BBEP:NEWBio Workshop Eco-Friendly Packing Peanuts: Making

advertisement

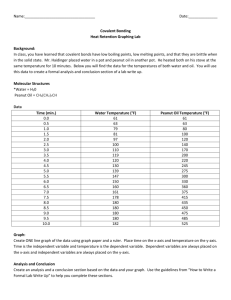

BBEP:NEWBio Workshop Eco-Friendly Packing Peanuts: Making Them and Putting Them to the Test July 2015 Creating the Most Effective Biodegradable Packing Peanut Consider alternatives to petroleum based products. Create a more sustainable packing peanut option, instead of Styrofoam. Using a basic starch recipe, determine the ratios of glycerol and baking powder that should be used to create a more effective packing peanut. Compare the effectiveness of Styrofoam and biodegradable packing peanuts. Scientific Practices: Ask questions about the environmental impact of the current model of packing peanut production and usage (Why should we worry about eco-friendly alternatives?) Plan and carry out investigations about how to make starch-based peanuts (based on the underlying chemistry) with varying sources and ratios of starch and other inputs (how do the properties of the starch products change based on the inputs and conditions?). Construct explanations based on lab-generated evidence, and observations of core information o about hydrogen bonding, polarity, structure and function of molecules, etc., for the properties and utility of starch-based packing peanuts. Develop a solution to quick and safe shipping of fragile items with starch-based peanuts. (How o can we use our knowledge of the chemical properties of starch to make more effective and ecofriendlier shipping equipment?) Engage in debates based on evidence and scientific theory about the social, economic, and environmental benefits of building a large scale industry for starch-based production. Background: Petroleum Based Peanuts Created from polystyrene A molecule made up of many repeating units of styrene Styrene is produced using petroleum. 45 million pounds of polystyrene packing peanuts are manufactured each year. There is no evidence of biodegredation. Starch Based Peanuts Created from repeating units of glucose, a natural polymer found in plants. Starch-based peanuts can be disposed of by dissolving the peanuts in water. Baking Powder • When dissolved in water, acid salts reacts with sodium bicarbonate and produces carbon dioxide. Carbon dioxide creates bubbles within the mixture forming gas pockets. Glycerol • A plasticizer that gives plastics flexibility and durability. Water was used in the standard. Glycerol (derived from vegetable oil or animal fat can be used to alter the stiffness of the starch peanut. 1 Investigation 1: Creating Effective Biodegradable Packing Peanuts Challenge: How can the chemical composition be changed to create a “better”, more effective biodegradable packing peanut. Materials Needed o o o o o o o Corn starch Baking powder Glycerol Water Paper cups Measuring spoons Microwave Procedure: Teachers will use a standard set of procedures to create the first biodegradable peanut. Part 1: Standard Trial 1. Add 1 tablespoon of corn starch to a paper cup. 2. Add 1 tablespoon of tap water to the same paper cup. 3. Stir this mixture until all the hard clumps are gone and it becomes watery. 4. Microwave the paper cup for 30 seconds. (Note: this time may vary with different microwaves.) 5. Take the paper cup out of the microwave and let cool. 6. Once the cup has cooled down enough to hold, peel the paper cup off the starch. 7. Record your observations of the resulting starch peanut in the box below. Cornstarch Standard 1 Tablespoon Water 1 Tablespoon Glycerol -- Baking Powder -- Trial 1 Trial 2 Trial 3 Microwave power level Time in microwave Standard Trial Part 2: Trial 1-3 2 Each group will try at least 2 different variations (more if time allows) in chemical composition. The following additional chemicals are available to use: Glycerol and baking powder Background Information: Baking Powder • When dissolved in water, acid salts reacts with sodium bicarbonate and produces carbon dioxide. Carbon dioxide creates bubbles within the mixture forming gas pockets. Baking powder will make the peanut fluffier. Glycerol • A plasticizer that gives plastics flexibility and durability. Water was used in the standard. Glycerol (derived from vegetable oil or animal fat can be used to alter the stiffness of the starch peanut. Glycerol will make it flexible. With a partner, create a more effective packing peanut using one or more of the additional materials. Record the specific amounts of each ingredient in the table and be prepared to explain the reasoning behind your choices. Trial 1 Observations Trial 2 Observations Trial 3 Observations (If time) Patterns and Observations: With your partner, discuss which peanut composition created the best packing peanut. What evidence can you state to support your decision? Write down you answer below. 3 Comparing biodegradable and Styrofoam packing peanut effectiveness Guiding Question: How does the effectiveness of packing peanuts compare between Styrofoam (polystyrene) and biodegradable (starch-based) peanuts? Materials: o Polystyrene peanuts o Starch peanuts o Cardboard boxes o Eggs o Ziploc bags o Packing tape Procedure : Prepare a box for each type of packing peanut: 1. Fill half of a cardboard box with packing peanuts. 2. Place an egg in a Ziploc bag to contain any leakage. a. Students can do additional modifications to the Ziploc bag, such as stuffing it with peanuts, as long as they do the same treatment for both peanut types. 3. Place this bag in the center of the box and fill the rest of the box with packing peanuts. Be sure to fill up all the empty spaces to ensure that shifting of the egg is minimized. 4. Close the cardboard box and use packing tape to close the flaps on the box. Egg drop: 5. Drop each of the boxes from a particular height. Open each box and examine the egg after impact. If a student’s egg cracks, have them record the height at which the egg cracked and which packing peanut treatment was used. 6. Seal up the boxes with intact eggs and repeat step 5 at a greater height. 7. Repeat step 6 until there are no more intact eggs. Observations and Patterns: a. Based on these results, which packing peanut performed better? 4