ME-603 Metal Cutting and CNC machines

advertisement

Gwalior Institute of Information

Technology

NOTES

ON

METAL CUTTING &

CNC MACHINES

[BE-603]

1

UNIT -1

[LATHE MACHINE]

Contents:

Classification of lathe Machines.

Engine lathe and their basic components.

Lathe specification.

Components & accessories.

Various operation on lathe machine.

Capstan and turret lathe machine.

Machining time

Single point cutting tool, tool geometry and nomenclature.

2

Lathe:- lathe is a machine which holds and rotate the work-piece between two rigid &

strong supports called live center and dead center.

Lathe machine is used to remove undesired material from a rotating work piece in the form of

chip.

Work piece

Live center

dead center

tool

fig-

Basic operation of lathe machine

Classification of lathe machine- According to production lathe can be classified in four

categories. These are discussed below1.

Low production type lathe machine

Bench lathe machine

Engine lathe machine

Tool room lathe machine

Speed lathe machine

2. Medium production type lathe machine

Turret lathes

(a) Ram type turret lathe

(b) Saddle type turret lathe

Capstan lathe

3. High production type lathe machine

Automatic lathe machine

3

4. Special purpose lathe machine

Gap lathe machine

Duplicating lathe machine

Crank shaft lathe machine

Wheel lathe machine

Flow turning lathe machine

Bench lathe: It is a very small lathe mounted on separately

prepared bench or cabinet and used for small, precision works.

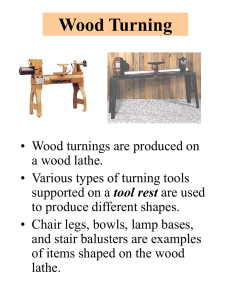

Speed lathe: They do not have provision for power feed and have no gear box, carriage,

lead screw etc. Two or three spindle speeds are available by cone pulley arrangement. They

are used for wood turning, polishing, metal

spinning etc.

Engine lathe: In olden days lathe was driven by a steam engine. Hence the name is still in

existence even after modern lathes are provided with motor drive.

Tool Room Lathe: It is nothing but the engine lathe equipped with some extra attachments

for accurate and precision work like taper turning attachment, follower rest, collets, chucks

etc. The bed is relatively small.

Capstan & Turret lathes: These are semi automatic type machines very useful for mass

production (small lot sizes). Less skill is required for operator and wide range of operations

can be performed. They carry special mechanisms for indexing their tool heads. They are

provided with a front tool post which can hold 4 turning related tools and rear tool post which

can hold 2 to 4 turning related tools. The turrets can hold only drilling related tools. The

turning tools used in the rear tool post are reverse tools with reverse geometry.

Fig- turret lathe

4

Fig- Capstan lathe

Automatic lathes: These are designed so that all the working and Job handling movements

of the complete Manufacturing process for a job are done automatically. No participation of

the operator is required during the operation. They fall in the category of heavy duty, high

speed lathes employed in mass production (large lot sizes). Geneva mechanism is used for

indexing the turret.

The general purpose single spindle automatic lathes are widely used for quantity or mass

production (by machining) of high quality fasteners; bolts, screws, studs etc., bushings, pins,

shafts, rollers, handles and similar small metallic parts from long bars or tubes of regular

section and also often from separate small blanks.

5

Special – purpose lathes: These are designed to perform certain specified operations only.

Eg: Facing lathe, vertical lathe, crank shaft lathe.

Working and Construction of a center lathe or engine lathe

machine-

A lathe machine is used for the shaping and machining of various work pieces.

There are many different types depending on the material you are working on.

Fig-engine lathe machine

Various parts or components of engine lathe Bed

6

Head stock

Tail stock

Spindle

Carriage

Saddle

Cross-slide

Compound rest

Tool post

Apron

Live center

Dead center

Lead screw

Feed rod

Sleeve

Hand wheel

Bed- The bed is the foundation or base of the lathe. It holds or supports all other parts. The

top of the bed is planed to from guides or ways.

Headstock- The head stock is permanently fixed to the left hand end of lathe machine. Its

function is to support the first operative unit of the lathe machine, i.e. the spindle. the spindle

revolves in bearings one at each end of the headstock. The spindle is rotated by a

combination of gear and cone pulleys or by gears alone.

Tailstock- The tailstock is situated at the right hand end of the bed. It is used for supporting

the work when turning on centers or when a long component is to be held in a chuck. It is

also used for holding and feeding the tools such as drills, reamers, taps etc.

Carriage- The carriage controls and supports the cutting tool. It is movable on the bed ways

and its purpose is to hold the cutting tool and to impart to it either longitudinal or cross-feed.

Saddle- It is a H- shaped casting that fits over the bed and slides along the ways between

the headstock and tailstock.

Cross-slide- It is mounted on the saddle. It provides cutting tool motion which is

perpendicular to the lathe itself.

Compound Rest- It is mounted on the top of the cross- slide. The compound rest has a

graduated base and can be swivelled around a vertical axis.

7

Tool Post- it is mounted above the compound rest. A t-slot is machined in the compound

rest to accommodate the tool post. It is used to hold the tool also.

Apron- It is fastened to the saddle and hangs over the front of bed. It contains gears,

clutches and levers for operating the carriage by hand or power feed.

Difference between Turret or Capstan lathe-

Turret lathe M/c

Capstan lathe M/c

Turret head (square (or)

1. hexagonal) is mounted on saddle.

Turret head (round (or) square

1. (or) hexagonal) is mounted on

auxiliary slide that moves on

guide ways provided on saddle.

Less rigidity, vibrations occur,

hence suitable for lighter and

2. smaller jobs (up to 60mm) and

precision work

The above arrangement gives

rigidity as forces are transferred to bed.

2. Hence capable of handling heavy

jobs (up to 200mm) and

severe cutting conditions

Tool travel is along entire bed

3. Length.

Tool travel is limited because of

3. auxiliary slide traverse limitation.

Tool feeding is slow and

4. causes fatigue to operator

hands.

5. No tail stock

Tool feeding is fast and causes

4. less fatigue to operator hands.

5. No tail stock

Specification of lathe machine1)

2)

3)

4)

5)

6)

7)

Height of centers over bed,

Maximum swing over bed ,

Maximum swing over carriage,

Maximum swing over Gap,

Maximum distance b/w centers,

Length of bed,

Number of speeds and feeds etc.

8

Work holding devices

1) Chucks-A chuck is a specialized type of clamp used to hold an object, usually an

object with radial symmetry especially a cylindrical object. It is most commonly used

to hold a rotating tool (such as the drill bit in a power tool ) or a rotating work piece

(such as the bar or blank in the headstock spindle of a lathe ).

(A) 3 Jaw–Self centering, smaller in size , used for round cross sections.

(B) 4 Jaw –Not self centering, medium in size, used for round, square, rectangular

cross sections.

(C) Collets- Fixed sizes. They are air operated or hand operated. Used in- tool room

lathes, bar automatic lathes, vertical milling machines to hold end mills.

(D) Pneumatic Chucks –In chucking Automatics Note In bar automatics the

component is parted of from the bar and in chucking automatics ,the component is

released from the chuck and another blank is loaded from the magazine.

(E) Magnetic- Used for ferrous metals in Lathe , Milling ,Surface Grinding machines

for light works and also where Distortion is not permitted like in aerospace

components.

(F) Vacuum- Similar to above and used for non ferrous metals.

2) Face plate- Used for large size work pieces of round, square, rectangular, and also

very complex geometries not possible in any other devices.

3) Carriers and catch plates- Used for supporting shafts, mandrels for imparting

rotation.

4) Centers- They are used for supporting purpose.

a) Live centre – used with face plate

b) Dead centre – used in tail stock

5) Mandrel- Used to support the work pieces and also for holding hollow parts to meet

concentricity requirements.

6) Steady rest – mounted on bed, used for long heavy jobs that deflect centrally by self

weight.

7) Follower rest – mounted on carriage and moves with tool, used for long thin jobs

that deflect laterally by cutting force.

9

Operations which can be performed on a lathe either by holding the work piece

between the centres or by a chuck area)

b)

c)

d)

e)

f)

g)

h)

i)

Thread cutting

Taper turning

Chamfering

Facing

Forming

Knurling

Straight turning

Shoulder turning

Eccentric turning

Thread cutting- The principle of single-point thread cutting is the feed movement of the

tool in relation to the work piece rotation. The point generates the typical spiral groove that

makes up the screw thread with a certain pitch. Basically, threading is a well-coordinated

turning operation with a form-tool. During the feed passes, the tool is moved longitudinally

along the work piece and then withdrawn and moved back to the starting position for the next

pass along the same thread groove.

Taper Turning- When the diameter of a piece changes uniformly, from one end to the

other, the piece is said to be tapered. Taper turning as a machining operation is the gradual

reduction in diameter from one part of a cylindrical work piece to another part. Tapers can be

either external or internal. If a work piece is tapered on the outside, it has an external taper; if

it is tapered on the inside, it has an internal taper.

10

Fig- Taper Turning

Chamfering- Chamfering removes the burrs and sharp edges, and thus makes the handling

safe. Chamfering can be done by a form tool having angle equal to chamfer which is

generally kept at 45°.

Fig- Chamfering

Facing- The facing is a machining operation by which the end surface of the work piece is

made flat by removing metal from it.

Fig- Facing of workpiece

Knurling- Knurling is a process of impressing a diamond shaped or straight line pattern into

the surface of a work piece by using specially shaped hardened metal wheels to improve its

appearance and to provide a better gripping surface.

11

Straight Turning- Straight turning is the operation of removing excess amount of material

from the surface of a cylindrical job.

Fig- Straight turning

Operations which can be performed by holding the work by a chuck or a face

plate or an angle plate area)

b)

c)

d)

e)

f)

Drilling

Reaming

Boring

Tapping

Under cutting

Taper Boring

Drilling- Drilling is a cutting process that uses a drill bit to cut or enlarge a hole of circular crosssection in solid materials. The drill bit is a rotary cutting tool, often multipoint.

12

Reaming- Reamers are used to finish drilled holes or bores quickly and accurately to a

specified diameter.

Boring- Boring is the enlarging and truing of a hole by removing material from internal

surfaces with a single-point cutter bit in the lathe machine.

Tapping-The lathe can be used as a device to hold and align a tap or hand die to cut internal

or external threads quickly for threads that do not require a high degree of accuracy or a fine

finish.

Operations which can be performed by using special attachments area) Grinding

b) Milling

13

Taper Turing-

Taper turning means, to produce a conical surface by gradual reduction

or increase in diameter from a cylindrical work piece. This tapering operation has wide range

of use in construction of machines. Almost all machine spindles have taper holes which

receive taper shank of various tools and work holding devices.

Taper Turning Methods- A taper may be turned by any one of the following methods:

By a broad nose form tool.

By setting over the tailstock centre.

By swivelling the compound rest.

By a taper turning attachment.

By combining longitudinal and cross feed in a special lathe.

Taper Turning by a Form Tool- A broad nose tool having straight cutting edge (form

tool) is set on to the work at half taper angle, and is fed straight into the work to generate a

tapered surface. In this method the tool angle should be properly checked before use. This

method is limited to turn short length of taper only. Tool will require excessive cutting

pressure, which may distort the work due to vibration and spoil the work surface.

Taper Turning by Setting over the Tailstock- The principle of turning taper by this

method is to shift the axis of rotation of the work piece, at an angle to the lathe axis, and

feeding the tool parallel to the lathe axis. The angle at which the axis of rotation of the work

piece is shifted is equal to half the angle of the taper. The body of the tailstock is made to

slide on its base towards or away from the operator by a set over screw. The amount of set

over being limited, this method is suitable for turning small taper on long jobs. The main

disadvantage of this method is that the live and dead centres are not equally stressed and the

wear is not uniform. Moreover, the lathe carrier being set at an angle, the angular velocity of

the work is not constant.

(D= Large Diameter of Taper, d= Small Diameter of Taper, L=Length of work,

l= Length of taper, α= Half taper angle, S = Set over)

Taper Turning by Swivelling the Compound Rest-This method employs the principle

of turning taper by rotating the work piece on the lathe axis and feeding the tool at an angle to

the axis of rotation of the work piece. The tool mounted on the compound rest is attached to a

circular base, graduated in degree, which may be swivelled and clamped at any desired angle.

Once the compound rest is set at the desired half taper angle, rotation of the compound slide

screw will cause the tool to be fedat that angle and generate acorresponding taper. This

method is limited to turning a short taper owing to the limited movement of the cross slide.

But a small taper may also be turned. The compound rest may be swivelled at 45°on either

side of the lathe axis enabling it to turn a steep taper. The movement of the tool in this

method is being purely controlled by hand, thus giving a low production capacity and poor

surface finish. The setting of the compound rest is done by swivelling the rest at half taper

angle, if this is already known. If the diameter of the small and large end and Length of taper

are known, the half taper angle can be calculated from the equation {Tan α = (D-d) / 2L}.

14

Taper Turning by a Taper Attachment- The principle of turning taper by a taper

attachment is to guide the tool in a straight path set at an angle to the axis of rotation of the

work piece. A taper turning attachment consists essentially of a bracket or frame which is

attached to the rear end of the lathe bed and supports a guide plate pivoted at the centre. The

plate having graduations in degrees may be swivelled on either side of the zero graduation

and is set at the desired angle with the lathe axis. When the taper turning attachment is used,

the cross slide is first made free from the lead screw by removing the binder screw. The rear

end of the cross slide is then tightened with the guide block by means of a bolt. When the

longitudinal feed is engaged, the tool mounted on the cross slide will follow the angular path,

as the guide block will slide on the guide plate set at an angle to the lathe axis. The required

depth of cut is given by the compound slide which is placed at right angles to the lathe axis.

The guide plate must be set at half taper angle and the taper on the work must be converted in

degrees. The maximum angle through which the guide plate may be swivelled is100 to12°on

either side of the centre line. If the Large diameter (D), Small diameter (d), and the taper

length (L) are specified, the angle of swivelling the guide plate can be determined from

equation. Tan ά = (D-d) / 2L.

Taper Turning by Combining Feeds - Taper turning by combining feeds is a more

specialized method of turning taper. In certain lathes both longitudinal and cross feeds may

be engaged simultaneously causing the tool to follow a diagonal path. This is the resultant of

the magnitudes of the two feeds. The direction of the resultant may be changed by varying

the rate of feeds by change gears provided inside the apron.

Single point cutting tool- A single point cutting tool consists of a sharpened cutting

part and the shank and main parts or elements which are:

1: Shank- It is the main body of the tool.

2: Flank- The surface or surfaces below the adjacent to the cutting edge is called flank of the

tool.

3: Face- The surface on which the chip slides is called the face of the tool.

4: Heel - It is the intersection of the flank and the base of the tool.

5: Nose- It is the point where the side cutting edge and end cutting edge intersect.

6: Cutting Edge -It is the edge on the face of the tool which removes the material from the

work piece. The cutting edge consists of the side cutting edge (major cutting edge) and

cutting edge (minor cutting edge) and the nose.

7: Nose radius- Side and end cutting edges can be joined to form a point but that is not

desirable as it leads to high heat concentration at a sharp point. Joining side and end cutting

edges by an arc called as nose radius.

15

Fig- Tool geometry

16

Various angles in tool geometry1) Side Cutting Edge Angle- The angle between side cutting edge and the side of the

tool shank is called side cutting edge angle. It is often referred to as the lead angle.

2) End Cutting Edge Angle- The angle between the end cutting edge and a line

perpendicular to the shank of the tool shank is called end cutting edge angle.

3) Side Relief Angle- The angle between the portion of the side flank immediately

below the side cutting edge and a line perpendicular to the base of the tool.

4) End Relief Angle- The angle between the end flank and the line perpendicular to

the base of the tool is called end relief angle.

5) Back Rake Angle- The angle between the face of the tool and line perpendicular to

the base of the tool measures on perpendicular plane through the side cutting edge. It

is the angle which measures the slope of the face of the tool from the nose, towards

the rack. If the slope is downward the nose it is negative back rake.

6) Side Rake Angle- The angle between the face of the tool and a line parallel to the

base of the tool measured on plane perpendicular to the base and the side edge. It is

the angle that measure the slope of the tool face from the cutting edge, if the slope is

towards the cutting edge it is negative side rake angle and if the slope is away from

the cutting edge, it is positive side rake angle. If there is no slope the side rake angle is

zero.

7) Lip angle- its is the angle between the tool face and flank of the tool.

17

Machining time

-Machining time is the time when a machine is actually processing

something. Generally, machining time is the term used when there is a reduction in material

or removing some undesirable parts of a material. For example, in a drill press, machining

time is when the cutting edge is actually moving forward and making a hole. Machine time is

used in other situations, such as when a machine installs screws in a case automatically. is the

time when a machine is actually processing something.

Generally, machining time is the term used when there is a reduction in material or removing

some undesirable parts of a material. For example, in a drill press, machining time is when

the cutting edge is actually moving forward and making a hole. Machine time is used in other

situations, such as when a machine installs screws in a case automatically.

Machining time (T) can be calculated by the equation:

T = L/ N*F

where;

is turning length in mm

is the feed (mm/rev)

is the rotational speed

18