develop design inputs for new products.

Coordinated qualification builds / testing and released documentation to transfer new products into production.

Manager, Balloon Development, Creganna 5/03 to 12/03

Responsible for Balloon operations and development

Interfaced with customers to design balloons and develop manufacturing processes in order to meet their requirements.

Designed components / assemblies and performed product development activities as a team member on the internal catheter design teams.

Organized and directed the balloon blowing manufacturing production line.

Supported production by troubleshooting and resolving manufacturing issues.

Implemented systems to increase efficiency and reduce non-value added activities.

Manager, Research and Development, Guidant 6/01 to 4/03

Responsible for product development programs for Off Pump CABG Procedures

Performed project management responsibilities and directed activities for cross functional team members.

Developed and worked to aggressive schedules to meet key launch dates and released 4 new products in two years.

Provided functional management to R&D engineers and technicians.

Interfaced with surgeons to develop design inputs for new products and evaluated concepts and refined products in animal studies.

Manufacturing Engineer / Project Engineer, CardioThoracic Systems 3/97 to 6/01

Performed engineering / project management activities for new products introductions

Wrote protocols / reports and organized builds and testing for new product qualifications.

Worked with injection molding suppliers, extrusion suppliers, contract manufacturers, OEM suppliers, and other specialized suppliers to manufacture prototypes and production components.

Developed manufacturing processes including ultrasonic welding, thermal bonding, and adhesive bonding – cyanoacrylates and UV adhesives.

Designed manufacturing fixtures and equipment for production.

Conducted manufacturing engineering responsibilities including troubleshooting and resolving line down situations, balancing assembly line processes to improve throughput and efficiencies, and making design and process improvements to increase manufacturing yields.

Organized and worked with external shops to conduct biocompatibility testing, accelerated aging, packaging validation conditioning, and Sterilization Validations.

Advanced Manufacturing Engineer, Lam Research 2/96 to 3/97

Supported new product development programs and performed New Production Introduction activities

Created manufacturing documentation in support of building new products.

Supported builds and addressed manufacturing issues of new capital equipment tools.

Implemented cost reductions by making design changes and improving manufacturing processes.

Manufacturing Engineer, Siemens Medical Systems

Performed sustaining engineering responsibilities on the linear accelerator manufacturing line

Created and updated manufacturing documentation for products.

Performed troubleshooting of manufacturing issues on the production line.

Dispositioned non-conforming materials in support of MRB.

Performed supplier audits and worked with suppliers to address component issues.

Masters in Business Administration

Santa Clara University

Bachelor of Science Degree in Mechanical Engineering

California State University, Chico

6/94 to 2/96

2000

1994