EIT 233 1002 - Great Basin College

advertisement

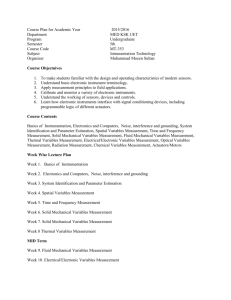

Great Basin College Introduction to Instrumentation Student Syllabus for EIT 233, section 1002 (4 Credits) Location & Time Room: GDCIT 202 Time: 08/31/2015-09/24/2015 M, Tu, W, Th 12:30-4:30 pm Instructor Information: Name: Dr. Rod Sidwell Office: DCIT Room 257 Hours: M, T, W, Th 10:00 – 11:00 a.m. by appointment, After class every day 4:30-5:00 p.m. no appointment. E-mail: rod.sidwell@gbcnv.edu Phone: Office: 775-753-2181 Fax: 753-7534 Home: 775-624-4446 Required Texts: Instrumentation and Process Control, 6th edition Instrumentation and Process Control Workbook, 6th edition Purdy’s Instrument Handbook Prerequisites: None This course is essential and a prerequisite for other instrumentation courses offered by GBC. Learning Outcomes: Successful completion of this course will provide the student with an understanding of the concepts of instrumentation as used in industry and why the accompanying skills are an exciting and highly sought after trade. Common pneumatic and electronic instruments that are used to control processes in refineries, power plants, mines, and most manufacturing facilities, will be discussed. Examples of temperature, pressure, level and flow measurement and control are developed. An important aspect of these objectives is to develop and improve the understanding of underlying physical phenomena used by measurement and control instrumentation. Students will use Excel to carry-out homework calculations. Use of Excel will be covered in lab. This course consists of lecture, class discussion, lab demonstrations, and lab exercises. Students will gain knowledge in the following: EIT 233 Introduction to Instrumentation 1 1. Recognize how and why measuring instruments play an important role in the control of industrial and manufacturing processes. 2. Have the ability to carry out basic calculations related to instrumentation. 3. Instrumentation theory and instruments as related to: Pressure Level Temperature Flow 4. Understand basic feedback control loops used in industrial processes. Measurements for learning outcomes: Success in the course will be demonstrated by the ability to: 5. Recognize how and why measuring instruments play an important role in the control of industrial and manufacturing processes. 6. Demonstrate an understanding of the physical processes: flow, level, pressure, and temperature. 7. Understand basic feedback control loops used in industrial processes. Approach (Method to achieve learning outcome): Reading and in class review of textbook materials Completion of workbook exercises Completion of supplemental exercises and material provided by instructor. Work in the computer laboratory and downstairs instrument lab Review of homework and quiz solutions Test preparation (Quizzes and a final exam are used to evaluate progress) Schedule: A detailed schedule is available on Canvas and is subject to modification. Instrument labs for EIT 233 1. Temperature measurement using thermometer, RTD and Thermistors. 2. Vapor pressure demonstrations and quiz, into to Dalton’s law of partial pressures, Ideal gas. Archimedes principle density measurement. 3. Excel 1 – computer lab hands on training, build multiplication table, learn about $, how to perform basic calculations. 4. Excel 2 – Use the data from lab 1 to create graph and plot. Develop a formula that describes thermistor response to temperature changes. 5. Use thermowell calibrators in the lab, also build a thermocouple using extension grade wire, solder. Test the TC and report the result. 6. Turn light on and off using HMI, discuss relays and SSR’s 7. Pressure measurement and calibration of gauges with deadweight test 8. HART introduction 9. Hart with 789 and transmitters, calibrate a temperature transmitter, calibrate a pressure transmitter 10. Introduction to sensor element and nonlinear sensor response, Sharp distance sensor 11. Distance measurement project. Construct distance measurement system, calibrate and 12. Written report due and analysis for distance measurement sensor project. EIT 233 Introduction to Instrumentation 2 13. 14. 15. 16. Intro to PID controllers, UDC 3300 and start of “flashing-lamp” project. Develop wiring diagram for PID controller, SSR and load. Once approved build the circuit. Tune PID controllers, UDC 3300 for level control and temperature control of lamp. Turn in written report due on PID temperature control. Evaluation and Grades: Grade A B C D F 90-100% 80-89% 70-79% 60-69% less than 60% Weight of Activities: 1) Tests and quizzes 2) Lab activities 3) Homework 4) Final 5) Weekly progress report 25% 45% 15% 15% required 1) Tests and Quizzes: Graded test will be given covering each major topics. A total of four equally weighted tests are to be given (may vary at instructors discretion). 2) Homework and Lab: Doing the homework is important and central to understanding the material. Late work may be accepted by prior arrangement. Homework assignments are stated in class schedule (subject to change). Generally, homework assignments will be due at the end of each week. Completion of laboratory activities and participation may be included as part of the homework grade at the instructors discretion. The homework is your chance to make mistakes without it costing you too much, which is why it is only 15% of the grade. I strongly encourage active participation on the homework as it is key to successful completion of the class. Much of the lab grade rest on two written reports that represent nearly half of the lab activities. These reports teach students concise and accurate reporting of measurements, findings, and calibration, as expected in industry. 3) Progress Report: Each week, each student will prepare a short (one paragraph, no more than 50-100 word), concise, coherent written statement of what he or she learned this week. Don’t try to cover everything. It could discuss important topics, things that were especially interesting, useful, difficult or confusing. It could discuss how a specific measurement could be applied in a plant. EIT 233 Introduction to Instrumentation 3 Why is this report being assigned? Communication skills are essential in the workplace. Many positions will require reports on work carried out. Clear reliable communication with your boss will aid your career. It forces reflection on the weeks work and aids learning. Trains the student to give short, concise, articulate answers. This feedback will improve the quality of the class. What you say and how you say it is important. The instructor will read each report. There is no right or wrong answer, per se. The progress reports are required, but not graded. Failure to provide a progress reports will result in a reduced homework/lab grade. 4) Attendance and Student Responsibility: In this course as in the workplace, students must attend class and turn in assignments on time. Attendance will be taken daily and will count towards final grade. All assignments must meet deadlines (no late assignments). Missing class: A considerable amount of material is covered during each class. Missing class will cause the student to fall behind. Absenteeism and tardiness will reflect on the final grade. Tardiness will count as one-half of an absence. Each absence will reduce the final grade by 3%. It is the student’s responsibility to keep up with the material and submit assignments on time. If a class must be missed because of an emergency, students must notify the instructor in advance when possible. Other: Each class is four hours in length. Students will be given periodic breaks. Cell phones should be turned off. If you need to make a call, do so outside the classroom during a break. No texting in class. Water and drinks are allowed in class. In general, students may quietly leave class and return to get a drink of water, attend to biological needs, etc. Students are expected to abide by the student code of conduct found at GBC website. Fighting, threatening peers, rude language, and cheating will NOT be tolerated in this class and you will be withdrawn from the class if you behave in this manner. Student Conduct Statements Academic Honesty Statement Great Basin College considers academic honesty one of its highest values. A student who obtains academic credit for work that is not the product of his or her own effort is being dishonest and undermining the academic integrity of the college. Students are expected to be the sole authors of their work. Use of another’s ideas must be accompanied by specific citation and reference. In addition, a learner may not submit the same work for credit in more than one course. The disciplinary consequences of plagiarism and other forms of academic dishonesty include non-acceptance of work EIT 233 Introduction to Instrumentation 4 submitted, a failing grade in the course, and/or other disciplinary action as outlined in Great Basin College’s Student Conduct Policy. Safety: All students participating in laboratory activities at school or on site will be required to review and sign GBC Electrical Technology Safety Procedures. No student use of laboratory or tools will be allowed unless authorized supervision is present or special permission has been granted by the instructor. Safety glasses and closed toed shoes are required in the lab at all times even if work is only at Engineering Work Stations. Disability Statement Great Basin College is committed to providing equal educational opportunities to qualified students with disabilities in accordance with state and federal laws and regulations, including the Americans with Disabilities Act of 1990 and Section 504 of the Rehabilitation Act of 1973. A qualified student must furnish current verification of disability. The Students with Disabilities Office, located in Berg Hall. Will assist qualified students with disabilities in securing the appropriate and reasonable accomidations, auxiliary aids, and services. For more information or further assistance, please call 775753-2271. EIT 233 Introduction to Instrumentation 5