Validation Data

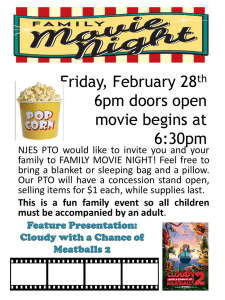

advertisement

This subset of data that will ultimately be collected from industry projects funded by DOE includes: numerical models and predictions, device specifications, and validation data obtained under the DOE award. Cost and Time Estimates Provide a time and cost estimate for the tank tests that were completed. Numerical Models and Performance Predictions Please provide numerical models which were used to model the subscale physical model that was tank tested under the award. Include description of approach and modeling tools, equations of motion, input and output files, power predictions, power curves, etc. Validation Data Facility Information Facility and Logistics Information Type Dimensions Beach and reflection characteristics Calibration data Wave maker specifications and calibration Details E.g. Basin or Flume Length, width, depth, etc. - Sample Rate A minimum data sample rate of 100 samples per wave period (T) should be used for all measurements. In some cases a higher data sample rate may be required and the required sample rate should be determined on a case-by-case basis. Time Synchronization It is very important that all data gathered is time synchronized. If measurements are not in sync, comparing numerical and experimental data is possible in the frequency domain, but problematic in the time domain. Frequency domain validation is less robust than time domain validation. Wave Measurement Requirements The waves that are generated determine the hydrodynamic forces on the device. WEC devices are generally tested in regular and irregular waves and both types of waves must be accurately characterized. At minimum, a single wave gauge upstream and downstream of the device is required. Wave measurements Height Period Details Time resolved Time resolved Water depth Directional wave spectra Water current velocity Wave orbital velocity Wave propagation direction For irregular waves If applicable If available With respect to the device orientation Video Monitoring If possible, tests should be video recorded. Body Motions and Forces Body Motions and Forces 6 degree-of-freedom motion Initial condition Wave pressure force Accelerometers Tilt sensors or rate sensors Relative position measurement (if applicable) Details Time resolved surge, sway, heave, roll, pitch, yaw and derivatives Device location with respect to other devices, device heading, etc. On submerged parts of bodies Time resolved accelerations of each body Time resolved rate of rotation of each body Time resolved potentiometer readings PTO System Performance PTO System Performance Forces and torques Velocity of the PTO system PTO position (rotary or linear) Electrical Power measurements (if applicable) Details In radians for rotary generators and m/s for linear generators If the PTO system has maximum limits of motion the position of the PTO system should be recorded and measured Voltage, Current, Power, etc. Power measurements may need to be in the kHz frequency range - Mooring System Performance Mooring System Performance Details Tension in each mooring line Mooring attachment angle at the mooringdevice connection point - Device Specifications Structural Specifications Component description Details CAD drawings of all device components - Mass - Center of mass - Moment of inertia about the center of mass - Device scale 1:25 – 1:100 for most devices Active or passive geometry control If the geometry is changed during testing, details should be provided. For example, if the ballasting is changed modified to change the natural frequency of the device. Hydrodynamic drag coefficients If available. Literature values can be used or CFD simulations can be run to estimate these coefficients if necessary. Decay Tests (Pluck Tests) with and without mooring attached Time resolved tests capable of obtaining the natural resonance and decay parameters in each obtainable DOF. Should be repeated with and without the mooring. PTO System Specifications Component description General specifications Damping and stiffness values Control strategy Details Mass, moment of inertia, rotation rate at different power outputs, etc. This will be important to consider if PTO gyroscopic effects influence device motions. If the PTO system settings are changed during a single test, details on the PTO system control strategy are needed. Dynamic Calibration Curves The dynamic characteristics of the tested PTO should be calibrated before integration into the device. Mooring System Specifications. Component description Details Configuration Line lengths, weight, stiffness, device connection points, seafloor connection points, etc. Stiffness and damping matrices Stiffness vs. displacement matrix and damping vs. velocity and displacement. Note: this is only needed if other mooring specifications are not provided Calibration curves Experimentally measured versions of the stiffness and damping matrices detailed above. Anchor specifications Type, mass, holding force, etc.