Quaker Chemical Corporation is a leading global provider of

advertisement

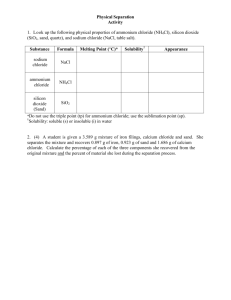

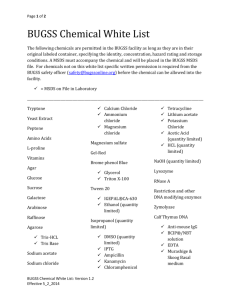

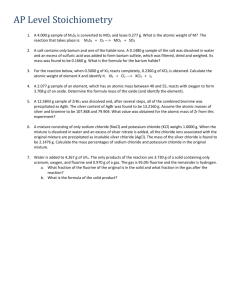

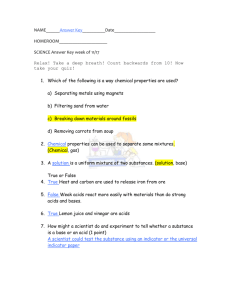

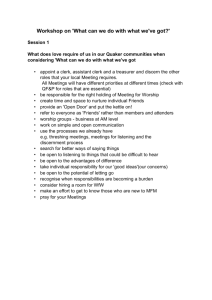

Quaker Chemical Corporation is a leading global provider of industrial lubricants, hydraulic fluids, drilling fluids and metalworking fluids. They provide approximately 350 different process fluids and associated services to a wide range of industries including steel, aluminum, automobile, mining, aerospace, tube and pipe coatings and building materials. Quakers headquarters are located in Conshohocken, Pennsylvania. Since 1962 the European headquarters are based in Uithoorn, the Netherlands and from 1963 it has worldwide offices in England, Italy, Australia, Japan, Spain, South Africa, Mexico and Canada. Many of the metal working products are emulsifiables. They consist of a lot of different, typically technical-grade, raw materials. These emulsions are offered as a concentrate to the customer, and mixed on site with water up to volumes between 1 and 100 m3. The water, used to emulsify these concentrates, is often not de-mineralized water, but on site available ground, river-, or drinking water. This water is often a source of pollution in the emulsions. To ensure the quality and functioning of the emulsions for the long period of which they are used over (often several years), various properties of the emulsions are monitored. Think of daily pH control, weekly microbe tests and monthly difficult microbe tests and more extensive analysis including chloride determination. Various techniques are available to determine the chloride concentration, which vary from gravimetric and potentiometric methods like titration, to high-tech methods as ion chromatograph, X-ray fluorescence (XRF) or inductively coupled plasma-mass spectrometry (ICP-MS). When chloride determination is applied to Quaker products varying of results are found. The variance is found between different methods, data from previous determinations, or data from other locations. This often leads to unresolved debates about the conditions of the products and makes the exact condition of the product unknown, which can lead to improper maintenance with potentially adverse consequences for the customer, as can be seen in figure 1. These consequences can be very serious, regarding the replacements of entire systems, corroded or damaged machinery and claims addressed to Quaker. Figure 1 Example of corrosion on costumer products Chloride determination has been an issue for quite some time at Quaker. Most of the time problems arise from differences between chloride concentrations measured by a costumer (who often not discloses its analytical methods), the analytical department at Quaker, and even between methods here. There is no problem in analyzing transparent, low content samples with the Marcherey-Nagel equipment (photometric water analysis), Most Quaker products though are non-transparent emulsions, so this method does not work here. The most used method to determine the chloride concentration at Quaker is titration with AgNO3,. This because it is a very simple technique that can easily be done at the small labs, available at the fabric. It is based on the reaction of Cl- with Ag+ titration, is an old method to determine chloride concentrations and can be influenced by a lot of other components that also react with silver. Ion chromatography is also a method that is used to analyze chloride, other ions and almost any other charged or polar molecule, it works good on different kinds of samples and especially on water. This method is based on high pressure liquid chromatography (HPLC) but then with the interaction of ions with material in the stationary phase of a column. So it would be very suitable to measure the chloride content of Quaker products, even though the columns for the ion chromatograph are not suited for injecting emulsions. Another method that can be used to detect chloride is X-ray fluorescence. What happens: Materials are exposed to short wavelength radiation (X- or gamma rays) to excite some of the atoms present in the sample. When an electron in the excited atom “falls down” in to a lower orbital, it emits a photon with the exact energy of the difference in energy of the two orbitals. This is effect is shown in figure 2. This photon is detected and from this exact energy the element, emitting this specific energy, can be identified and by the intensity of the photons the concentration can be measured . Figure 2 simplified mechanism of XRF