Vertical Turret Lathe - CVSR College of Engineering

advertisement

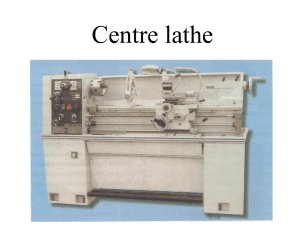

Lathe Machines Types of Lathes: • Center Lathe • Engine Lathe • Bench Lathe • Capstan & Turret Lathes • Automatic Lathes • Multi Spindle Lathes • Vertical Turret Lathes • CNC Lathes Kinematic Scheme of Lathe Machine Speed Gear Box Tool Post Headstock Saddle Chuck Tail Stock Feed rod Feed Gear Box Lathe Bed Half Nut Apron Carriage Lead Screw Lathe Machine – Pulley driven (Light Duty) Lathe – All Geared High Speed Precision Lathe – All geared (X- Y Movements) The machining operations generally carried out in centre lathes are : • Facing • Centering • Rough and finish turning • Chamfering, shouldering, grooving, recessing etc • Axial drilling and reaming by holding the cutting tool in the tailstock barrel • Taper turning by offsetting the tailstock swivelling the compound slide using form tool with taper over short length using taper turning attachment if available combining longitudinal feed and cross feed, if feasible. • Boring (internal turning); straight and taper • Forming; external and internal • Cutting helical threads; external and internal • Parting off • Knurling A – Turret Locking Handle, B – Turret, C - Capstan Slide, E - Capstan Slide Block, D - Capstan Rest, F - Sliding Bridge The capstan lathe, having a relatively short stroke of the tool head and automatic indexing, results in a rapid presentation of the tools to the work. The turret lathe, on the other hand, is suitable for long and heavy work, the larger size of machines having a capacity for bar work up to 200 mm diameter X 1500 mm long or for chuck work up to 750 mm diameter. Capstan lathes are limited to a maximum of 300 mm diameter chuck works. It is clear that turret lathes are larger, in size as compared to capstan lathes. Unlike capstans, the turret and dead stops on turret lathes have to be indexed into position by hand. Capstan and turret lathes give quite effectively the normal accuracy required for interchangeable mass production. The dimensional accuracy may be within 0.002 mm for turning and boring and within 0.005 mm for reaming. A – Headstock, B – Spindle, C - Pilot Bar, D – Tool post, E - Rear Tool post, F - Cross slide, G - Intermediate saddle, H – Turret, I - Turret Clamp Lever, J - Saddle Looking Lever, K - Star Handle for Turret Operation, L - Turret Apron, M - Turret saddle, N - Intermediate saddle Apron, O - Feed Gearbox Mini Turret Lathe Mini Capstan Lathe Mini Capstan Lathe Specs: Max. Collet Cap (Round): mm 25 32 32 42 Spindle Bore dia: mm 32 38 40 50 No.& Range of Speeds: RPM 3/ 650 to 1600, 3/ 650 to 1600 4/560 to 1600, 4/560 to 1600 Length of Bed: mm 980 980 1210 1210 Max. Dist. Between Spindle -to Turret Face: mm 275 275 400 400 Effective Travel of Capstan Slide: mm 95 95 130 130 Power Required: HP 2 2 2 3 Vertical Turret Lathe – CNC 16’ dia Vertical Turret Lathe – 88” Dia Table (2 Turret heads) Vertical Turret Lathe – CNC 46” dia Multi Spindle Lathe – 6 Spindles Shimada Machinery Co. Ltd, www.smd.co.jp • The 6-Spindle Automatic Lathe uses one spindle for loading and unloading. • The other five spindles are used for turning • The Multi-Spindle Automatic Lathe moves work pieces between 6 or 8 stations (processing locations), with processes such as boring, turning, chamfering, screw cutting, grooving, and drilling conducted at separate stations. •Pos1 loading/unloading requires the most time. This longest position time becomes the cycle time when using a 6 or 8 spindle automatic lathe