University of Toronto

advertisement

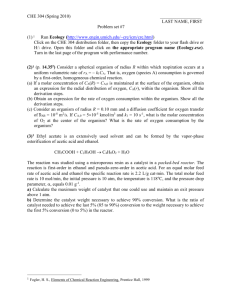

Name______________________ Student # ____________________ University of Toronto Faculty of Applied Science and Engineering Final Examination, April 15, 2014 CHE333S1 - Chemical Reaction Engineering Examiner: B.A. Saville Closed Book Examination-1 The Course Textbook or Official Course Notes Package may be used Calculators without a Graphical Interface may be used Both sides of the page may be used Question: Marks Possible Marks Earned 1 30 2 20 3 20 4 35 5 45 Total 150 Page 1 of 13 Name______________________ Student # ____________________ 1. Two 5000L CSTRs are available to process an exothermic liquid phase reaction A 2B. The reactor operates isothermally at 350K due to careful process control. Given the following: (-rA) = kAcA2; kA=8.2x104 e(-6,400/T) L mol-1 min-1 qo =75 L/min cAo = 2.5 mol/L MW(A) = 88 g/mol -1 -1 cP = 4.0 J g K MW(B) = 44 g/mol To = 35oC = 0.95 kg/L (-HRA) = -40 kJ per mol of A a. What is the maximum possible conversion of A using these vessels, under isothermal conditions? b. Assuming fA is less than 0.80, would these reactors require a heat transfer system in order to achieve the specified operating temperature? If so, does heat need to be removed or added to the system? Explain and justify your answer. c. What is the annual production rate of B (in tonnes), if fA = 0.80, the facility normally operates 24 hours per day, but is shut down for maintenance for 15 days per year? d. Would using a 10,000L batch reactor, also operating isothermally at 350K, likely produce a lower or higher conversion compared to your answer in (a), if the reaction time and residence time were equivalent, and the BR down time is 25% of the reaction time? Explain and justify your answer Page 2 of 13 Name______________________ Student # ____________________ Page 3 of 13 Name______________________ Student # ____________________ 2. You have been put in charge of a reactor/process design that aims to produce a partial oxidation product, B, from an initial reactant “A”. B can undergo further oxidation to compound “C”. Both reactions are first order. EA/R for the reaction A B is -5,500 J/mol, and for the reaction B C, -7,500 J/mol. You have the flexibility to choose the type of reactor(s), residence/reaction time, inlet reactant concentrations, operating temperature(s) and other design features, including separation equipment, heat exchangers, mixers, and stream splitters. a. What type of reactor(s) and operating conditions would you select in order to maximize the yield of B? EXPLAIN AND JUSTIFY YOUR ANSWER b. What type of reactor(s) (and other equipment, if necessary) would you choose in order to optimize based upon selectivity and feedstock utilization (i.e., fA), if the reactor operates isothermally? The rate constant for the first reaction, k1, = 0.35 min-1, and k2 = 0.040 min-1. Page 4 of 13 Name______________________ Student # ____________________ Page 5 of 13 Name______________________ Student # ____________________ 3. A reactor must be designed for a first order gas phase reaction A B + C . The feed contains equimolar amounts of A and an inert, at a total molar flow rate of 100 mol/min, and a volumetric feed rate of 650 L/min. The target fractional conversion is 0.80, and kA = 0.47 min-1. a) What residence time is required for a PFR in order to achieve the target conversion? b) Using the residence time calculated in (a), what is the conversion obtained from the segregated flow model? Either a calculation or discussion with justification is acceptable. Page 6 of 13 Name______________________ Student # ____________________ Page 7 of 13 Name______________________ Student # ____________________ 4. The kinetics for a catalytic first order gas phase reaction A products were studied. Pure reactant A was fed through the catalyst bed at 150kPa and 400oC, and the observed reaction rate was measured for several sizes of the spherical catalyst, ranging from 0.25 to 10 mm in diameter. The following data were obtained: dp, mm 0.25 0.50 1.0 5.0 10.0 (-rA)obs, mol L-1 h-1 175 180 155 59 30 1. Determine the effectiveness factor and shape-independent Thiele modulus (’) for the 1 mm and 5 mm particles 2. Determine the effective diffusivity (De), the intrinsic reaction rate constant (kA) and intrinsic reaction rate for this process 3. Predict the observed reaction rate for a bed of 25 mm (dp) catalyst particles (justify your answer). 4. Predict the impact on the Thiele modulus and the effectiveness factor if the process was instead conducted at 500oC (explain and justify your answer). Page 8 of 13 Name______________________ Student # ____________________ Page 9 of 13 Name______________________ Student # ____________________ 5. A three stage fixed bed catalytic reactor is to be designed to convert SO2 (A) into SO3. The equilibrium curve is presented on the next page. Within each stage, the operation is adiabatic and isobaric, and between stages, the temperature is adjusted by 100K using heat exchangers. The outlet temperature from each stage is at least 15K less than the corresponding equilibrium temperature. The feed contains 10 mol% SO2 (A), 12 mol% O2, 77.9% N2, and the balance is SO3.The inlet temperature to the system is 677oC. The catalyst sinters at 800oC. Assume that the pseudohomogeneous one-dimensional plug flow model is valid. a. Determine the temperature and fractional conversion at the outlet of each stage, and b. Assuming the outlet conversion from stage 1 is 0.30, estimate the catalyst mass required in this stage. Use a step size of 0.10 for fA. c. Considering your answer in part (b), how much catalyst would be required if the Thiele modulus (’) was 0.10? Explain/justify your answer FAo = 10000 mol/min; m = 3215 kg/min; cP = 0.94 J g-1 K-1; Po = 100 kPa; HRA = -95 kJ/mol; B = 500 kg/m3 Kp = 8.0 x 10-5e12,100/T MPa-1/2 with T in Kelvins kSO2 = 1.84 x 1011 e-26000/T mol SO2 (g cat)-1 min-1 MPa-1 with T in Kelvins r SO2 p SO2 k SO2 p SO 3 1 2 2 p SO3 pO 2 p SO2 K p Page 10 of 13 Name______________________ Student # ____________________ Equilibrium conversion vs temperature relation: SO2 oxidation 1 0.9 0.8 fractional conversion 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 700 750 800 850 900 950 Temperature, K Page 11 of 13 1000 1050 1100 1150 1200 Name______________________ Student # ____________________ Page 12 of 13 Name______________________ Student # ____________________ Page 13 of 13