here

advertisement

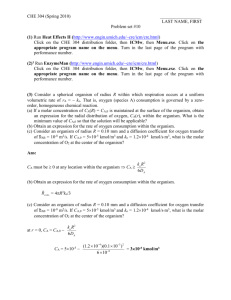

CHE 304 (Spring 2010) __________________ LAST NAME, FIRST Problem set #2 (1) 1 For a first-order reaction, the following rate coefficients were found: Temperature, °C 38.5 53.1 77.9 k, h-1 0.044 0.301 1.665 Determine the activation energy of the reaction in kJ/mol. (2)2 There are two reactors of equal volume available for your use: one a CSTR, the other a PFR. The reaction is second order ( rA = kCA2 = kCA02(1 X)2), irreversible, and is carried out isothermally AB There are three ways you can arrange your system: (a) Reactors in series: CSTR followed by PFR (b) Reactors in series: PFR followed by CSTR (c) Reactors in parallel with half the feed rate going to each reactor after which the exit streams are mixed. (d) State which system will give the highest overall conversion and which system will give the lowest overall conversion. Note: Rearrange the mass balance equation to the form that contains the term FA0 . Let VkC A2 0 FA0 = 1 and solve for the fractional conversion. VkC A2 0 1 2 G.F. Froment, K.B. Bischoff, J. De Wilde, Chemical Reactor Analysis and Design, Prentice Hall, 2010 Fogler, H. S., Elements of Chemical Reaction Engineering, Prentice Hall, 1999 (3)1 The exothermic reaction AB+C was carried out adiabatically and the following data recorded: X rA mol/Lmin 0 10 0.2 16.67 0.4 50 0.5 50 0.6 50 0.8 12.5 0.9 9.09 The entering molar flow rate of A was 300 mol/min. (a) (b) (c) (d) (e) (f) What are the PFR and CSTR volumes necessary to achieve 40% conversion? Over what range of conversions would the CSTR and PFR reactor volumes be identical? What conversion can be achieved in a 10.5 L CSTR? What conversion can be achieved if a 7.2 L PFR is followed in series by a 2.4 L CSTR? What conversion can be achieved if a 2.4 L CSTRR is followed in series by a 7.2 L PFR? Plot the conversion and rate of reaction as a function of PFR reactor volume up to a volume of 10 L. (4)3 Consider an ideal batch reactor with the irreversible homogeneous reaction A + 2B 3C + D This liquid phase reaction has the rate equation − rA = kCA2CB CD-1 The reaction rate constant is k = 1.5 L/mol∙hr at 350oK. The activation energy of the reaction is 100 kJ/mol. The initial concentrations are: CA0 = 2.0 mol/L, CB0 = 4.0 mol/L, CC0 = 0 mol/L, and CD0 = 1.0 mol/L. We will neglect any reaction that takes place while the initial charge is being added to the reactor, and while the reactor and contents are being heated to reaction temperature. (a) How much time is required for the concentration of A to reach 0.10 mol/L if the reactor run isothermally at 350oK? What is the concentration of C at this time? (b) The reactor will be run isothermally at 350oK. The concentration of A in the final product must be less than 0.20 mol/L, and the molecular weight of C is 125. An average of 10 hours is required between the batches in order to empty and clean the reactor, and prepare for the next batch. How large must the reactor be in order to produce 200,000 kg of C annually (with 8000 hours per year of operation)? (c) We want to produce 200,000 kg of C annually, with a final concentration of A of 0.20 mol/L or less. The only reactor available has a working volume of 1400 L. At what temperature does the reactor have to be operated, if it is operated isothermally? Once again, an average of 10 hours is required between batches to empty and clean the reactor, and to prepare for the next batch. 3 Roberts, G. W., Chemical Reactions and Chemical Reactors, Wiley, 2006 (5) The elementary gas-phase reaction3 (CH3)3COOH(CH3)3 C2H6 + 2CH3COCH3 is carried out isothermally in a flow reactor with no pressure drop. The specific reaction rate at 50oC is 10-4 min-1 and the activation energy is 85 kJ/mol. Pure di-tert-butyl peroxide enters the reactor at 10 atm and 127oC and a molar flow rate of 4.0 mol/min. Calculate the reactor volume to achieve 90% conversion in a CSTR and a PFR. If this reaction is to be carried out at 10 atm and 127oC in a batch mode with 95% conversion, what reactor size would be required to process (2.5 mol/min 60 min/h 24 h/day) 3600 mol of di-tert-butyl peroxide per day? You can assume a downtime of 6 hr between batches for cleaning and feed preparation. Assume that the reaction is reversible with equilibrium constant KC = 0.025 mol2/L6 and calculate the equilibrium conversion and then repeat the calculation for the CSTR and the PFR to achieve 95% of the equilibrium conversion. (6)4 Equilibrium with respect to the reaction A(g) + B(g) = C(g) will be studied by measuring the volume change accompany the reaction. The temperature and pressure are held constant and the initial volume and the final volume of the reacting system are recorded. Three tested were made and are summarized in the table. Has equilibrium been established? If so what is the value of K? P(mmHg) 500 600 600 yA 0.5 0.333 0 Initial composition yB yC 0.5 0 0.667 0 0 1.0 Volume (cm3) Initial Final 200 150 300 233 200 293 (7) Run Murder Mystery (http://www.engin.umich.edu/~cre/icm/cre.html) Click on the CHE 304 distribution folder, then copy the Heat1 Murder folder to your flash drive or H:\ drive. Open this folder and click on the appropriate program name (Murder Mystery.exe). Turn in the last page of the program with performance number. 3 4 Fogler, H. S., Elements of Chemical Reaction Engineering, Prentice Hall Kyle, B.G., Chemical and Process Thermodynamics, Prentice Hall, 1999