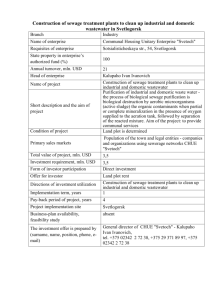

2. Design of the sewerage network

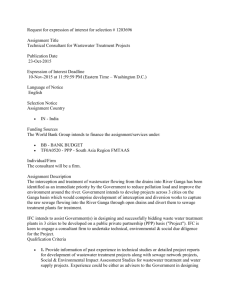

advertisement