Kalamazoo Water Reclamation Plant

advertisement

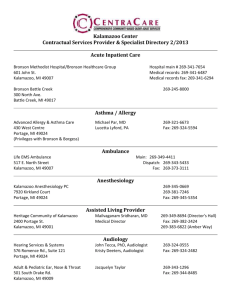

PROJECT EXPERIENCE CITY OF KALAMAZOO KALAMAZOO WATER RECLAMATION PLANT – INDUSTRIAL PLASTICS AND MUNICIPAL SCREENING STUDIES / FINE SCREEN FACILITY Kalamazoo, Michigan The Kalamazoo Water Reclamation Plant (KWRP) requested an engineering study to investigate alternatives to improve the removal of industrial plastics from the discharge of a recycled paperboard mill. The KWRP receives industrial wastewater from the adjacent paperboard mill through a dedicated interceptor sewer. The mill provides primary treatment before discharging the wastewater to the KWRP. Prior to mixing the industrial wastewater from the mill with the KWRP municipal raw sewage, it is screened through a Hycor Rotostrainer® system located in their Industrial Screenings Building. The screens have generally been ineffective in removing the finely chopped plastic material and consequently the material is causing Project Elements problems in downstream processes. The plastics have been found accumulated in the Industrial Pre-treatment Industrial Wastewater Screeningwastewater influent structures, plugging the plant effluent water system, intermixed Screenings Handling with sand media in the tertiary filters and in the sludge. Updated mm/dd/yy w Equipment Layout in New & Existing Building Key Team Members Jim Broz Jeff Glover Services Engineering Study Period of Services 07/2003 to 12/2003 Cost: $19,968 – Industrial Study $24,900 – Municipal Study $149,977 – Design $84,136 – CPS $2.213 M – Fine Screen Const. Cost Client Reference Mr. Larry Fisher Assistant Plant Engineer 269-337-8771 BLACK & VEATCH The study concluded that retrofitting or modifying of the existing screening system or the Paperboard mill treatment facility is not recommended and due to the nature of the plastic material, removal at the source, grinding, chemical treatment, clarification and skimming are not effective removal methods. The findings indicated that screening is the most effective method of removal. The Plant retained B&V to perform a study of the municipal screens and consider the replacement of the existing course screens and/or the addition of fine screens to resolve the finely chopped plastic material problem. The study developed several course screen replacement and new fine screen alternatives as well as researched screening and processing equipment. The study recommended the perforated plate band screen as it the highest removal efficiency and is best suited to capture the plastic material. Additionally, the study recommended replacing the course screen with similar screens to remove the large objects and construct a new Fine Screen Facility down stream to remove the finer material. Subsequently, the KWRP plant staff requested B&V prepare construction documents for the construction of a new Fine Screen Facility located downstream of the existing course screens and grit chambers. The new facilitates included three 30 mgd band screens and screenings processors that discharge into roll-off disposal containers. The new equipment is located inside a new pre-engineered metal building that was partially built on existing Primary Tank influent channels. The new metal building includes an HVAC system, odor control (exhaust only), PEW system and electrical Pursuit Name • 1 PROJECT EXPERIENCE CITY OF KALAMAZOO and instrumentation systems. The new electrical gear (MCC, controls, etc) was installed in the existing Blower Building adjacent to the Grit Tanks. Site improvements included extension of underground sanitary sewer, PEW piping and electrical service and above ground odor control, replacement of site access road at new building, new concrete pavement and other minor improvements. The Fine Screen Facility was put in operation in February 2007. Updated mm/dd/yy w BLACK & VEATCH Pursuit Name • 2