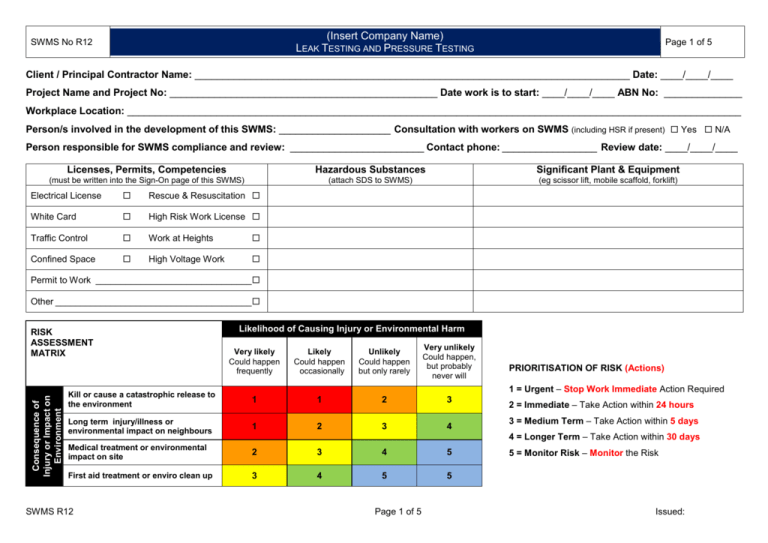

SWMS R12 Leak Testing And Pressure Testing

advertisement

(Insert Company Name) LEAK TESTING AND PRESSURE TESTING SWMS No R12 Page 1 of 5 Client / Principal Contractor Name: ______________________________________________________________________________ Date: ____/____/____ Project Name and Project No: ________________________________________________ Date work is to start: ____/____/____ ABN No: ______________ Workplace Location: ______________________________________________________________________________________________________________ Person/s involved in the development of this SWMS: ____________________ Consultation with workers on SWMS (including HSR if present) Yes N/A Person responsible for SWMS compliance and review: ________________________ Contact phone: _________________ Review date: ____/____/____ Licenses, Permits, Competencies Hazardous Substances Significant Plant & Equipment (must be written into the Sign-On page of this SWMS) (attach SDS to SWMS) (eg scissor lift, mobile scaffold, forklift) Electrical License Rescue & Resuscitation White Card High Risk Work License Traffic Control Work at Heights Confined Space High Voltage Work Permit to Work _______________________________ Other _______________________________________ Consequence of Injury or Impact on Environment RISK ASSESSMENT MATRIX Likelihood of Causing Injury or Environmental Harm Very likely Could happen frequently Likely Could happen occasionally Unlikely Could happen but only rarely Very unlikely Could happen, but probably never will Kill or cause a catastrophic release to the environment 1 1 2 3 Long term injury/illness or environmental impact on neighbours 1 2 3 4 Medical treatment or environmental impact on site 2 3 4 5 First aid treatment or enviro clean up 3 4 5 5 SWMS R12 PRIORITISATION OF RISK (Actions) 1 = Urgent – Stop Work Immediate Action Required 2 = Immediate – Take Action within 24 hours 3 = Medium Term – Take Action within 5 days 4 = Longer Term – Take Action within 30 days Page 1 of 5 5 = Monitor Risk – Monitor the Risk Issued: (Insert Company Name) LEAK TESTING AND PRESSURE TESTING SWMS No R12 Page 2 of 5 POTENTIAL SAFETY HAZARDS/RISKS WITH THIS TASK (tick relevant) LEGISLATION AND OTHER REFERENCES THE HARMONISED WHS REGULATION IS DESIGNATED BY: C = CHAPTER, P = PART, D = DIVISION, COP = CODE OF PRACTICE, HRCW = HIGH RISK CONSTRUCTION WORK (C6, P3, D2) Risk of Person Falling physical barriers, fall arrest, fall prevention, retrieval C4/P4 COP HRCW Temperature Extremes including Artificial sun, UV, freezers, boilers C3/P1 COP HRCW Energised Electrical Works live work, electric shock, testing, LOTO, UG services C4/P7 COP HRCW Asbestos likely exposure, register, PPE, airmonitoring Precast and Tilt Up Concrete lifting, moving, craning, placing, propping COP HRCW Demolition elect shock, isolations, LOTO, load bearing issues of structure C4/P6 COP HRCW Confined Space work in or near a confined space, unsafe oxygen level, competency, permit to work, spotter C4/P3 COP HRCW Flammable Atmosphere, Major Hazard Facility flammable gas, vapour, fumes, combustible dust, ignition sources, licenses, permits C3/P2/D8 C9 Schedules 15 - 18 HRCW Powered Mobile Plant, maintenance, competencies, traffic movement plan C5/P1/D7 HRCW Working in or near Water/Liquid risk of drowning, PFD, fall arrest Live Traffic Corridors working near/adjacent road, rail, traffic control, licenses C3/P1 HRCW Excavation >1.5 m deep engineers report, bench, batter, soil report, retrieval C8 COP HRCW C6/P3/D3 COP HRCW Pressurised Gas Distribution Mains or Piping hitting or puncturing & UG services C7/P1/D9 HRCW Refrigerant, Fuel or Chemical Lines flammable gas, vapour, fumes C3/P2/D8 HRCW Emergency/First-Aid/Remote Work first aid facilities, remote / isolated work, emergency response plan C3/P2 D3,4,6 COP Hazardous Subs/Chemicals/Lead SDS, registers, manifest, signage, spills, contamination, health monitoring, emergency planning C7, C8 Schedules 7 - 14 COP C3/P1 HRCW Falling Objects from above or on those below, lanyards, screens, drop zone C3/P2/D10 Work on Telecommunication Towers installing equipment, falls C3/P1 HRCW Alterations/Repairs/Temp Support to Prevent Collapse structural alterations, propping C3/P1 HRCW POTENTIAL ENVIRONMENTAL IMPACTS TO CONSIDER (tick relevant activities) Air pollution (dust) Contamination to ground Noise pollution (ambient) Soil erosion Contamination to water Hazards to flora & fauna Noise/Hearing Loss exposure, managing risk, PPE, audiometric testing and monitoring Other References: C4, P1 COP HEIRARCHY OF CONTROLS Most effective Eliminate Substitute Engineer Administration PPE Least effective SWMS R12 Page 2 of 5 Issued: (Insert Company Name) LEAK TESTING AND PRESSURE TESTING SWMS No R12 S T E P What are the Steps / Tasks Hazards at each Step Initial Risk Rating Control Description separate control/s are required for each hazard identified likelihood x consequence Page 3 of 5 Residual Risk Rating Persons Responsible for Controls likelihood x consequence 1 Entry to site Unknown site hazards and conditions 2 Site Induction / Familiarisation of site conditions 5 Supervisor & Workers 2 Never use oxygen to leak test, purge or pressure test a machine. Nitrogen is recommended for these purposes. Fire/explosion 3 Implement fire safety and first aid procedures according to the Safety Data Sheet (SDS) First aid available 5 Supervisor & Workers 3 Always use a gauge equipped regulator on the nitrogen cylinder and verify that the gauge has been recently checked and calibrated. Fire/explosion 3 Implement fire safety and first aid procedures according to the Safety Data Sheet (SDS) First aid available 5 Supervisor & Workers 4 When using nitrogen and a refrigerant trace for leak testing, always put the refrigerant first then valve off and remove the refrigerant cylinder before connecting and adding the regulated nitrogen. Fire/explosion 1 Implement fire safety and first aid procedures according to the Safety Data Sheet (SDS) First aid available 5 Supervisor & Workers 5 Never exceed the specified field leak test pressures. Check the instructions. Fire/explosion 2 Implement fire safety and first aid procedures according to the Safety Data Sheet (MSDS) First aid available 5 Supervisor & Workers 6 Do not allow the full cylinder pressure to enter a pressurising line. Ensure valve is off and disconnect the nitrogen cylinder when the recommended test pressure is attained. Fire/explosion 2 Implement fire safety and first aid procedures according to the Safety Data Sheet (SDS) First aid available 5 Supervisor & Workers 7 Do not pressure test any vessel at its design pressure (found on the equipment nameplate); Fire/explosion 2 Implement fire safety and first aid procedures according to the Safety Data Sheet (SDS) First aid available 5 Supervisor & Workers 8 Do not confuse water (brine) side test pressures with refrigerant side test pressures. 5 Supervisor & Workers SWMS R12 Fire/explosion 3 Implement fire safety and first aid procedures according to the Safety Data Sheet (SDS) First aid available Page 3 of 5 Issued: (Insert Company Name) LEAK TESTING AND PRESSURE TESTING SWMS No R12 9 Do not enter any vessel or restricted or closed space immediately after the use of significant amounts of nitrogen without procedure or testing oxygen levels. Asphyxiation Site specific tasks Site specific hazards 1 Page 4 of 5 Wear correct respirator PPE 6 5 Supervisor & Workers Site specific controls P P E other 1 2 3 4 5 6 7 8 9 10 11 12 13 (Mark all PPE required for this task – ensure available prior to commencing work) SWMS R12 Page 4 of 5 Issued: (Insert Company Name) LEAK TESTING AND PRESSURE TESTING SWMS No R12 Page 5 of 5 SWMS SIGN ON We, the undersigned, confirm that we have been consulted regarding the above SWMS and that its content is clearly understood. We also confirm that our required qualification/s to undertake this activity is current and that we are competent to complete the work safely and without risk to our own health or the health of others. We clearly understand that the controls in this SWMS must be applied as documented, otherwise work is to cease immediately and we will ensure that the work area is made safe should risks to other workers, visitors or the public remain. Worker’s Name Job Title Principal Qualification/License/Ticket Date Worker’s Signature I, the undersigned Supervisor confirm that I have checked all qualifications tendered and verify they are applicable and current. I have also ensured that all inductions have taken place and that all tools and equipment are properly maintained and safe to use. I have issued all relevant permits and have ensured to the best of my ability that the work area is safe and that the work will not damage any property or injure any persons. Person responsible for SWMS: ___________________________________________ SWMS R12 Page 5 of 5 Signature: _____________________________________________ Issued: