3D Printer and Scaner

advertisement

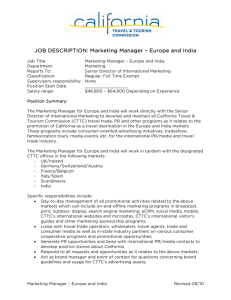

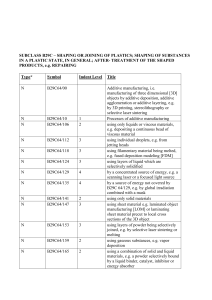

ANNEXURE-I Central Tool Room & Training Centre Bhubaneswar Technical Specification of 3D-Printer Maximum Printable Area Filament Diameter Extruder Diameter Extruder Temperature Number Of Extruders Material Support Print Accuracy Maximum Print Speed Layer Precision Heat Bed Bed Temperature LCD Support SD Card Support SD Card Memory Total Machine Weight Packing Size ( cm ) Power Supply Unit Run Time Change Setting Option Pause Print Option (X) 305 mm x (Y) 205 mm (Z) 575 mm - ( 12"× 8" × 23" ) or more 2 mm to 5 mm 0.4 mm to 0.5 mm 50 °C to 240 °C or less 1 ( Anti Jam Queen Bowden Style Extruder ) PLA, Soft PLA, Flexible, WOOD , PVA 15-20 microns 300 mm / second or more 0.03 mm to 0.4 mm No NA Yes (Colour) Yes 8 GB 29 Kg (61 x 57 x 95) maximum Outside 110-240V, 50/60Hz, 2-2.2A(input), and takes standard IEC cable Nozzle Temperature, Fan Speed, Print Speed, Feed Rate Yes ( This can be used for changing the filament ) ANNEXURE-II Central Tool Room & Training Centre Bhubaneswar Technical Specification of 3D-Scanner Architecture Measurement System: Proprietary MultiStripe Laser Triangulation (MLT) technology Source: Twin arrays of four, Class 1M, 10 mW solid state lasers with custom optics 650 nm I. Sensor: Twin 3.0 Megapixel or more CMOS image sensors. Photo Surface: optically synchronous 7-color surface capture for precision-locked geometry correlation. Auto Drive: High precision rotary servo positioner, auto-controlled by scanner. 20 lb max. Part Gripper: Universal part holder to adjust height, angle, and orientation of capture. 10 lb capacity. Performance Object Size: No preset limit. Objects larger than field can be assembled with supplied software. Field Size: 5.1" x 3.8" (Macro) and 13.5" x 10.1" (Wide). HD PRO Extended Mode 22.5" x 16.75"minimum. Resolution: 3D point density on target surface is 400 DPI minimum in Macro Mode and 150 DPI minimum in Wide Mode. Texture Density:400 DPI on target surfaces is 400 DPI minimumin Macro Mode and 150 DPI minimumin Wide Mode. Dimensional Accuracy:±0.005" in Macro Mode minimumand ±0.015" in Wide Mode minimum. Acquisition Speed: 50,000 or more processed points/sec throughput. Typically 2 minutes or less per scan of each facet. Typical Datasets : Typical small models are a quarter million points, after oversampling and optimization Minimum System: Compatible with Windows7 32-bit and USB interfacing Interface: USB 2.0 high speed interface. USB cable included. Power: 100 - 240 VAC built-in worldwide auto-switching power supply. AC cable included. Eye Safe: Beam is about 1/1000th brightness of a laser pointer (but avoid looking into the beam). Tripod Mount:Stainless steel 1/4 - 20 thread standard screw mount for tripod setups. Size: Compact 8.8" x 3.6" (letter size) desktop footprint. 10.9" high. Approximately 7 lbs Software Scan : Control scanner & auto drive Align : Automatic alignment of scan sets Fuse : Merge scan into single mesh model Processing (2x speed) : :Smart further reduce edge artificates& noise 4x sampling : Higher quality points through over sampling 7 Colour : 7 channel colour capture for high accuracy Large area Ultra wide mode depth range over 30 inches 4x Density 4 times more point (4 million approx.) Rapid work : GUI direct output to PROE/CREO, UG-NX, Solid works, AutoCAD, etc. ANNEXURE-III Central Tool Room & Training Centre Bhubaneswar Course content for Skill Development The course should comprise of the following: Additive technology and its difference from conventional manufacturing. Different technologies used in additive manufacturing SLA, SLS, FDM. Preparing the model for rapid manufacturing. Role of the support material and optimizing the additive manufacturing Different material and their properties Adjustment of speed, temperature for accuracy and matching the properties of the material Time estimating the production time of the job Applications of additive manufacturing Assembly of the FDM system Scanning technology Different type of scanners-white light, blue light, laser scanners, multiple beam laser scanners, robot arm scanners etc. Scanning for different type of objects like small and large components, stationary objects like building and monuments, special purpose scanning for aircrafts and bridges for Rivet inspection etc. Preparing the object for scanning Capturing the cloud data for small and large objects Synthesizing the model with overlap Creating CAD model from the cloud data Modifying the model to suit the design requirement Printing the model for checking form and fit Design verification tools Inline inspection tools for QA ANNEXURE-IV Central Tool Room & Training Centre Bhubaneswar TRAINING: The course may be divided in two parts of 75hours each. The student can attend the course on rapid prototyping and then take second course in Reverse engineering. The sequence can be reversed as well. CTTC Bhubaneswar will start one month (75hrs) skill development course in 1- Rapid Prototyping (75 hrs). 2- Reverse Engineering (75hrs) for the degree/diploma Students. The Course will run simultaneously i.e. one in morning session and the other in afternoon session .The Vendor has to depute expert faculties for smooth conduct of the courses at CTTC Premises. Lodging & Boarding facility in CTTC Guest House will be provided by CTTC free of Cost. CTTC Faculties will also be trained along with the first batch of trainees. The Vendor has to quote for the same.